Hs-40 build

- Thread starter delray

- Start date

not sure with the 2 strokes. there has to be some kind of treatment to the bearing surface for the rollers. on my type of crank it's just a cast steel crank and cast vs harden rollers isn't good.

I would like to maybe try angle the valves on a future hs-50 build and sink the valves little and channel(block/deck) it out to the piston. but then your talking about machining the piston down ,milling the head so you could try getting some of your compression back. there would be a lot of dinking around just to find out there was no ganes……...:doah: never know until you try...:shrug:

.

.

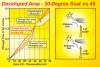

Less of a turn for the airflow.

Push the piston and roof up and the air has less turning to do?

Essentially similar to sinking and trenching valves

Last edited:

here is another little crazy part I desided to do with the valves. I purchase set of briggs narrow stem SS valves and cut them down to size.

first thing was to cut down the top to the correct size.

and then the end of the stems.

and then make a new groove for the locks.

and then grind a new face on my old hall valve refacer

https://www.oldminibikes.com/forum/shop-tools/155643-valve-grinder.html

then use my new neway cutting set to give me a 3 angle valve job.

if I wanted I could of made the stock briggs valves work. the intake was a 1.125 and the exhaust 1.00

I never double check to see if the intake would clear the side of the chamber head. it would of been very close if not hitting it? now on a hs-50 I believe would be just little bigger and that just might work on that motor. either way on the Tecumseh valves in my opinion they are plenty big enough.

first thing was to cut down the top to the correct size.

and then the end of the stems.

and then make a new groove for the locks.

and then grind a new face on my old hall valve refacer

https://www.oldminibikes.com/forum/shop-tools/155643-valve-grinder.html

then use my new neway cutting set to give me a 3 angle valve job.

if I wanted I could of made the stock briggs valves work. the intake was a 1.125 and the exhaust 1.00

I never double check to see if the intake would clear the side of the chamber head. it would of been very close if not hitting it? now on a hs-50 I believe would be just little bigger and that just might work on that motor. either way on the Tecumseh valves in my opinion they are plenty big enough.

FirePowerMinis

actually that picture is little misleading firepowermini, they where still the 1.125 int and 1.00 ex and the long stems before cut down.

nice thing with using the over size valves it did allow me to cut down some material to the actual size and I did take little extra material off the narrow stem area and didn't have worry about compromise integrity of the valve for my application. something that you really can't do on a stock valve because way they are made of two pieces that are fused/welded together.

What I meant was, there's a lot of extra weight left on those. You can make the margin pretty small, just short of sharp, and radius it.

Then a 30 degree back cut takes a bunch off the tulip.

Then a 30 degree back cut takes a bunch off the tulip.

nice thing with using the over size valves it did allow me to cut down some material to the actual size and I did take little extra material off the narrow stem area and didn't have worry about compromise integrity of the valve for my application. something that you really can't do on a stock valve because way they are made of two pieces that are fused/welded together.

.

Or,,, leave the valves high, and pop the piston up out of the hole in to a relieved head, with a little chamfer on the valve side?

Less of a turn for the airflow.

Push the piston and roof up and the air has less turning to do?

Essentially similar to sinking and trenching valves

Or,,, leave the valves high, and pop the piston up out of the hole in to a relieved head, with a little chamfer on the valve side?

Less of a turn for the airflow.

Push the piston and roof up and the air has less turning to do?

Essentially similar to sinking and trenching valves

so way back in the day wiseco engineers may have been thinking the samething. but Tecumseh engineers where thinking the other direction?

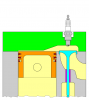

here is the piston popping up .020

FWIW, I was just talking to a Tec racing legend, and he agreed the crank is way too soft for a direct roller race.

Last edited:

I needed to make a jeg that would hold the cam square with my mill and I could repeat the whole process if needed to for another future build engine. this chunk aluminum seem to work out good.

first thing was to machine a area for the cam.

I first initially bored a small hole to make sure the cam gear fit correct.

then went back and bored it so the cam lobes would fit inside the jeg.

I tried couple different cams to see how it fit...….all good:thumbsup:

next step was to machine a groove area to hold it down on the milling table.

first thing was to machine a area for the cam.

I first initially bored a small hole to make sure the cam gear fit correct.

then went back and bored it so the cam lobes would fit inside the jeg.

I tried couple different cams to see how it fit...….all good:thumbsup:

next step was to machine a groove area to hold it down on the milling table.

