Progress! The chrome came back and no surprise, it was expensive! The good news is that it came back quickly and was nicely done.

The scrubber brake is missing in all the attached photos. That's because the one I had was so bent up that it would not be worth trying to straighten. Thanks to Chipper for a scrub brake in excellent condition! It will be welded into place once I get the rust pits taken care of on the frame.

The two speed clutch came together pretty nicely - from several sources, but I have a few questions for the many experts out there:

1) Please look at the photos. The original jackshaft used snaps rings to hold certain parts, but I am using lock collars. Once I am certain everything lines up just right I'll machine the slots for the snap rings. By the way, if anyone sees any problems in my jackshaft stack-up, please advise.

2) The bearings on the jackshaft ends should probably press into place with a bit of friction, but these spin pretty freely. I suspect that I’ve lost a bit of material to rust over the years and that’s not helping. Any thoughts on locking down the bearings are appreciated.

3) On the drive shaft clutch the directions say that it is designed for the open side of the clutch to face toward the motor, the opposite of the typical case where the open side of the clutch faces away from the motor. The problem is that I cannot get the sprockets on the PTO shaft to align with the sprockets on the jackshaft unless I mount the driver clutch in the typical position. Is there a problem mounting the driver clutch as seen in the photos?

The frame has been media blasted and reveals some serious pitting as I expected. I can do a lot of grinding or use a lot of body filler (or both) to deal with the pitting, but any ideas on this topic are appreciated.

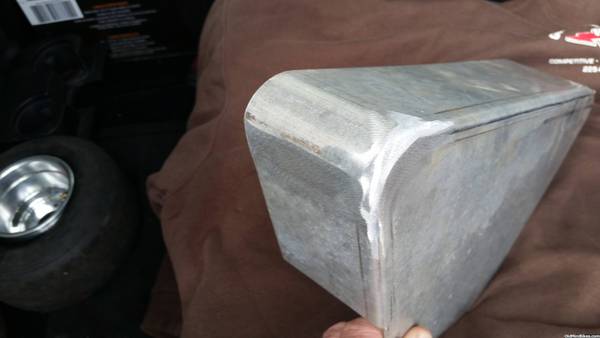

The fuel tank was really rusty inside. After rust removal, soldering and sealing it appears leak-free and functional. The good news is that the outside is pretty much dent-free.

Finally, the front shock springs have been a real problem. Getting springs to clear the struts and still fit into the end cups is the challenge. The original springs were a pretty light gauge, but any springs I’ve found are heavier and either the OD or the ID or both are wrong. Any thoughts on a front shock spring source are welcome.