Performance Coil For Predator 212

- Thread starter Jockey

- Start date

This makes no sense to me either .have you changed the spark plug?

These coils just don't burn out..

I guess change your coil again and spark plug and inspect or replace kill switch. .

These coils just don't burn out..

I guess change your coil again and spark plug and inspect or replace kill switch. .

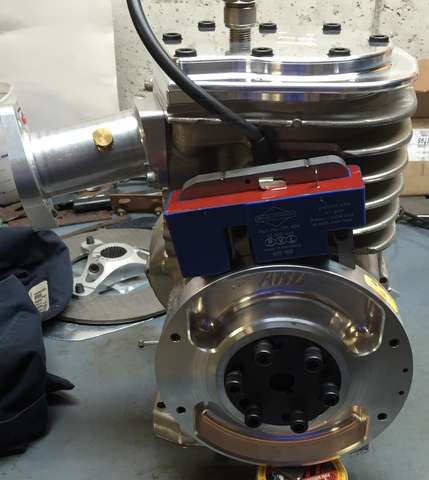

Actually do you have pic of this engine?

It's got a lot of machine work done along with custom ground cam, lots of compression and head work, and the block was specially treated to make it stronger. It's got a ported slide carb with work done to it, fully blueprint and balanced engine, custom built crank, and too much money invested. It's a monster on race gas but I can't get this coil issue squared away.

When the coil starts going out, it will act like it wants to shut off under throttle. You crank the throttle and it sounds like you hit the kill switch and opened the throttle, just "baaaahhhhh"

It took a lot of research to do the motor the way I wanted, along with the help of a friend who is a Formula 1 engineer, and a rocket scientist when it comes to engines.

arc does make a pvl ignition for the hemi and that's good to 10,000 rpm's. my understanding most stock coils are good to only 8000+

what do I know...i'm just a gearhead.

well if your buddy is a rocket scientist, why hasn't he figured out the problem. hard to believe your engine is still making power over 10,500 rpms.

arc does make a pvl ignition for the hemi and that's good to 10,000 rpm's. my understanding most stock coils are good to only 8000+

what do I know...i'm just a gearhead.

arc does make a pvl ignition for the hemi and that's good to 10,000 rpm's. my understanding most stock coils are good to only 8000+

what do I know...i'm just a gearhead.

For starters I don't see a reason for the sarcasm...

The engine pulls power the whole way to the top of the rpm band, just cause your engine might die out around 8k doesn't mean mine does. It dies out right around 10,500 rpm. My buddy has nothing to do with the coil, as he doesn't make parts for lawn mower engines. It's not like he's gonna make a custom coil, so your comment it irrelevant. He's the one that said you're probably killing them with the RPM and the magnets used in the ARC Billet Flywheel. My question was if someone made one compatible with with the ARC Billet Flywheel. I noticed they have one for the PVL Flywheel but I'm not sure if it works for the Billet Flywheel. I need to contact the manufacturer, unless someone on here knows.

For starters I don't see a reason for the sarcasm...

The engine pulls power the whole way to the top of the rpm band, just cause your engine might die out around 8k doesn't mean mine does. It dies out right around 10,500 rpm. My buddy has nothing to do with the coil, as he doesn't make parts for lawn mower engines. It's not like he's gonna make a custom coil, so your comment it irrelevant. He's the one that said you're probably killing them with the RPM and the magnets used in the ARC Billet Flywheel. My question was if someone made one compatible with with the ARC Billet Flywheel. I noticed they have one for the PVL Flywheel but I'm not sure if it works for the Billet Flywheel. I need to contact the manufacturer, unless someone on here knows.

The engine pulls power the whole way to the top of the rpm band, just cause your engine might die out around 8k doesn't mean mine does. It dies out right around 10,500 rpm. My buddy has nothing to do with the coil, as he doesn't make parts for lawn mower engines. It's not like he's gonna make a custom coil, so your comment it irrelevant. He's the one that said you're probably killing them with the RPM and the magnets used in the ARC Billet Flywheel. My question was if someone made one compatible with with the ARC Billet Flywheel. I noticed they have one for the PVL Flywheel but I'm not sure if it works for the Billet Flywheel. I need to contact the manufacturer, unless someone on here knows.

For starters I don't see a reason for the sarcasm...

The engine pulls power the whole way to the top of the rpm band, just cause your engine might die out around 8k doesn't mean mine does. It dies out right around 10,500 rpm. My buddy has nothing to do with the coil, as he doesn't make parts for lawn mower engines. It's not like he's gonna make a custom coil, so your comment it irrelevant. He's the one that said you're probably killing them with the RPM and the magnets used in the ARC Billet Flywheel. My question was if someone made one compatible with with the ARC Billet Flywheel. I noticed they have one for the PVL Flywheel but I'm not sure if it works for the Billet Flywheel. I need to contact the manufacturer, unless someone on here knows.

The engine pulls power the whole way to the top of the rpm band, just cause your engine might die out around 8k doesn't mean mine does. It dies out right around 10,500 rpm. My buddy has nothing to do with the coil, as he doesn't make parts for lawn mower engines. It's not like he's gonna make a custom coil, so your comment it irrelevant. He's the one that said you're probably killing them with the RPM and the magnets used in the ARC Billet Flywheel. My question was if someone made one compatible with with the ARC Billet Flywheel. I noticed they have one for the PVL Flywheel but I'm not sure if it works for the Billet Flywheel. I need to contact the manufacturer, unless someone on here knows.