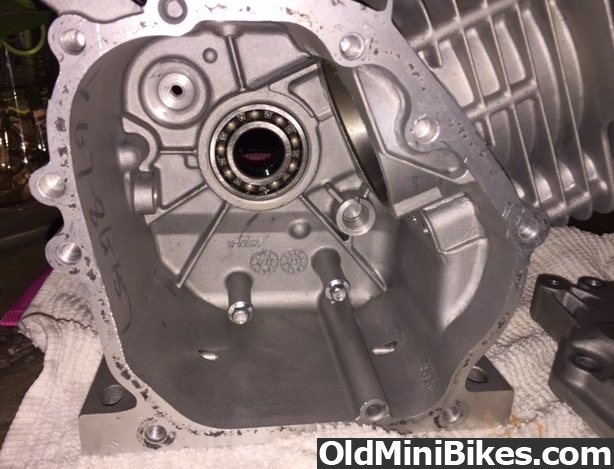

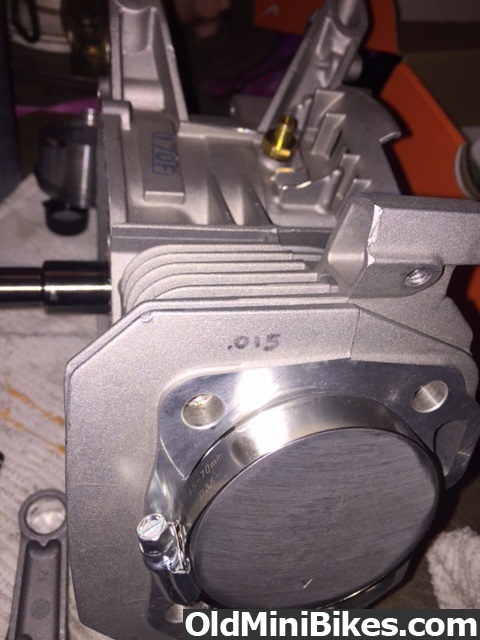

I tried selling this motor a while back and no luck, so I am just going to build this and document the progress in this thread. This motor is a hemi bottom end with a non hemi clone 18CC head:

ARC +.040 rod

Hemi flat top piston milled .005

pop up is +.015(above deck)

Will be using a .045 fire ring head gasket

Head is 16.3 CC for 12:1 compression

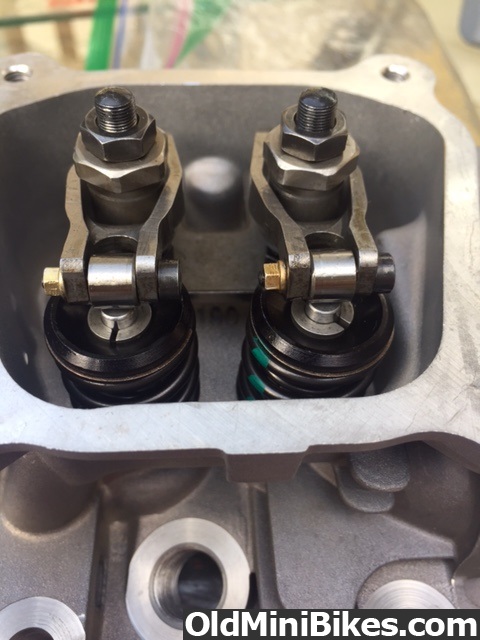

28/25 SS valves

dual springs

1.2 Ratio rockers

Hardened pushrods with guideplate

Will be running a black mamba sr cam

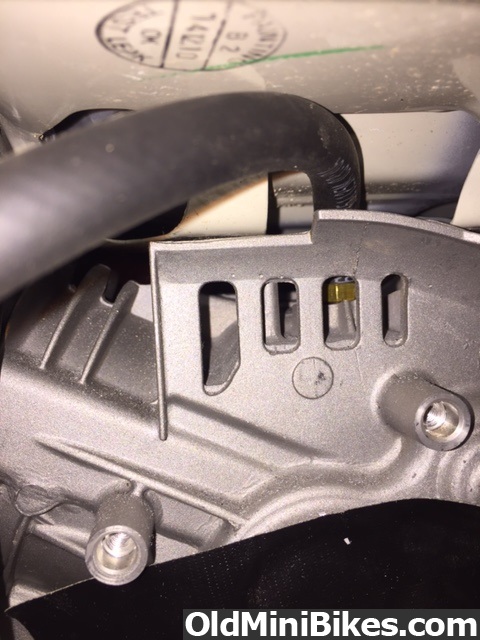

Debating on running a genuine honda side cover or the hemi cover at the moment.

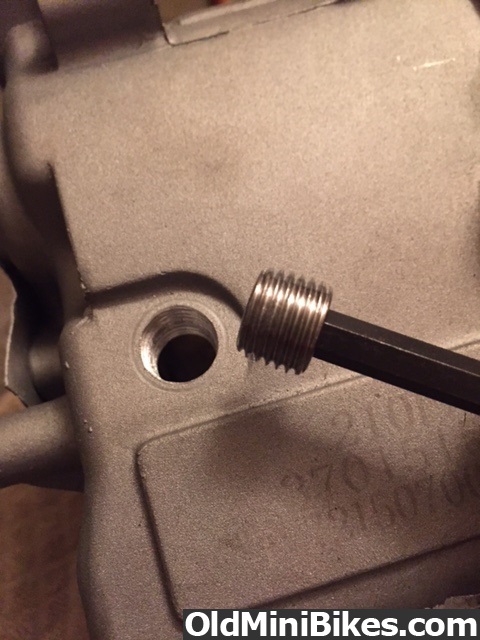

I am waiting on a 3/8 barbed hose fitting for crankcase venting currently.

Progress so far:

ARC +.040 rod

Hemi flat top piston milled .005

pop up is +.015(above deck)

Will be using a .045 fire ring head gasket

Head is 16.3 CC for 12:1 compression

28/25 SS valves

dual springs

1.2 Ratio rockers

Hardened pushrods with guideplate

Will be running a black mamba sr cam

Debating on running a genuine honda side cover or the hemi cover at the moment.

I am waiting on a 3/8 barbed hose fitting for crankcase venting currently.

Progress so far: