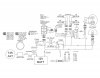

Well, it's been a number of days. Took a bit longer than I expected. The wiring is done and the carb bracket has been fixed. Carb bracket was just a matter of getting the old studs out, then drilling it for machine screws to reattach the carb. Simple fix. The big one was the wiring. I ended up mounting the battery box to the bottom of the seat. You can see in the pictures below it just hugs in there between the frame tubes. The last pic was testing the wiring before beginning wrapping the main run from front to back.

Finally, I got around to taking a short video showing the final lights working and firing it up. As noted in the video, I have to finish wrapping the wires up in electrical tape and clean up the wiring in the headlight, but it's all there and working. Also, apologies for the fingers, I rarely take videos with my phone.

The carb just needs some final adjustments when you give it the gas as it seems to bog down a bit. But that's just a matter of riding it and adjusting as I go.

Finally, I got around to taking a short video showing the final lights working and firing it up. As noted in the video, I have to finish wrapping the wires up in electrical tape and clean up the wiring in the headlight, but it's all there and working. Also, apologies for the fingers, I rarely take videos with my phone.

The carb just needs some final adjustments when you give it the gas as it seems to bog down a bit. But that's just a matter of riding it and adjusting as I go.