I have bored a late model HSSK50 motor (with smaller bore and thin ring piston) to use an old school HS50 thick ring piston. It actually works quite well. The HSSK50 motor was really worn, needed .020 over. Guess what... a stock thick ring HS50 piston is .020 over a new style thin ring piston! So it's like you found an endless supply of .020 over pistons...

tecumseh 2-13/16 bore piston

- Thread starter anthonyg

- Start date

delray. i reread your hs40 build in its entirety. had a buddy with harley 45 cubic inch flat head took the babbit bearings out put timken roller bearings in it. this is back in 1981 we were all amazed. your needle bearing on the mag side is skilled and artful work. undercutting the valve stems at the top (tuelliping) is reserved for hight end race engines and your idea for welding the flats in the back of the bowl outside the case is excellent. i wonder if you can fit the torch - -scratch that idea i just looked at the block. I'm a welder. i don't think you can fit even a small handle tig torch in there. your bowl porting is spot on. don't mirror polish the intake side. a ruff surface will atomize the fuel a lot better. by the looks of it i think the intake port on these require a lot more cleanup than the exhaust. but you'd no better than me. i would like to relieve the block (shave the block from just past the valve seat to the bore) but there is almost zero room. i know is not really needed but its the cool factor. i can see this is not your fist time around the block building these engines. far from it. looking at your machine work like markus paint and attention to detail is gonna make me strive for for perfection. thats a real nice hs40 build. i hope mine turns out half as nice.i will keep you posted. anthony.

delray. i looked at the picture of the block made in italy. unusual desirable and completely impossible to get. how in the hell did you find not one but two of these things and how many people tried to buy the from you. what are they 40s 50s or h35s? i called the shop that advertised the new block. i gave the guy the part number off there web page with there part number and price. $ 87.00. the guy tells me thats the part number for an oil dipstick. asks for the hs50 model code. and said let me check the computer. at that point i knew i was screwed. answer that part is no longer available. i wanted to say clean up you f#*:"EN web site. lost sleep last nigh thinking about a brand new 47 year old block. time to rethink my options. trying to find parts to build one of these is like a rollercoaster ride. very disappointing. time to regroup and smoke a cigaret. anthony.

that would be really cool to here that Harley engine turn some rpm's.

yes for those flatspots in the back they do look hard to get too. I kind wonder if a guy can't get to them with a welder what other options do you have? i do remember ready on some special epoxy engine builders use in heads in the past and it wasn't JB weld either,maybe something look into?

also wonder how much air flow you get on the back side of the bowl area(flat spots) i see you caught the part with the thinner rings...

most people don't really get it with the thinner rings,but then again no one here is really turning there re-ring motors at 7000+ rpm's

most people don't really get it with the thinner rings,but then again no one here is really turning there re-ring motors at 7000+ rpm's

thats to bad on the block,but really not the end of the world. you still have some options if you really want to build a bad ass motor and don't mine going though some extra steps to make it happen. I will be talking about this subject up under my OHH BUILD.

https://www.oldminibikes.com/forum/index.php?threads/tecumseh-ohh-build.131688/page-6

something you and the 6 other guys that are into the Tecumseh hot rodding to think about. the ohh block is pretty much a hs-50 design. uses the same cam,crank,rod.piston..etc all in round about way and what I am doing to it you could do this to a flathead. which I will in the future.

yes for those flatspots in the back they do look hard to get too. I kind wonder if a guy can't get to them with a welder what other options do you have? i do remember ready on some special epoxy engine builders use in heads in the past and it wasn't JB weld either,maybe something look into?

also wonder how much air flow you get on the back side of the bowl area(flat spots) i see you caught the part with the thinner rings...

thats to bad on the block,but really not the end of the world. you still have some options if you really want to build a bad ass motor and don't mine going though some extra steps to make it happen. I will be talking about this subject up under my OHH BUILD.

https://www.oldminibikes.com/forum/index.php?threads/tecumseh-ohh-build.131688/page-6

something you and the 6 other guys that are into the Tecumseh hot rodding to think about. the ohh block is pretty much a hs-50 design. uses the same cam,crank,rod.piston..etc all in round about way and what I am doing to it you could do this to a flathead. which I will in the future.

