As I said earlier, I am going to swap the weld-on rear axle support tabs for "bushings" in order to make it look better, have access to the axle nuts, and give me more room in front of the rear tire for jack shaft components.

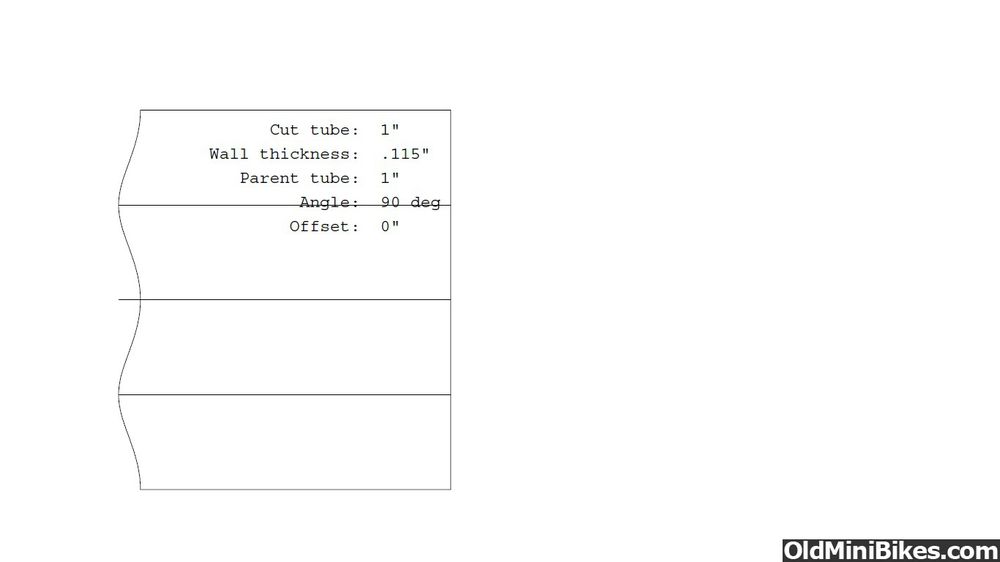

I went to "Metal Geek's"

coping calculator and printed a pattern for coping. (Fishmouth) Wow, what a time saver! I cut it and taped it to the frame and shot some primer over it to mark out the area needed to be cut away. In this case, I am working with 1" .115 thick wall, and installing bushings with a 1" OD.

Pattern:

It obviously isn't the usual 45 or even 35 degrees!

Darn that is a bad photo!

I had to level the frame, paint the tube ends with SEM guide coat, then ran a straight edge along it. This gave me my 12:00 O'clock line. The pattern from Metal Geek has that line on it, so alignment was easy. I cut it with my trusty Makita angle grinder. Yes, I am a GARAGE HACK!

Coping cuts. Used pattern in the middle.

It's not saying much, but this is as close as I've got one of these. The entire process took me about half an hour.

I will use a 12" long piece of bushing stock and weld it in to ensure level, and square with the frame, as well as to ensure the axle will go into one hole and actually come out the other hole without binding.

Beat THAT with your CNC and water jet cutter! (Just kidding, but I am one bad motherscooter with an angle grinder!)

:laugh::laugh::laugh:

:drinkup::drinkup: