Building a mini from scratch

- Thread starter Backyard Builder

- Start date

Hi all!

I worked on the seat today because my butt was about to go on strike due to inhuman working conditions! Plywood seat + 2 hours on bumpy terrain = I can't walk straight anymore :lol:

So, I grabbed some foam, duct tape, fake leather and a T50 stapler and built this:

I also got some foam handlebar grips. They are great, way more comfortable than plastic grips. Best 3$ I've ever spent!

I worked on the seat today because my butt was about to go on strike due to inhuman working conditions! Plywood seat + 2 hours on bumpy terrain = I can't walk straight anymore :lol:

So, I grabbed some foam, duct tape, fake leather and a T50 stapler and built this:

I also got some foam handlebar grips. They are great, way more comfortable than plastic grips. Best 3$ I've ever spent!

The whole thing is so different. I love different. Let me know how the drive system worked. The thought of getting away from a clutch and or torqe converter is something I have pondered for a while.:thumbsup::thumbsup::thumbsup:

The belt drive works surprisingly well. Of course it needs some interesting footwork to operate but I got used to it

For those who may wonder what happened to this project, the shed where the bike is stored is completely buried in the snow, so I can't get to it right now. But I'm thinking about picking up a shovel and just go for it! Or maybe I can use some plywood and just go over all that snow.

Winter can be harsh here :wink:

Hi all!

It's been a while since I last worked on this project, but I finally got the mini out of it's snow prison and I'm back to work :thumbsup: There's a good 8 feet of snow in some places, and I'm not kidding. The swimming pool is invisible now under all that snow! This is getting ridiculous!

Anyway...

I was unsatisfied with the axles I had build previously. The wheels wobbled a bit and the pulley was not perfectly concentric. So, I used a lawnmower rim in the rear and put a plate on it to mount the pulley. The center of this rim is 3/8 thick and is machined so I knew it was straight. I pressed a couple of brass bushings and used some 7/8 drill rod for the axle. Ridiculously overkill!

Same recipe for the front wheel and axle: brass bushings and 7/8 drill rod. So now only the wheels turn and not the whole axle. And everything spins dead straight now!

Next I will make mounts for the rear axle and relocate the brake on the jackshaft. This way the brake will need about 5 times less force to operate, so I will be able to use a regular bicycle brake lever.

Stay tuned :hammer:

It's been a while since I last worked on this project, but I finally got the mini out of it's snow prison and I'm back to work :thumbsup: There's a good 8 feet of snow in some places, and I'm not kidding. The swimming pool is invisible now under all that snow! This is getting ridiculous!

Anyway...

I was unsatisfied with the axles I had build previously. The wheels wobbled a bit and the pulley was not perfectly concentric. So, I used a lawnmower rim in the rear and put a plate on it to mount the pulley. The center of this rim is 3/8 thick and is machined so I knew it was straight. I pressed a couple of brass bushings and used some 7/8 drill rod for the axle. Ridiculously overkill!

Same recipe for the front wheel and axle: brass bushings and 7/8 drill rod. So now only the wheels turn and not the whole axle. And everything spins dead straight now!

Next I will make mounts for the rear axle and relocate the brake on the jackshaft. This way the brake will need about 5 times less force to operate, so I will be able to use a regular bicycle brake lever.

Stay tuned :hammer:

I knew if t were possible to make a belt drive work useing simple easy to qbtain parts you would have the fortitude to see it through to success. I have been following this thread with great interest. You ain't ascared of nothin. I have saved back some belt clutch parts off an old Superior brand reel type mower. I'm now certain they will get used. If you get time I would like your thoughts on the design of a two speed belt drive. Dual pulleys on the engine and dual pulleys on the jack shaft and tighten one or the other?

If you get time I would like your thoughts on the design of a two speed belt drive. Dual pulleys on the engine and dual pulleys on the jack shaft and tighten one or the other?

My homemade four-wheeler desperately needs a new clutch setup, so I think the multi-speed belt drive just might happen :smile:

After i read this I drew up a crude plan. The tensioner would have to have two idlers (my plan). Pretty simple but spacing would be critical. Clearance of both idlers for a split second. Not sure if pushing or pulling the belts would be best. I have a pull system on an old bicycle of mine. Can't wait to see your drawings.