If you absolutely have to have a new block, Floyds has been sitting on an SBH for a long time. Its small bore cylinder (thin ring piston) with large valves. Its not a recreational spec setup so its bushing shaft and worse yet top fill oil hole sidecover, but it is non PTO cam at least. While its the early 90's block it is in fact the replacement for the pre 1981 points engines so it is a small taper crankshaft, so don't let the external coil lugs throw you off they just updated parts as they went along so people could still fix their old engines.

ebay item number 332578013157

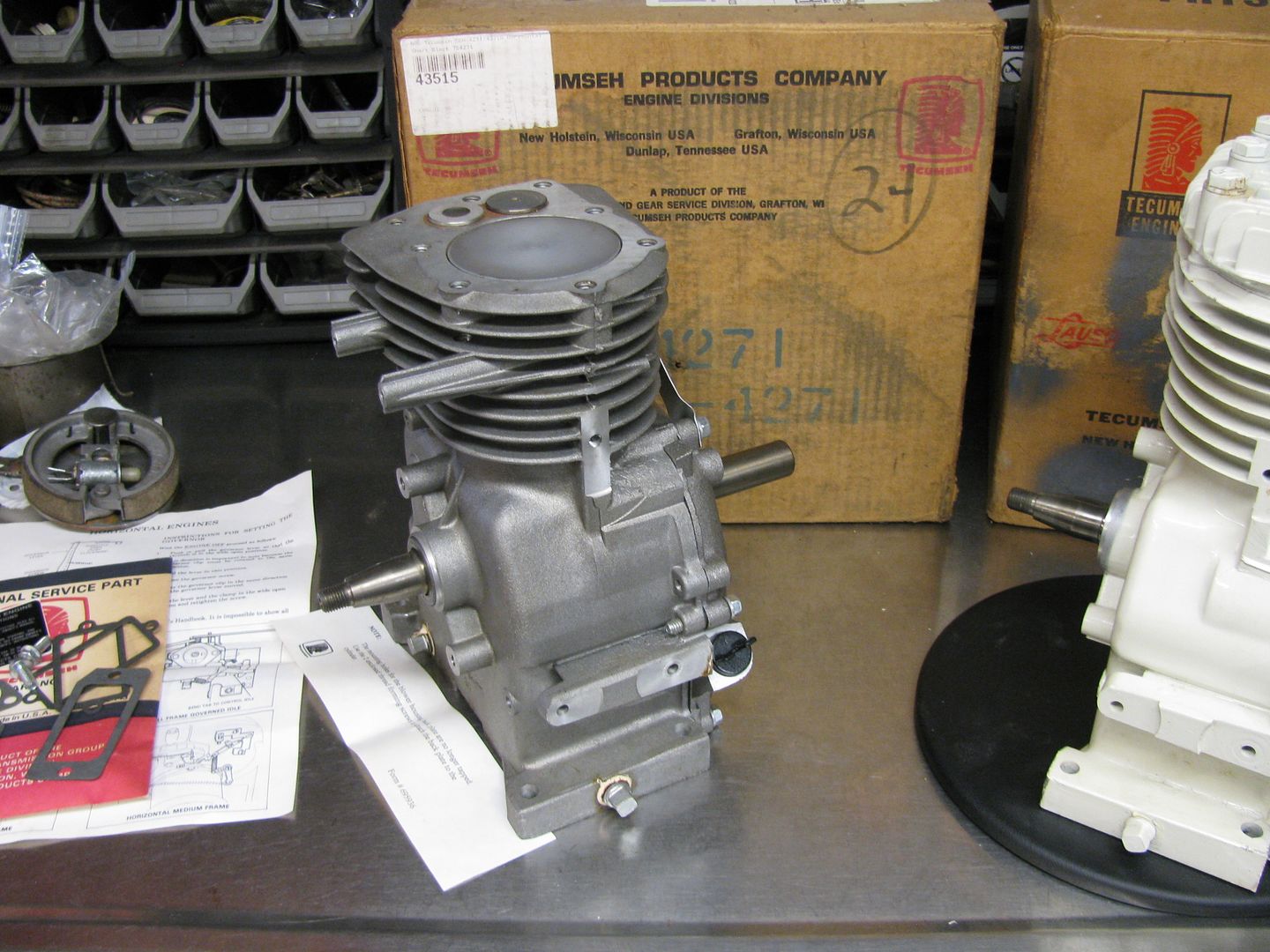

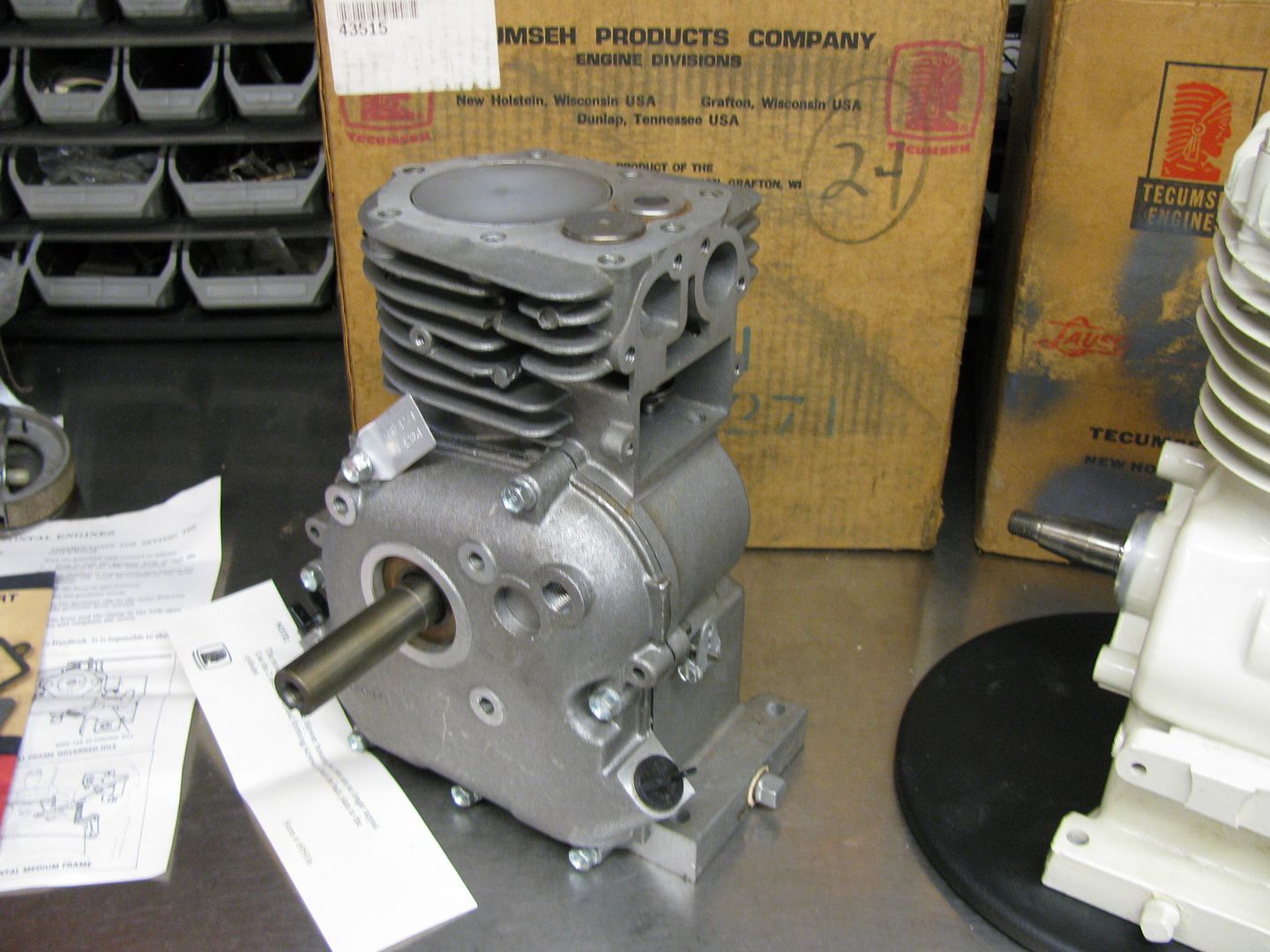

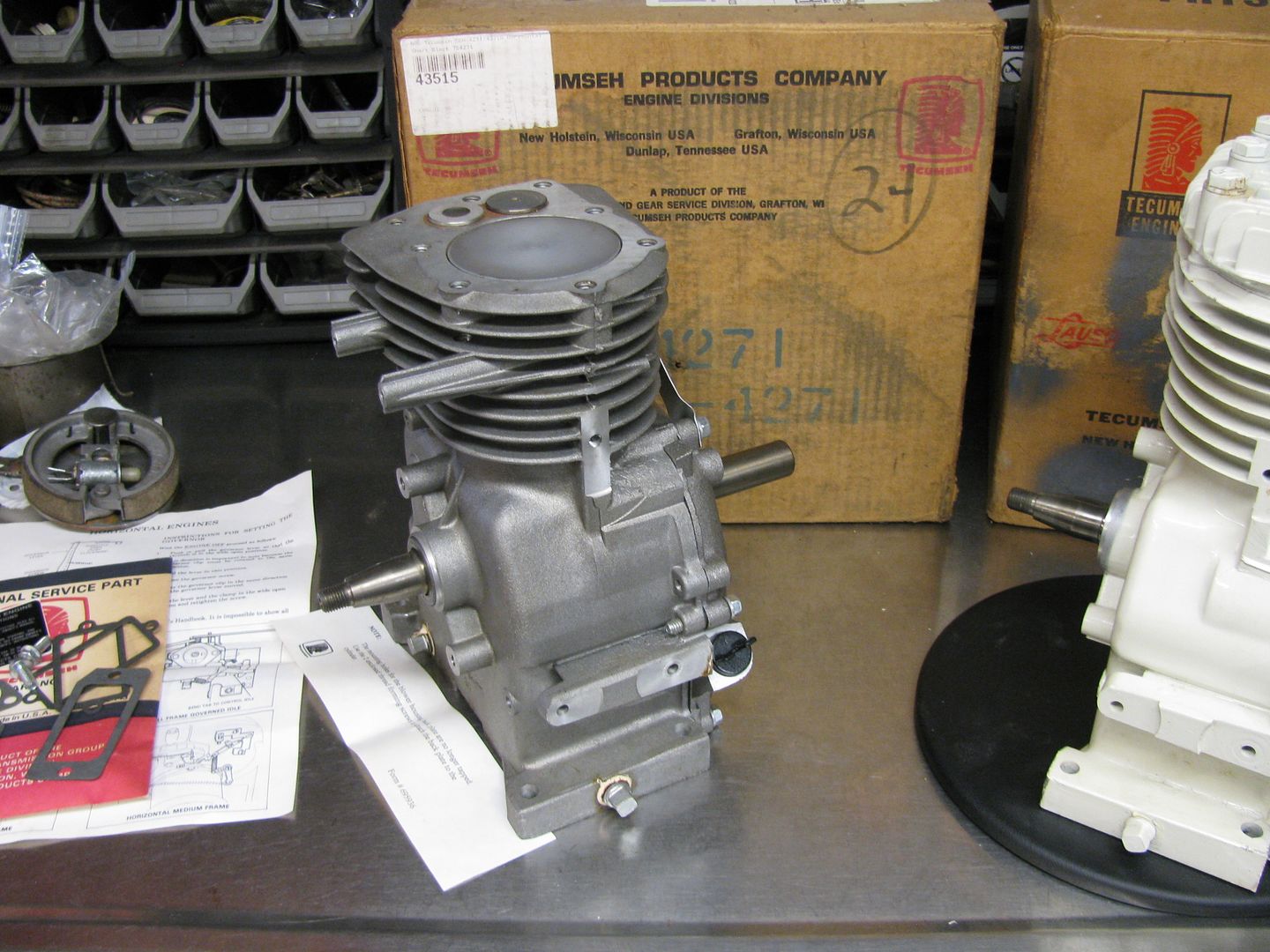

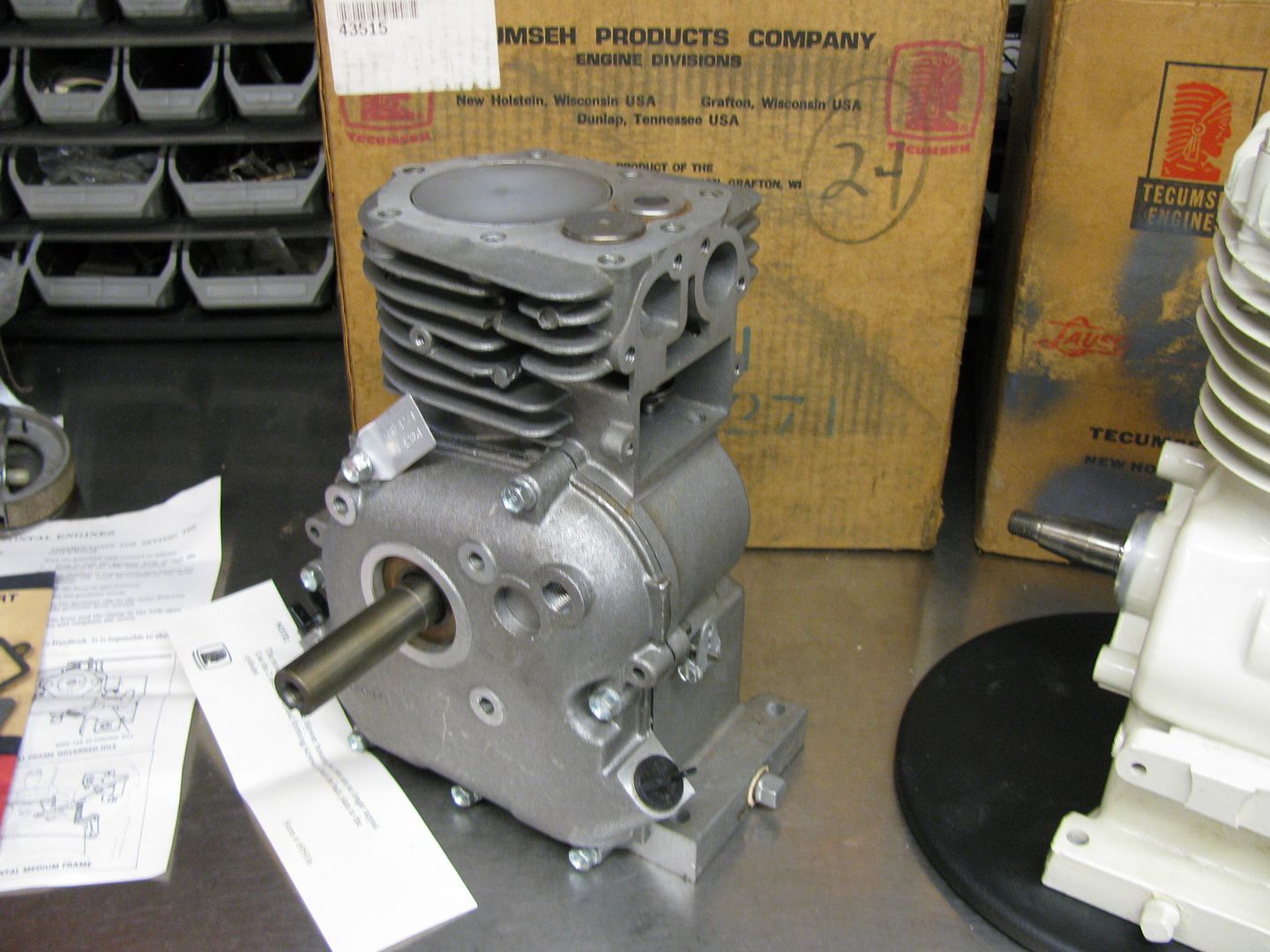

I got the last "recreational spec" version they had while back. It was of the same era, so its the later block ( smaller piston/thin ring with big ex valve but with a small taper ball bearing crankshaft ) seen here:

) seen here:

cant stress this enough though, treat an SBH (no matter the year or era) as you would a new build from scratch. Tear it all down, clean, clean, clean, measure etc.. I did a throw together from an SBH from the mid 2000's that you could buy for $50 last year on ebay (the ones people were buying and flipping them out for $100-200 on here in the last year). out of the box it puffed a wiff of smoke off idle. It was my stupidity, I needed a runner fast to do some testing on something I came up with, I felt it was new enough and sealed in the box still that it would not be an issue, it was. So I had to tear it down, hone and put new rings in it.....Actually I stole the rings from the engine above since I didn't have a set of thin rings in stock at the time and that fixed the problem. Being lazy doesn't pay off!

and that fixed the problem. Being lazy doesn't pay off!

