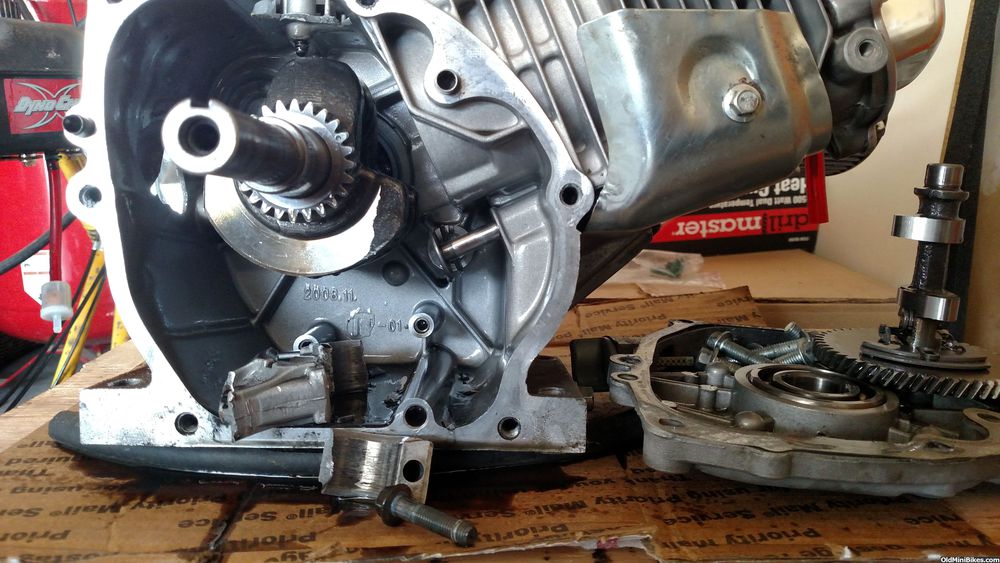

From the picture of what's left of the rod, it looks like it did get way over heated on the crank journal. Look at the surface of the rod & galling from the heat.

When this happens, the gap closes up from the higher heat, the rpm's can't keep enough oil in place with the stock rod dipper design. It gets too tight, oil is starved completely out of the space it usually goes (15 thousandths, or whatever the factory managed that day, becomes "0" or minus numbers in a very short amount of time), the heat continues to build until the turning creates enough friction to try to weld the rod in place on the crank. Since there's all that shit turning so fast without any oil, something breaks.

Parts, dollar signs & a new learning experience is created!