Here are some pics of today's work. I used a pulley hub from a snowblower to mount the disc to the jackshaft. Should be plenty strong.

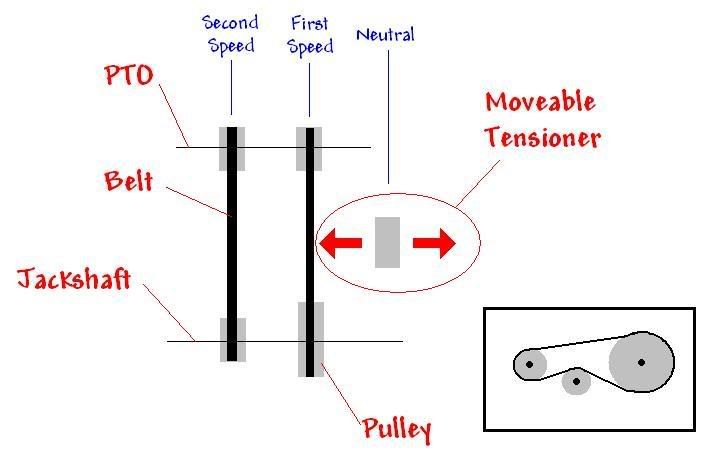

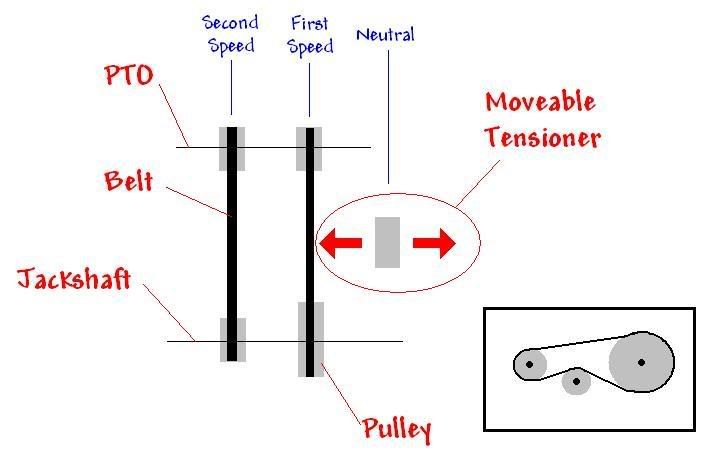

Ok Oldsalt, here's the (crappy) drawing I made showing the 2-speed belt drive. 2 sets of pulleys, 2 belts. The tensioner is mounted on a rail and is moved side to side by the shifter. Tensioning one belt or the other chooses between low and high speed. Releasing the tensioner past the belts provides a neutral. The clutch works as usual, you have to hold the pedal to disengage the belt and a stiff spring puts tension on the belt when you release the pedal.

That's how I plan to do it.

Ok Oldsalt, here's the (crappy) drawing I made showing the 2-speed belt drive. 2 sets of pulleys, 2 belts. The tensioner is mounted on a rail and is moved side to side by the shifter. Tensioning one belt or the other chooses between low and high speed. Releasing the tensioner past the belts provides a neutral. The clutch works as usual, you have to hold the pedal to disengage the belt and a stiff spring puts tension on the belt when you release the pedal.

That's how I plan to do it.

What about having 2 tenioners on one lever, one for each belt. Put them inside of the belts, but one up and one down so that when you push the lever down to engage one of the speeds, the other pulls away from its respective belt, and when you pull up, it disengages the first and engages the second? Just an idea. Ill try and draw a pic.

you almost need to have it something like qucifer setup. where the belts could be engage and disengage as fast as possible or it may feel like you are trying to shift a old tractor. it might work better if the idlers are on the outside of the belts too. so the idler is pushing the belt tight,also you would want it set up where you could bang it into second gear with out taking your hands off the gas and steering:thumbsup:

............*.............

............*.............

............*.............

............*.............