So when in 1971, i saved up snow shoveling and lawn money to buy my first mini bike. went to Kelly's mini bike shop in Rochester NY, and for some odd reason, ended up buying a Broncco TX2 (orange.) Here's a picture of me and my new bike:

When I got back into mini bikes, i never thought i would come across any Broncco stuff. And frankly, I wasn't really jonesin' for a Broncco either. I always liked my neighbor's Rupp roadster and other neighbor's Honda ct70. They seemed way better (and in fact were.) I have since re-done a bunch of Rupps (you can't throw a rock without hitting one around here, they are everywhere.) But i ended up tripping across a couple Bronccos, and thought, what the heck, maybe i should re-do these. So i bought a Tx1 and a Tx2:

The one thing I always hated about my original Tx2 was the lack of rear suspension. So a couple years after I bought my first mini bike (probably 1973), I noticed my neighbor had a 'roller' (we didn't call them that) in his garage and it was a 1970 green broncco Tx2 (front and rear suspension). He sold it to me for $13, with no engine and a torn seat. I stripped all the good parts off my Tx1 and put them on the Tx2, and added a torque converter. It was a pretty awesome mini bike! I could finally almost keep up with the Rupp neighbor and his Roadster.

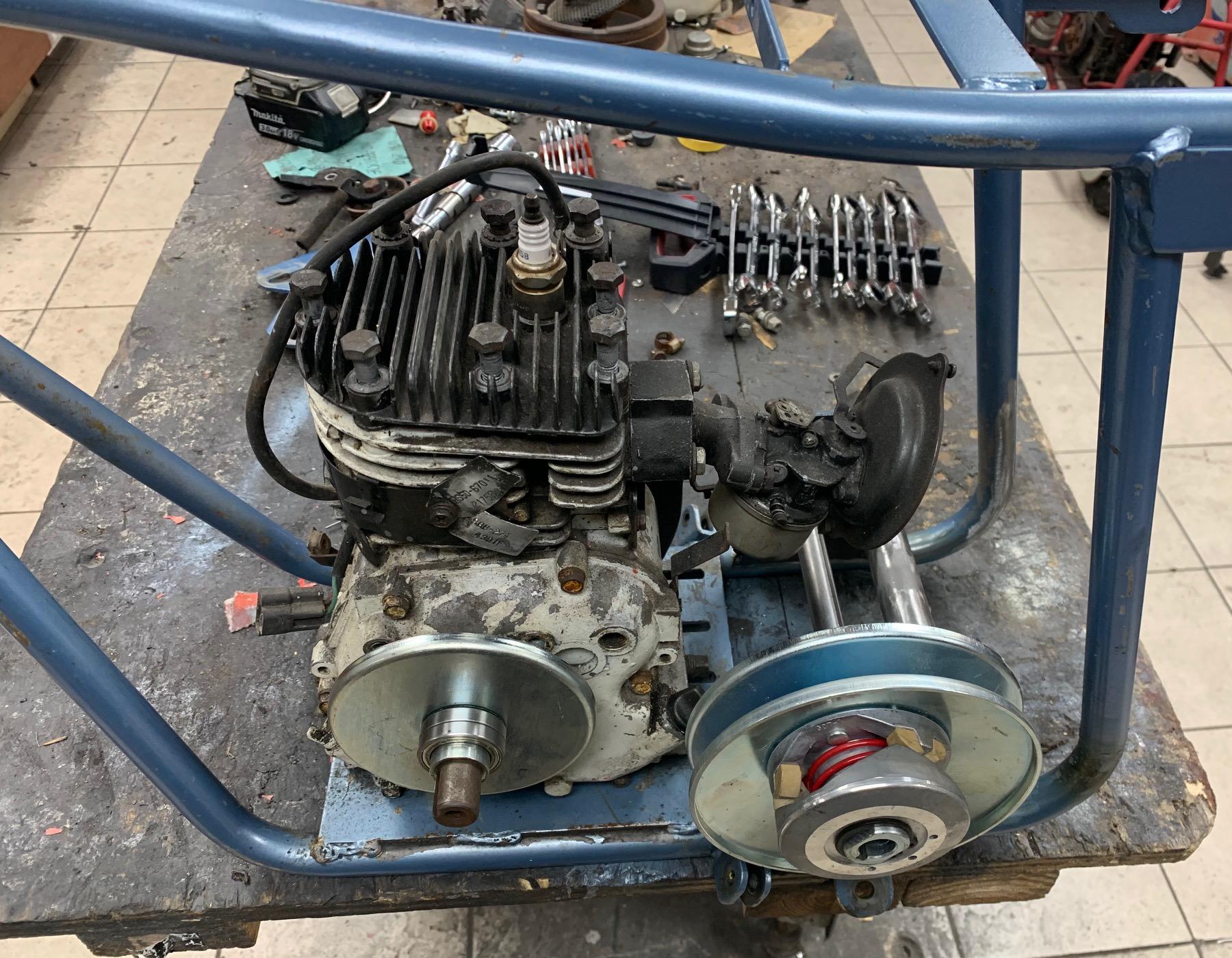

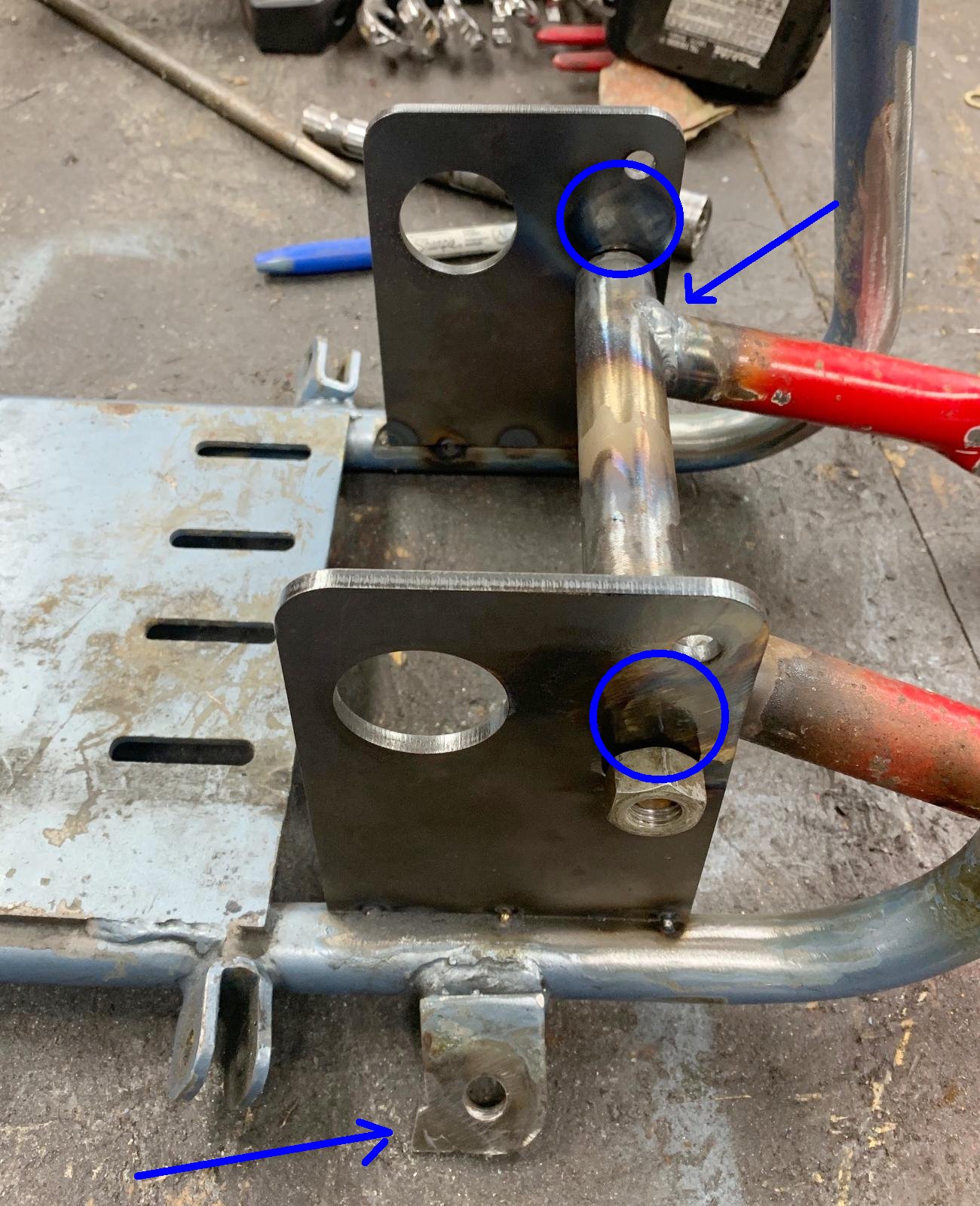

So what I'm going to do here is use the 1970 green Tx1 in the picture above as a guide (only), and turn the blue 1970 Tx2 into a Broncco Tx1. Will have to add a swingarm and a jackshaft. Probably some other stuff too. Will also install a torque converter. I've been buying Bronco parts as they come up on ebay, they are pretty hard to find.... I'll put a Tecumseh HS50 motor on the Broncco with a nice UAxx Dellorto carb (it's an Italian mini bike, must have a Dellorto.) I'm not sure how 'stock' it will all look, but i'm going to try and mimic the green Tx2.