ebay item number 332578013157

I got the last "recreational spec" version they had while back. It was of the same era, so its the later block ( smaller piston/thin ring with big ex valve but with a small taper ball bearing crankshaft

cant stress this enough though, treat an SBH (no matter the year or era) as you would a new build from scratch. Tear it all down, clean, clean, clean, measure etc.. I did a throw together from an SBH from the mid 2000's that you could buy for $50 last year on ebay (the ones people were buying and flipping them out for $100-200 on here in the last year). out of the box it puffed a wiff of smoke off idle. It was my stupidity, I needed a runner fast to do some testing on something I came up with, I felt it was new enough and sealed in the box still that it would not be an issue, it was. So I had to tear it down, hone and put new rings in it.....Actually I stole the rings from the engine above since I didn't have a set of thin rings in stock at the time

markus. read what you said carefully. i don't mind the small bore. i like the thin ring piston. but the non ballbearing part is not an option for me. today i ripped the engine down completely. i left the piston in and measured the bottom skirt to wall clearance. a 0.006 feeler slipped in nice and snug. i divide that in two. 0.003 per side . spec chart set 0.002 to 0.004 is acceptable. am i correct? the 0.020 over bore is dead on spec. the piston is correct. if i manage to hand ream the block correctly. i will make dew with this block. when i moved to my smaller house i gave away several hs40 and 50 blocks cranks flywheels blower covers the the whole nine yards. big mistake. and the plot thickens. thanks for the input. anthony.

that would be really cool to here that Harley engine turn some rpm's.

yes for those flatspots in the back they do look hard to get too. I kind wonder if a guy can't get to them with a welder what other options do you have? i do remember ready on some special epoxy engine builders use in heads in the past and it wasn't JB weld either,maybe something look into?

also wonder how much air flow you get on the back side of the bowl area(flat spots) i see you caught the part with the thinner rings...

most people don't really get it with the thinner rings,but then again no one here is really turning there re-ring motors at 7000+ rpm's

most people don't really get it with the thinner rings,but then again no one here is really turning there re-ring motors at 7000+ rpm's

thats to bad on the block,but really not the end of the world. you still have some options if you really want to build a bad ass motor and don't mine going though some extra steps to make it happen. I will be talking about this subject up under my OHH BUILD.

https://www.oldminibikes.com/forum/index.php?threads/tecumseh-ohh-build.131688/page-6

something you and the 6 other guys that are into the Tecumseh hot rodding to think about. the ohh block is pretty much a hs-50 design. uses the same cam,crank,rod.piston..etc all in round about way and what I am doing to it you could do this to a flathead. which I will in the future.

yes for those flatspots in the back they do look hard to get too. I kind wonder if a guy can't get to them with a welder what other options do you have? i do remember ready on some special epoxy engine builders use in heads in the past and it wasn't JB weld either,maybe something look into?

also wonder how much air flow you get on the back side of the bowl area(flat spots) i see you caught the part with the thinner rings...

thats to bad on the block,but really not the end of the world. you still have some options if you really want to build a bad ass motor and don't mine going though some extra steps to make it happen. I will be talking about this subject up under my OHH BUILD.

https://www.oldminibikes.com/forum/index.php?threads/tecumseh-ohh-build.131688/page-6

something you and the 6 other guys that are into the Tecumseh hot rodding to think about. the ohh block is pretty much a hs-50 design. uses the same cam,crank,rod.piston..etc all in round about way and what I am doing to it you could do this to a flathead. which I will in the future.

markus. read what you said carefully. i don't mind the small bore. i like the thin ring piston. but the non ballbearing part is not an option for me. today i ripped the engine down completely. i left the piston in and measured the bottom skirt to wall clearance. a 0.006 feeler slipped in nice and snug. i divide that in two. 0.003 per side . spec chart set 0.002 to 0.004 is acceptable. am i correct? the 0.020 over bore is dead on spec. the piston is correct. if i manage to hand ream the block correctly. i will make dew with this block. when i moved to my smaller house i gave away several hs40 and 50 blocks cranks flywheels blower covers the the whole nine yards. big mistake. and the plot thickens. thanks for the input. anthony.

markus. when i came across that block it was purely accidental. and for $87.00 it was a no brainer. i should have known the blocks were long gone. got i little to excited.and not being realistic on the time frame of a build. until i found this forum i had no reference point of what could be achieved with my little hs50. if there is a way to get a small ring piston in this thing i want to do it. maybe there is i slightly larger piston for one of the ohh motors with the same size wrist pin and pin to deck hight. delray is messing around with one of the newer motors. i have a feeling he might have an answer for this. it seems like the more i lean the more i expect. and i met the right guys on this forum to make it happen. yourself included, thanks for your patience. anthony.