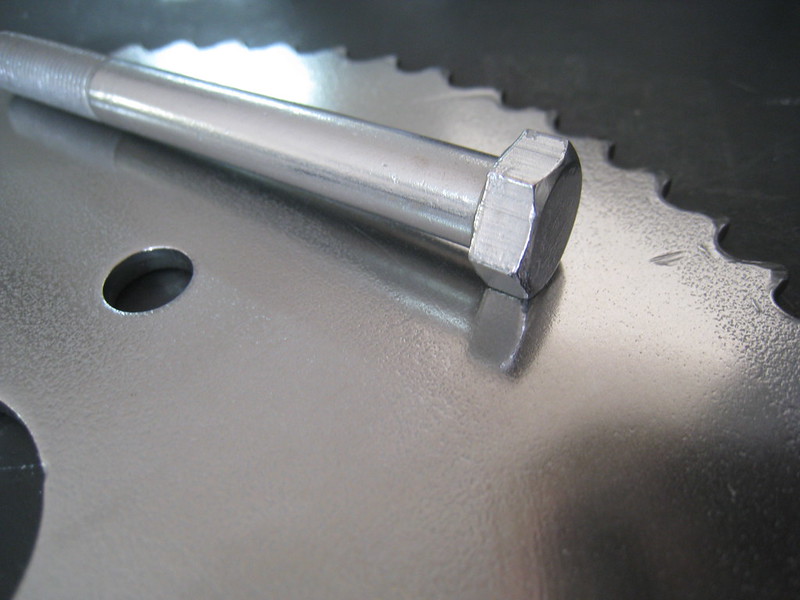

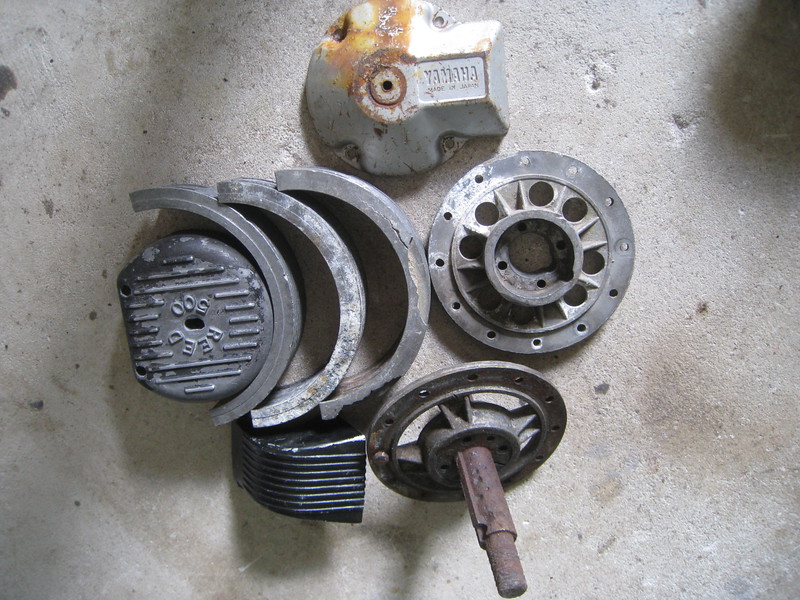

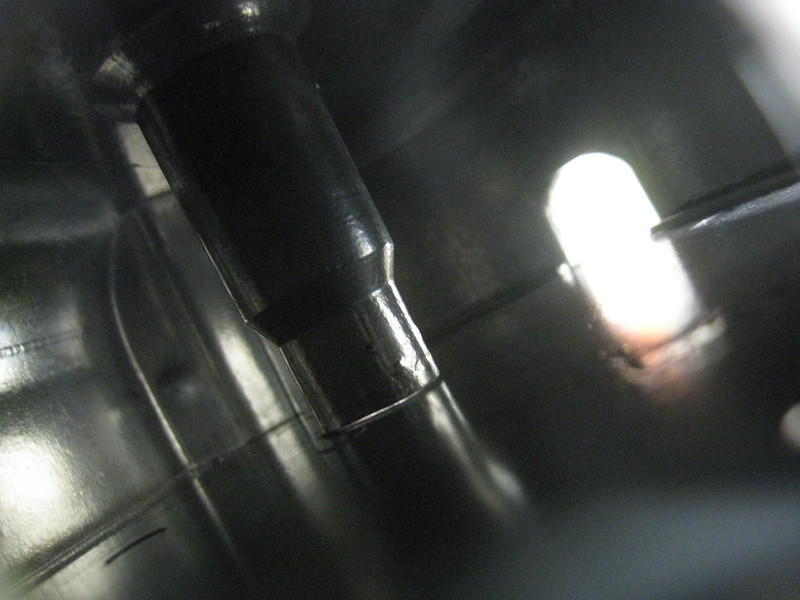

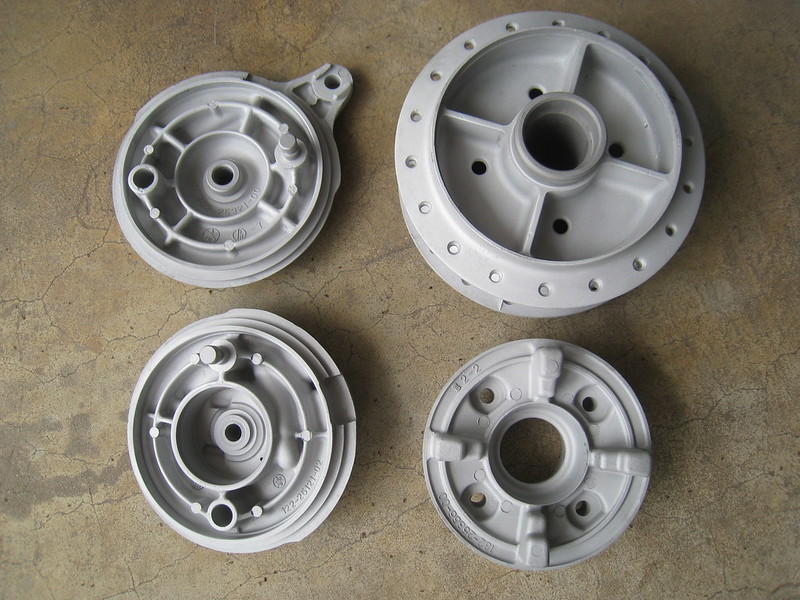

I've had a few jobs like JJ's and Manchester's which have some steel parts in them. There is no problem with burnishing them and they look great when done. Time to time I get a PM about what to do next with the steel parts?

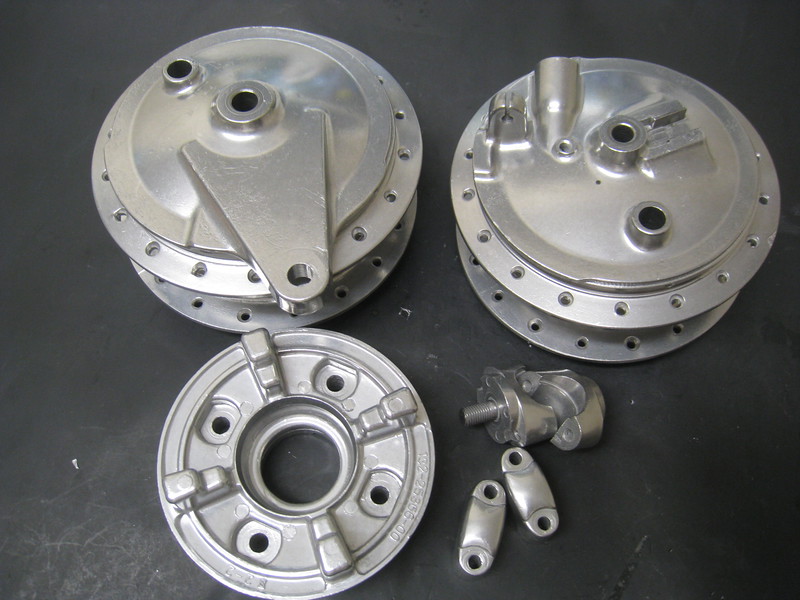

I think clear zinc makes the most sense in most cases. Remember though they will be dipped in acid just before the zinc plating and this can dull the burnish. No big deal.

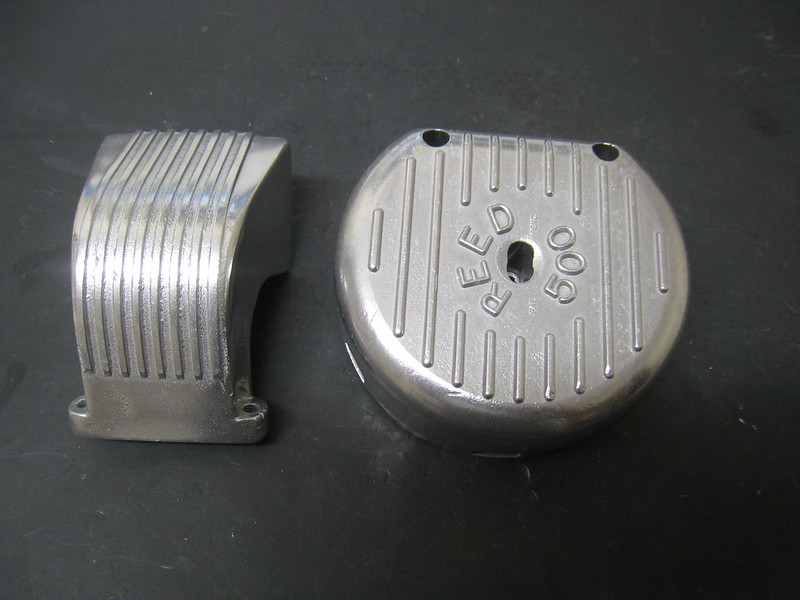

I'm a big fan of nickel plating over a burnish finish because it's just reflective enough give some extra "wow". Nickel is pretty tough too, but would require occasional polishing. It seems to reflect a warmer color of light.

Chrome is a candy thin coating over nickel or bare steel. It actually protects the nickel in the conventional plating process. Chrome reflects a very realistic band of light.

Cadmium is period correct in a lot of older materials, but is also pretty week from my experience.

I've worked with Ted Tine at ted@tedtine.com in CT. I do burnishing work for him and he does plating for me. We've been talking about the need to have access to low volume plating services like what I do here. I'd invite anyone here to reach out to him with plating questions. He is in our hobby and goes by margay here on the forum.

I think clear zinc makes the most sense in most cases. Remember though they will be dipped in acid just before the zinc plating and this can dull the burnish. No big deal.

I'm a big fan of nickel plating over a burnish finish because it's just reflective enough give some extra "wow". Nickel is pretty tough too, but would require occasional polishing. It seems to reflect a warmer color of light.

Chrome is a candy thin coating over nickel or bare steel. It actually protects the nickel in the conventional plating process. Chrome reflects a very realistic band of light.

Cadmium is period correct in a lot of older materials, but is also pretty week from my experience.

I've worked with Ted Tine at ted@tedtine.com in CT. I do burnishing work for him and he does plating for me. We've been talking about the need to have access to low volume plating services like what I do here. I'd invite anyone here to reach out to him with plating questions. He is in our hobby and goes by margay here on the forum.