Sorry about the lack of shoes. Instead I put my Vintage Flipper World coffee cup in the picture. i thought you could use any personal item. Maybe i'll go back to the shop and take another picture with a shoe...

When I got back into mini bikes, i never thought i would come across any Broncco stuff. And frankly, I wasn't really jonesin' for a Broncco either. I always liked my neighbor's Rupp roadster and other neighbor's Honda ct70. They seemed way better (and in fact were.) I have since re-done a bunch of Rupps (you can't throw a rock without hitting one around here, they are everywhere.) But i ended up tripping across a couple Bronccos, and thought, what the heck, maybe i should re-do these. So i bought a Tx1 and a Tx2:

The one thing I always hated about my original Tx2 was the lack of rear suspension. So a couple years after I bought my first mini bike (probably 1973), I noticed my neighbor had a 'roller' (we didn't call them that) in his garage and it was a 1970 green broncco Tx2 (front and rear suspension). He sold it to me for $13, with no engine and a torn seat. I stripped all the good parts off my Tx1 and put them on the Tx2, and added a torque converter. It was a pretty awesome mini bike! I could finally almost keep up with the Rupp neighbor and his Roadster.

So what I'm going to do here is use the 1970 green Tx1 in the picture above as a guide (only), and turn the blue 1970 Tx2 into a Broncco Tx1. Will have to add a swingarm and a jackshaft. Probably some other stuff too. Will also install a torque converter. I've been buying Bronco parts as they come up on ebay, they are pretty hard to find.... I'll put a Tecumseh HS50 motor on the Broncco with a nice UAxx Dellorto carb (it's an Italian mini bike, must have a Dellorto.) I'm not sure how 'stock' it will all look, but i'm going to try and mimic the green Tx2.

Sorry about the lack of shoes. Instead I put my Vintage Flipper World coffee cup in the picture. i thought you could use any personal item. Maybe i'll go back to the shop and take another picture with a shoe...