hi guys,

normally i'd have never gotten involved in a custom mini bike build.

but a buddy on another forum egged me on a little.

since it is a minibike and i am a member here i guess it's ok to post what i'm doing.

i'm not to well versed in minibikes i've never built one before.

i have built a few harleys and it kinda is the direction this bike will take.

mostly because i have piles of parts for harley bikes just lying around.

it's kinda a build off between three friends with a finish date of april 1st.

since one of the guys is a joker that may be his idea of something to do for april fools day.

but i'm having fun so who cares.

these pix on the slide show are so far in this build.

i started about three weeks ago.

hope you like it.

Mini Bike Project Slideshow by drottoconndave | Photobucket

dave

this is my "design" it's on a file card:shrug:

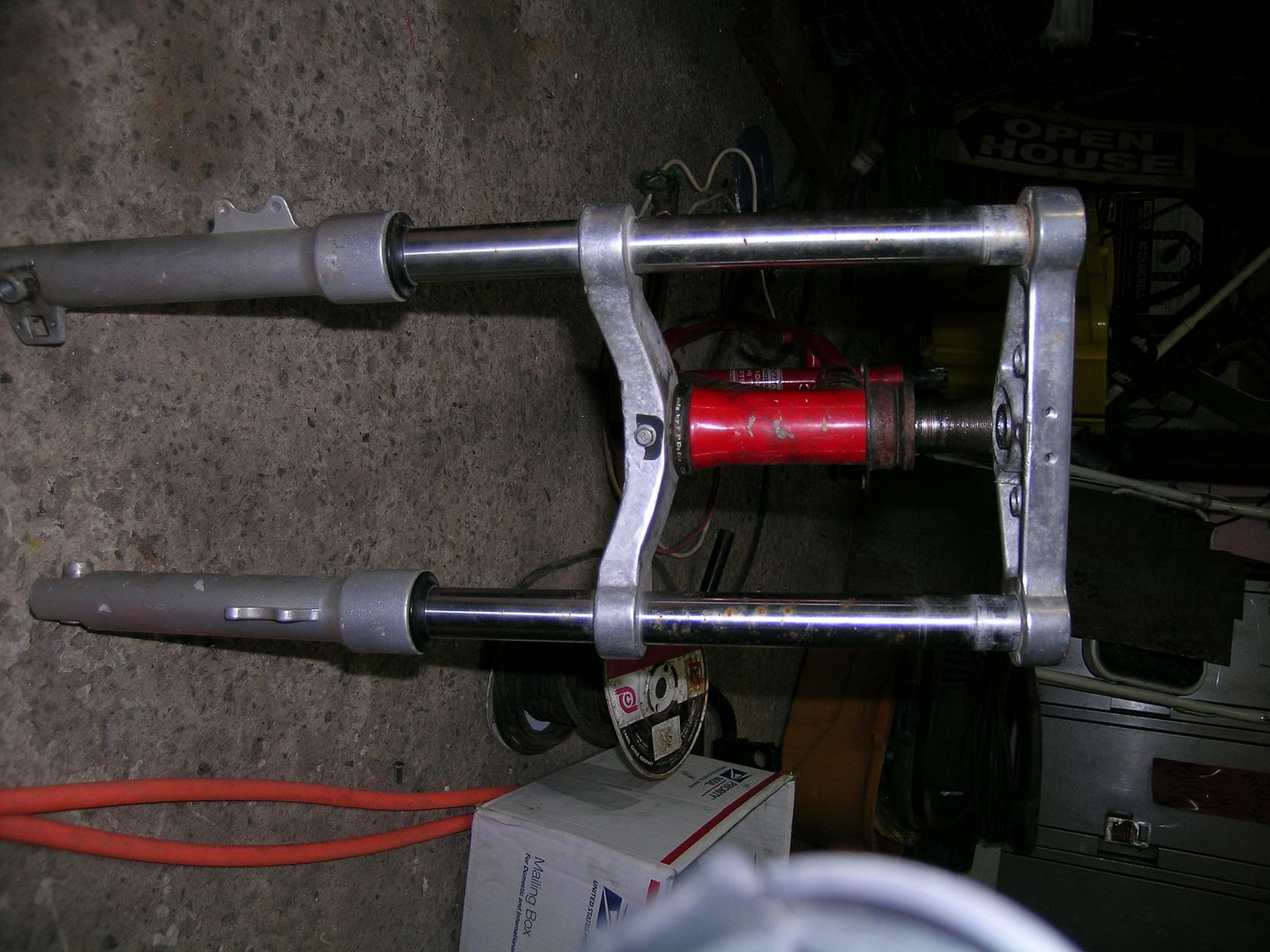

pile o parts

normally i'd have never gotten involved in a custom mini bike build.

but a buddy on another forum egged me on a little.

since it is a minibike and i am a member here i guess it's ok to post what i'm doing.

i'm not to well versed in minibikes i've never built one before.

i have built a few harleys and it kinda is the direction this bike will take.

mostly because i have piles of parts for harley bikes just lying around.

it's kinda a build off between three friends with a finish date of april 1st.

since one of the guys is a joker that may be his idea of something to do for april fools day.

but i'm having fun so who cares.

these pix on the slide show are so far in this build.

i started about three weeks ago.

hope you like it.

Mini Bike Project Slideshow by drottoconndave | Photobucket

dave

this is my "design" it's on a file card:shrug:

pile o parts