Lookin' good :thumbsup: Do you know if the 37670 lifter/tappets will plug and play with the larger lobes on the MCR camshafts in the HS engines? I bought a 33158 camshaft to try out, steel MCR, but its out of an OHH. They get kinda confusing with part numbers, the steel MCR's that were listed for the very late 5.5 L heads were different numbers. Thinking the MCR's got bigger lobes across the board though to clear the bump shaft on the flyweight hence a change to shorter lifters from the ones in the older HS engines. If thats the case that might make for an at least easier fit of the Dyno and Tecumseh racing camshafts into the HS engines

I got the camshaft but forgot the thrust washer keeper....converting over to the steel MCR into a stcok HS is gonna nickle and dime me to death :doah:

I got the camshaft but forgot the thrust washer keeper....converting over to the steel MCR into a stcok HS is gonna nickle and dime me to death :doah:

yes markus 37670 lifter appears to be for the newer compression relief cams. that number comes up for the LH 195 and the HSSK 55.

195 is basically the ohh motor and the HSSK 55 is the newer/last of the flatthead motors. I believe all of them should have the compression relief.

one way to makesure what cam you have in front of you would be to measure it with a mic or calipers.

the compression relief cam will mic out at about + or - .857

and the old cam about +or- .784

the other number you gave me is little confusing.

massacre,one reason why I like the newer compression relief setup it allows you the advance timing and not worry about ripping your hand off and setup correct you can gain little more extra power.

guys decide to go with just the newer stock cam with the compression relief it works very good with the bowls ported ,timing advance,header, and a 19mm dellorto with adjustable jet. kind that are off a black widow bike.

but caution when installing a newer cam with this compression relief setup. you must use the thrust washer that comes with the cam and there will be a small part inside the pto cover where the cam rides that needs to be modified. I will be posting more info on this with my hs-40 build....:thumbsup:

195 is basically the ohh motor and the HSSK 55 is the newer/last of the flatthead motors. I believe all of them should have the compression relief.

one way to makesure what cam you have in front of you would be to measure it with a mic or calipers.

the compression relief cam will mic out at about + or - .857

and the old cam about +or- .784

the other number you gave me is little confusing.

massacre,one reason why I like the newer compression relief setup it allows you the advance timing and not worry about ripping your hand off and setup correct you can gain little more extra power.

guys decide to go with just the newer stock cam with the compression relief it works very good with the bowls ported ,timing advance,header, and a 19mm dellorto with adjustable jet. kind that are off a black widow bike.

but caution when installing a newer cam with this compression relief setup. you must use the thrust washer that comes with the cam and there will be a small part inside the pto cover where the cam rides that needs to be modified. I will be posting more info on this with my hs-40 build....:thumbsup:

Last edited:

need to drill and tap couple holes on the top sides/edge.

this will be to hold the the cam down in place for more machine of the compression relief.

I milled little half moon cut out . also note I made couple threaded pins. one right on the timing mark and the other straight across from that.

center drilled a hole.

drilled the hole away though.

here is what it looks like on the back side.

cam lever down

cam lever up..:thumbsup:

this cam does have the smaller center lobes like the vintage cams did. so by making this jeg it allow me to setup a newer stock compression relief cam in my jeg and center everything up. then base on the measurements I got it allow me to find the area I needed to machine out on my dyno cam.

cam lever installed.

this will be to hold the the cam down in place for more machine of the compression relief.

I milled little half moon cut out . also note I made couple threaded pins. one right on the timing mark and the other straight across from that.

center drilled a hole.

drilled the hole away though.

here is what it looks like on the back side.

cam lever down

cam lever up..:thumbsup:

this cam does have the smaller center lobes like the vintage cams did. so by making this jeg it allow me to setup a newer stock compression relief cam in my jeg and center everything up. then base on the measurements I got it allow me to find the area I needed to machine out on my dyno cam.

cam lever installed.

Last edited:

Thanks, Ill just add some of the 37670's on the next order to measure out against the HS lifters. Too bad the actual camshaft they did make for the L heads (HSSK and LH195sp's) doesn't show up more often, I would like to compare that to the OHV's version that I have now, They show that OHV one as a replacement for it, as well as the wonky plastic one. Thats where confusion comes in.....they offer that as the alternative for the old HS engines with no indication of tappet change that I have seen anyway.