Guys, I need one of these bagger attachment brackets for the back of a Craftsman LTX1000 lawn tractor.

I have back and neck spinal issues still, and my son got me this lawn tractor because using a push mower is Hell. I'm hoping to install a used bagger on the back for leaf pickup during the fall. Sears sells the bracket brand new, but I just lost my job after 28 years due to a workforce reduction, and am low on cash. One of the parent companies just bought out the other 1/2 of the business, and they are wiping out all the duplicate departments over a two year timeframe. I got dumped in the first batch Sept 30. The company replaced us with much cheaper Indians. Can you say "Cost Synergies"?

Anyway, if somebody has one of these laying around for cheap or free, I can pay shipping (Paypal?) to get it to me in mid-Michigan. It bolts onto the back of the tractor, and the bagger unit bolts onto it.

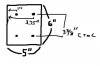

I found this pic on the web (not my actual tractor or bagger), but if you look close, it sort of shows you how this bracket is mounted on the back of the tractor:

Thanks!

I have back and neck spinal issues still, and my son got me this lawn tractor because using a push mower is Hell. I'm hoping to install a used bagger on the back for leaf pickup during the fall. Sears sells the bracket brand new, but I just lost my job after 28 years due to a workforce reduction, and am low on cash. One of the parent companies just bought out the other 1/2 of the business, and they are wiping out all the duplicate departments over a two year timeframe. I got dumped in the first batch Sept 30. The company replaced us with much cheaper Indians. Can you say "Cost Synergies"?

Anyway, if somebody has one of these laying around for cheap or free, I can pay shipping (Paypal?) to get it to me in mid-Michigan. It bolts onto the back of the tractor, and the bagger unit bolts onto it.

I found this pic on the web (not my actual tractor or bagger), but if you look close, it sort of shows you how this bracket is mounted on the back of the tractor:

Thanks!

Last edited: