High Performance Mods for my 1.75hp flathead Briggs

- Thread starter Minimichael

- Start date

what is the taper of the cylinder? i would measure it at two spots 90 degrees apart top, midway, and, bottom. nice job! use a soluble coolant on your final cuts.

The standard bore was 2.3125" (ie: 2 5/16"). And right now the top and middle are about 2.3215" -- while the bottom is still around 2.3210.

I may be fussing too much about a totally uniform +0.010" -- top to bottom. I do realize 5/16 is .3125", but aiming for an exact oversizing means chasing a half thousandth of an inch (ie: to 2.3225").

So I'll probably bury the difference and just go large on that last half thousandth -- to 2.323". I'm afraid to go narrow for fear the new piston wouldn't have enough clearance.

Thanks for the coolant tip. You mean like honing oil? I had mixed my own cutting oil last night after running out of WD-40. (3-in-1 oil and mineral spirits).

Last edited:

you don't want a taper but its good to make sure you dont have one that is significant. yours sounds fine. if your hone job is within a few thousandths you will be fine. a person much wiser than myself once said "people should need to get a license to get a micrometer or caliper that measures tenths!"

you don't want a taper but its good to make sure you dont have one that is significant. yours sounds fine. if your hone job is within a few thousandths you will be fine. a person much wiser than myself once said "people should need to get a license to get a micrometer or caliper that measures tenths!"

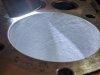

The cylinder is perfect.

I still had to take off a thou from the bottom, and half a thou from mid and top, and this "Glaze Breaker" hone just made easy work of it.

I oiled up and weighted down the block under the spindle just like the day before... Spun up the drill press to give those heavier spots a little extra attention and feathering... Stopped twice to measure, and I was done.

Now I'm dialed in at half a thou over plus ten just about everywhere, and I couldn't be happier.

I saved the hand drilling for the ball hone and just about 5 to 7 strokes gave me such great hash marks I think even the block enjoyed it See pics...

See pics...

I still had to take off a thou from the bottom, and half a thou from mid and top, and this "Glaze Breaker" hone just made easy work of it.

I oiled up and weighted down the block under the spindle just like the day before... Spun up the drill press to give those heavier spots a little extra attention and feathering... Stopped twice to measure, and I was done.

Now I'm dialed in at half a thou over plus ten just about everywhere, and I couldn't be happier.

I saved the hand drilling for the ball hone and just about 5 to 7 strokes gave me such great hash marks I think even the block enjoyed it

Attachments

-

3.1 MB Views: 29

-

2.1 MB Views: 28

-

3.2 MB Views: 21

-

3 MB Views: 17

Last edited:

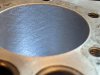

After days of honing with stones and ball hone and batches of homemade honing oil, a good washing is important this time and I want to make sure not to leave any grit behind -- like stuck within the fresh crosshatching. Next time I'll try a soluble cutting fluid to reduce the chance of this.

Thanks Phil1958 for the soluble advice

Thanks Phil1958 for the soluble advice

Attachments

-

3.5 MB Views: 7

Last edited:

I'm measuring for clearance between the valves and the head, before shaving or even leveling any head or deck material...

Valve lift requirements

Valve face above deck:

1.05mm

Cam lobes, open minus closed:

23mm - 19mm = 4mm

Thus, total valve rise:

4mm + 1.05mm = 5.05mm*

*(Disregarding valve lash)

Head ceiling height

Head ceiling above gasket face:

5.7mm

Copper head gasket**:

1.15mm

Thus, total head ceiling height:

5.7mm + 1.15mm = 6.85mm

Therefore, head/gasket height from deck is 6.85mm, minus valve rise of 5.05mm = 1.8mm clearance

**Note the OEM gasket measures 1.75mm. This means installing the copper head gasket (which is thinner, at only 1.15mm) is equivalent to having already shaved 0.6mm (or, 0.0394") from the stock head.

And because 40 thousandths ain't no chump change, I'll figure out compression next.

Once I have the piston installed...

Valve lift requirements

Valve face above deck:

1.05mm

Cam lobes, open minus closed:

23mm - 19mm = 4mm

Thus, total valve rise:

4mm + 1.05mm = 5.05mm*

*(Disregarding valve lash)

Head ceiling height

Head ceiling above gasket face:

5.7mm

Copper head gasket**:

1.15mm

Thus, total head ceiling height:

5.7mm + 1.15mm = 6.85mm

Therefore, head/gasket height from deck is 6.85mm, minus valve rise of 5.05mm = 1.8mm clearance

**Note the OEM gasket measures 1.75mm. This means installing the copper head gasket (which is thinner, at only 1.15mm) is equivalent to having already shaved 0.6mm (or, 0.0394") from the stock head.

And because 40 thousandths ain't no chump change, I'll figure out compression next.

Once I have the piston installed...

Attachments

-

1.1 MB Views: 10

-

904.8 KB Views: 11

-

2.4 MB Views: 10

-

827.1 KB Views: 11

-

2.8 MB Views: 10

-

2.2 MB Views: 10

-

1.4 MB Views: 10

-

1.2 MB Views: 8

Last edited:

Call me crazy but today I did some valve grinding with a hand file. Not to grind the actual seating surface but just to try and clean up some boogery dents and bumps along the intake valve's upper edge ...since it was pretty clear it had met with something like channel locks in the past. I didn't want those dents to interfere with my valve lapping, or with normal wear. (I try to show in the early pics just how much material is displaced by the dents - potentially deforming the face). Anyway, with a small file and the drill press on slow, and as steady a hand as I could muster, I was able to take that material down to a more uniform level, and still just above the existing level of wear. So, I'm happy enough with these results that I won't be buying those nos valves on eBay just yet. Also that wear indent in the valve face is very slight and at it's worst only on this valve anyway. Otherwise, all the lap and seat lines are a smooth and even 3/32" so I don't even expect to do much lapping.

So I just wanted peace of mind about the dents and bumps not disrupting the intake's flow or wear or fit or whatever. This is supposed to be a high performance build after all ;-)

So I just wanted peace of mind about the dents and bumps not disrupting the intake's flow or wear or fit or whatever. This is supposed to be a high performance build after all ;-)

Last edited:

Looks like those valves have a lot of room for a back cut and polishing.

Maybe if you're using a boring head and trying to figure out how much cutter adjustment will affect the diameter, but that's not the case here. Taking 0.010" off the inside diameter will increase the diameter by 0.010". You can't dial a flex a hone to some preset size.

Remember, if you remove 0.010" of material, that will make the cylinder 0.020" oversize.

You only want to remove 0.005".

You only want to remove 0.005".

Looks like those valves have a lot of room for a back cut and polishing.

Maybe if you're using a boring head and trying to figure out how much cutter adjustment will affect the diameter, but that's not the case here. Taking 0.010" off the inside diameter will increase the diameter by 0.010". You can't dial a flex a hone to some preset size.

Maybe if you're using a boring head and trying to figure out how much cutter adjustment will affect the diameter, but that's not the case here. Taking 0.010" off the inside diameter will increase the diameter by 0.010". You can't dial a flex a hone to some preset size.

I've been looking for this tool, I bought 1 but it was for larger valves, You clamp the tool in a vise. Stines? used to sell one for small engines...

Goodson sells a hand crank ring gap cutter. It can also trim valve stems: https://goodson.com/products/prf-250-piston-ring-filer

& Neway makes a seat cutter kit, but they are pricy. I still have my Grandfathers one. they also make cutters for valve faces:

Goodson sells a hand crank ring gap cutter. It can also trim valve stems: https://goodson.com/products/prf-250-piston-ring-filer

& Neway makes a seat cutter kit, but they are pricy. I still have my Grandfathers one. they also make cutters for valve faces:

These are good tips. Thanks. I too have a neway seat cutter kit, so perhaps I'll look into the valve cutter pricing. Since you included the pic I assume you've used them? How'd they work?

The hand crank would be cool. Maybe you mean Stens?

The hand crank would be cool. Maybe you mean Stens?

May be an option for you

I just grabbed the pics off google, but I imagine It would be similar to the Neway seat cutter except on the inverse. Have a bit of a light touch or it will get jammed in a certain spot if it cuts too deep & its a bit tricky to cut through the sticky spot until its smooth again. The vise clamp jig I once had, they sent an old valve with it out of a 350 or something & it was really easy to use "like a pencil sharpener" Mine was different then the picture shown & had a hardened cutter like a large piece of square key stock that went in a corresponding square hole so it could be adjusted it diagonally in or out & locked with a thumb screw. But it wouldn't reach a small valve, the cutter wasn't long enough or the hole close enough for the smaller diameter. Just wanted to point out if it wasn't obvious to you already, All the other ring end cutter tools don't have a channel milled in them to accept a valve stem, but they are around 3 times cheaper. Mine works well, I screw it to my workbench to use but you have to use firm pressure with your thumb to keep the valve secure while cutting & this can get repetitive & tiering but beats sticking the valve in the block & using folded up fine sandpaper or a needle file between the tappet & stem to adjust, this method is excruciating...