Massacre, refer to page 98 in the L head shop manual that you can reference from small engine suppliers (linked up in the sticky threads in this section...page 98 will actually be page 102 if viewed in the PDF). Use columns 3 (for the late model HS50 and HSSK engines) and 4 (early HS50 and HSSK engines) Maybe print that page out and highlight the numbers shown in the "Bore", "Piston diameter Bottom of skirt" and "piston skirt clearance" sections

Now go back and measure everything again that way and see where your at on the numbers? Also, you weren't simply experiencing a bind somewhere were you when you put it together the first time? I had a deformed rod throw me for a loop once, shit happens. Have you bolted the cylinder shroud onto that block?...If so, you didn't use too long of a bolt and accidentally poke into the cylinder bore or anything like that???

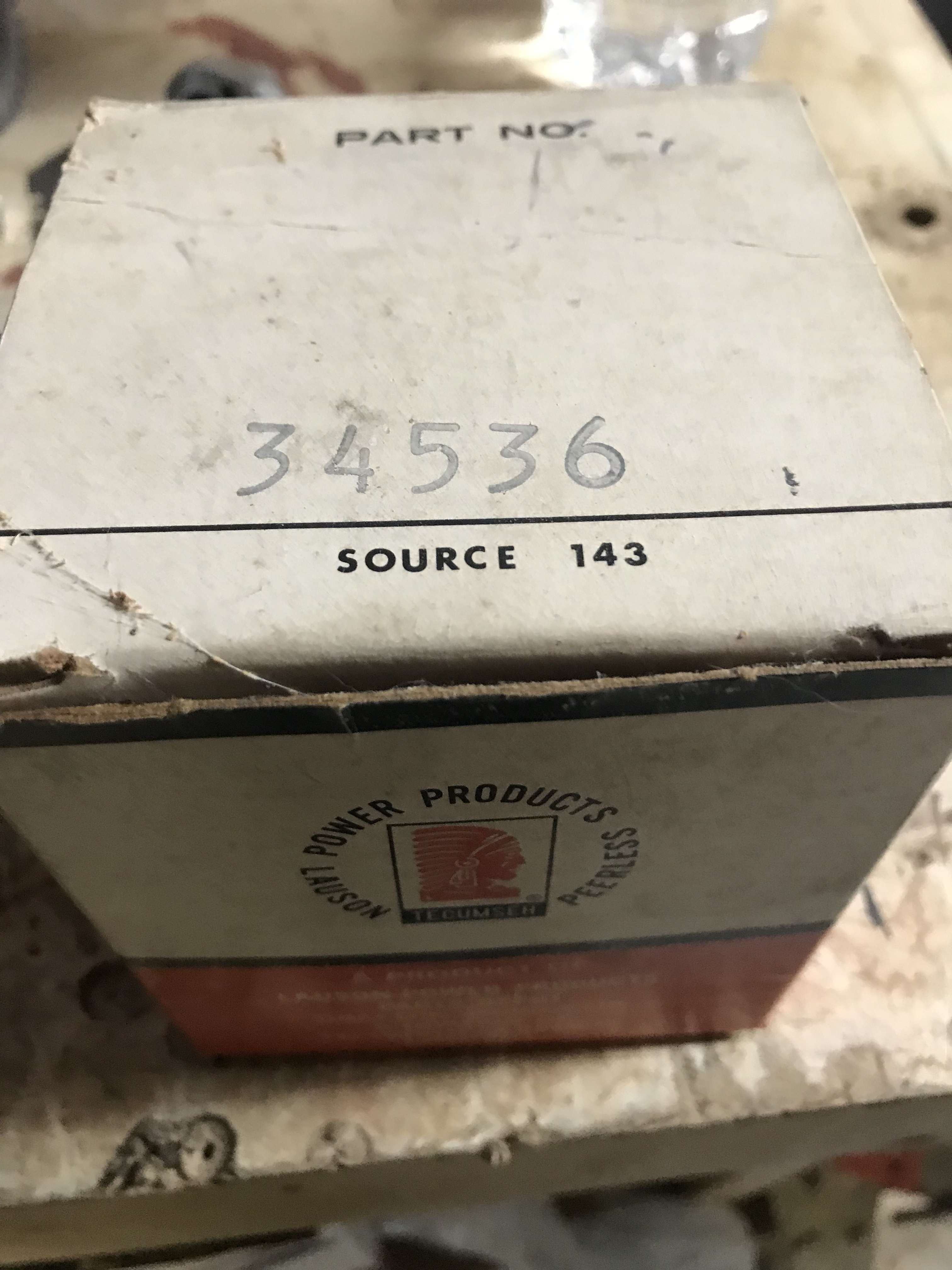

If you do in fact have a .010 over piston assembly, It should be clearly marked on the top of the piston as such, the rings if it came with them, could be a crapshoot though unless it was a factory sealed box or from a new parts vendor.

Now go back and measure everything again that way and see where your at on the numbers? Also, you weren't simply experiencing a bind somewhere were you when you put it together the first time? I had a deformed rod throw me for a loop once, shit happens. Have you bolted the cylinder shroud onto that block?...If so, you didn't use too long of a bolt and accidentally poke into the cylinder bore or anything like that???

If you do in fact have a .010 over piston assembly, It should be clearly marked on the top of the piston as such, the rings if it came with them, could be a crapshoot though unless it was a factory sealed box or from a new parts vendor.