That may be the case. I haven't built an HS50 in a long time, but all the ones I fooled with back in the day were big valve engines, but they were points engines too, so that may be the case.

Does anybody know when the first OHH engines came out? I became aware of them in the early to mid 90's. (Maybe 93 or 94)

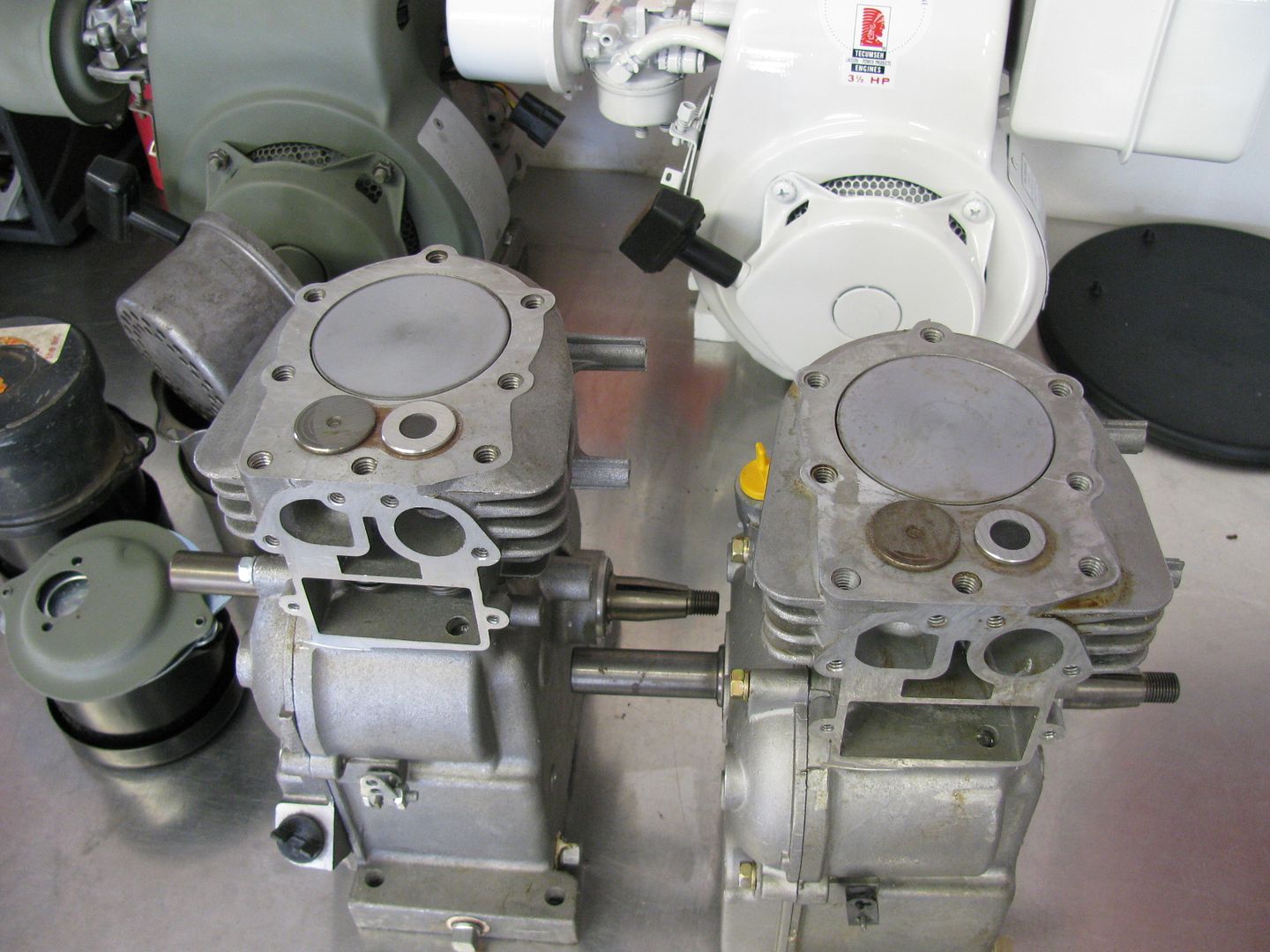

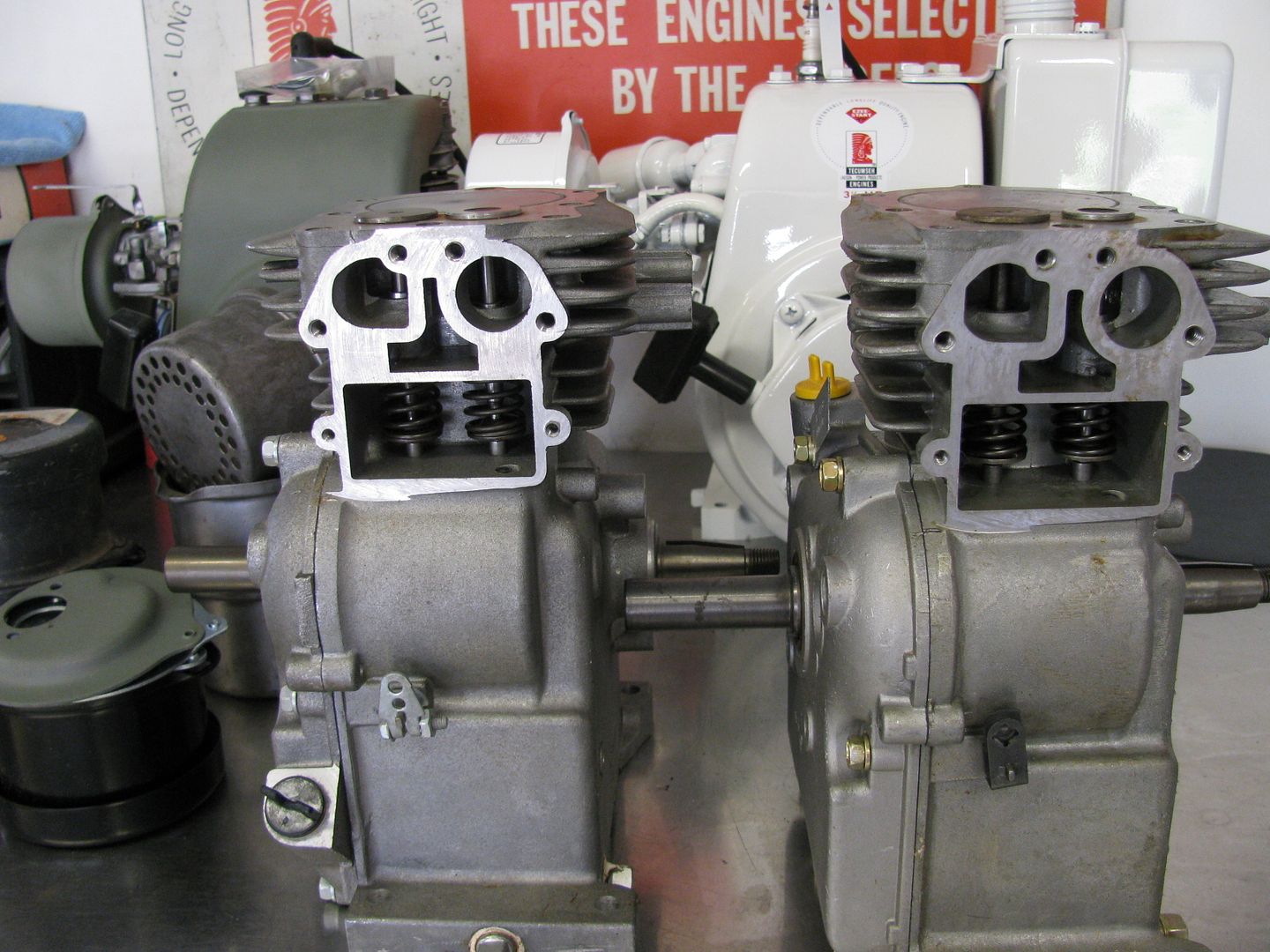

I bought one at the local lawnmower shop to see what was up with them and what I could do with one, and when I realized the internals of my HS engines fit them, that pretty much ended my HS involvement.

Does anybody know when the first OHH engines came out? I became aware of them in the early to mid 90's. (Maybe 93 or 94)

I bought one at the local lawnmower shop to see what was up with them and what I could do with one, and when I realized the internals of my HS engines fit them, that pretty much ended my HS involvement.

Based on some of my Ariens records, it looks like Tecumseh OHV started to arrive on the 932 series,

the compact series, in late Summer to Fall 1998, which would be the Model Year 1999 snowblowers.