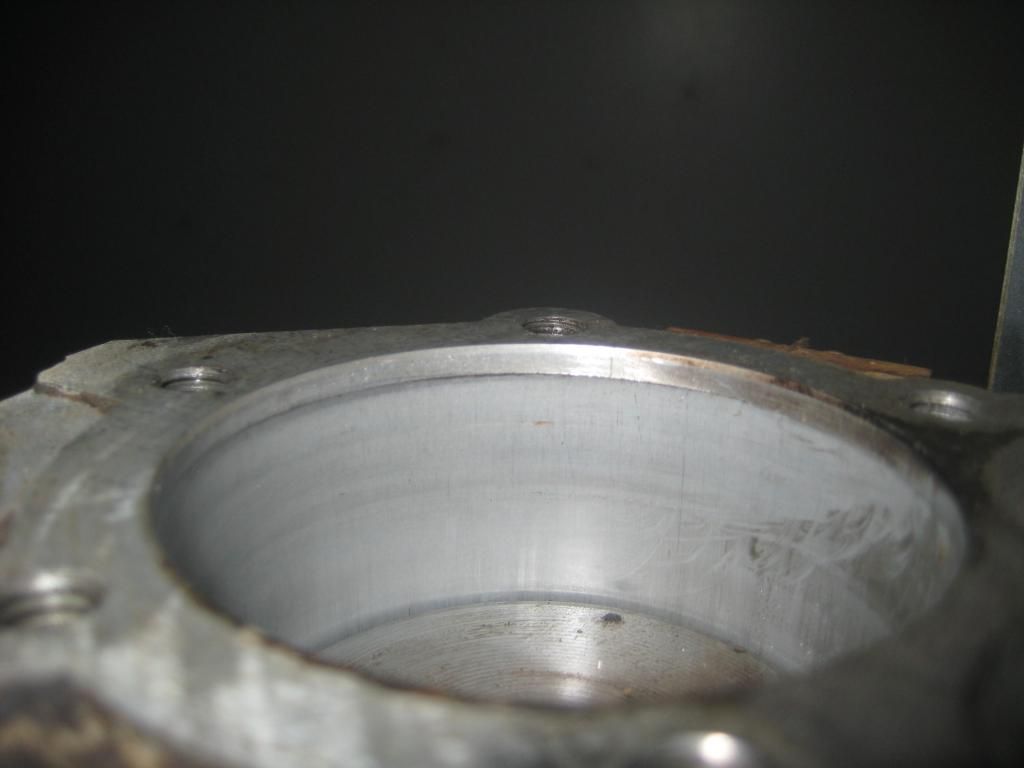

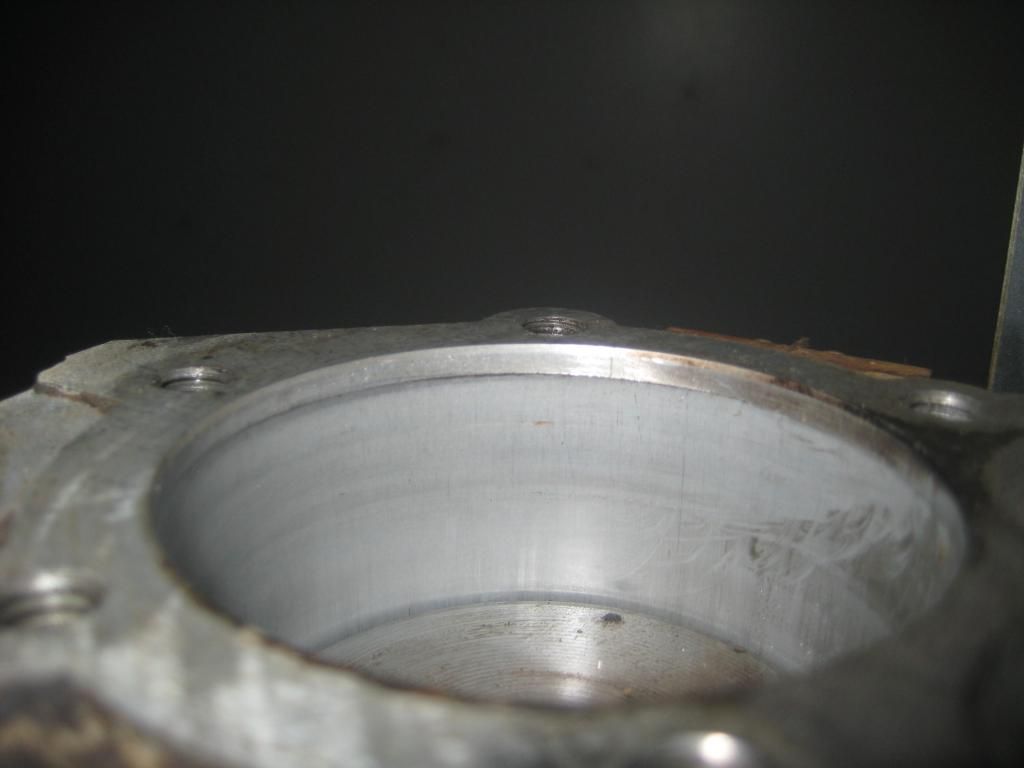

my friend gave me his older 5hp motor because it was smoking and oil was fouling the plug and the motor would shut off.. i pulled the whole thing apart and when i went to take the piston out, i couldn't.. there is a very small lip at the top of the cylinder that doesn't allow the rings to pass.. the lip only goes around half way.. i can remove the crank and pull it out through the bottom but would rather address the issue at the top of the cylinder.. i'm guessing the rings wore the cylinder down.. what's my next step?? not looking to dump money into it, just trying to get a few rides out of it.. maybe thicker rings, but what size??