ok guys i was planning on finishing my build off project for my nephew. things have change? he's just to big for a hardtail 3hp briggs and at almost 15yrs old and 140 or so pounds:doah:. he as been riding atv's and has over 35 acres of farm land and trails to ride on. so i think i will try to build him something that he can ride on farm path roads and trails. i pick up a large baja minibike couple years ago with out a motor for $100. couple things i would like to do to it . build a rear suspension and install a flathead 5hp briggs and a torque converter.

here are some mock-up pictures on how i would like it to look like.

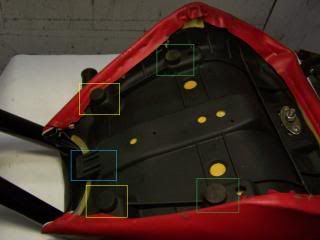

this part of the frame i will be cutting off for the rear springs:hack:

also on the engine mount there is a small plate in the rear that will need to cut off:hack:

to make a rear suspension out of the original frame i will need to cut a small peice out of the lower frame behind the engine mount and install some bushings and then become a lower swing arm.

engine i am using is just for mock-up only. i have another low hours snow blower 5hp briggs that i will be using and is ready to go:thumbsup:

the only thing i will have to do to make the engine fit good is to slot the engine mount holes 1/4 inch forward so the rear gas tank won't be so close to the frame rail.

.................:weld::grind::hack:

.................:weld::grind::hack:

here are some mock-up pictures on how i would like it to look like.

this part of the frame i will be cutting off for the rear springs:hack:

also on the engine mount there is a small plate in the rear that will need to cut off:hack:

to make a rear suspension out of the original frame i will need to cut a small peice out of the lower frame behind the engine mount and install some bushings and then become a lower swing arm.

engine i am using is just for mock-up only. i have another low hours snow blower 5hp briggs that i will be using and is ready to go:thumbsup:

the only thing i will have to do to make the engine fit good is to slot the engine mount holes 1/4 inch forward so the rear gas tank won't be so close to the frame rail.

.................:weld::grind::hack:

.................:weld::grind::hack: