Replacing Starter Rope

The second most frustrating thing about recoil starters is replacing the rope. The spring is the worst.

The most important thing to do is get the right diameter starter cord. The Briggs L-head manual posted as a sticky gives the diameters/lengths for engines 9000 series and up. It doesn't have the 8000 series or the 6000 series, so you need to take a piece of the original cord with you when you go to the hardware store or small engine shop. Trying to stuff in the wrong size cord is a nightmare.

Extend the starter cord fully out and use a small clamp to secure the recoil in place. Remove the knot and save the rope, you'll need it to get the right length.

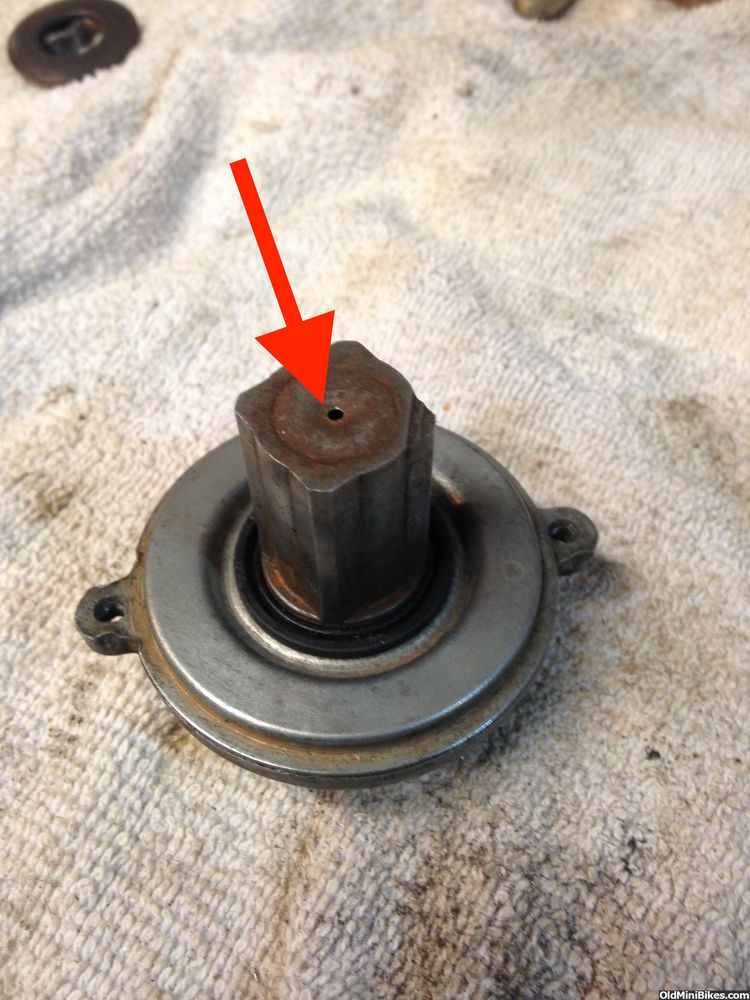

Of critical importance is alignment of the knot hole to the handle hole. I used a piece of wire to get it lined up correctly. <<The rope does not simply wind around the spool>> rather it passes through a small tube and then to the knot hole and is shown by the yellow line below.

Cut the rope about 2" longer than needed and use a lighter to slightly burn the end so that it's a little "glob" on one end.If you're really lucky, you can slide the rope right in and pull the end out with needle nose pliers. Otherwise, grab a small, solid diameter wire (18g or smaller) or your spouse's needle point hook and push the rope through.

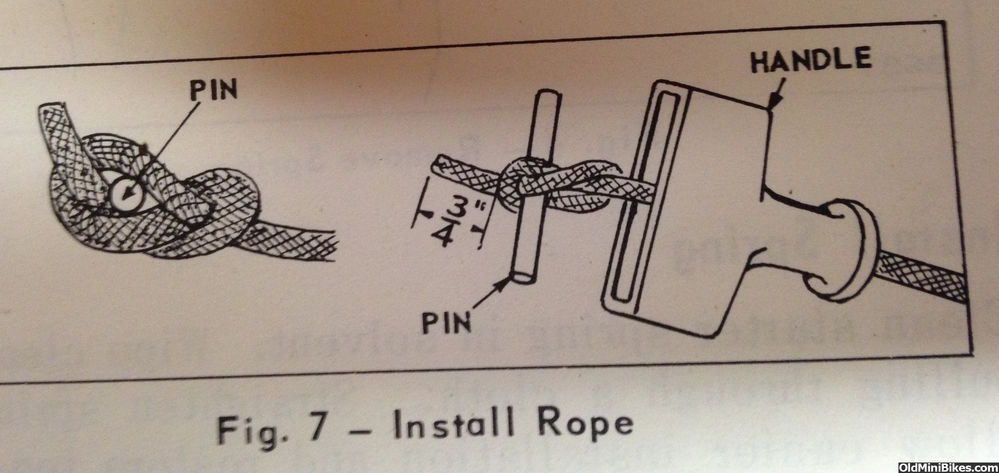

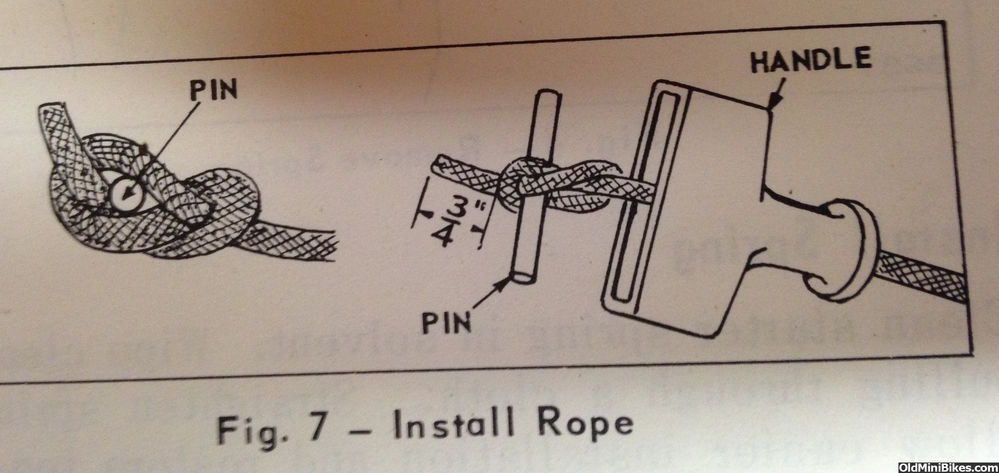

Then, loosely make a knot on the other end as shown below (be sure to put the pull handle on first) and release the clamp to allow the cord to recoil into the starter.

Adjust the length as needed and tie the knot as shown above after burning the end. And, you're done.

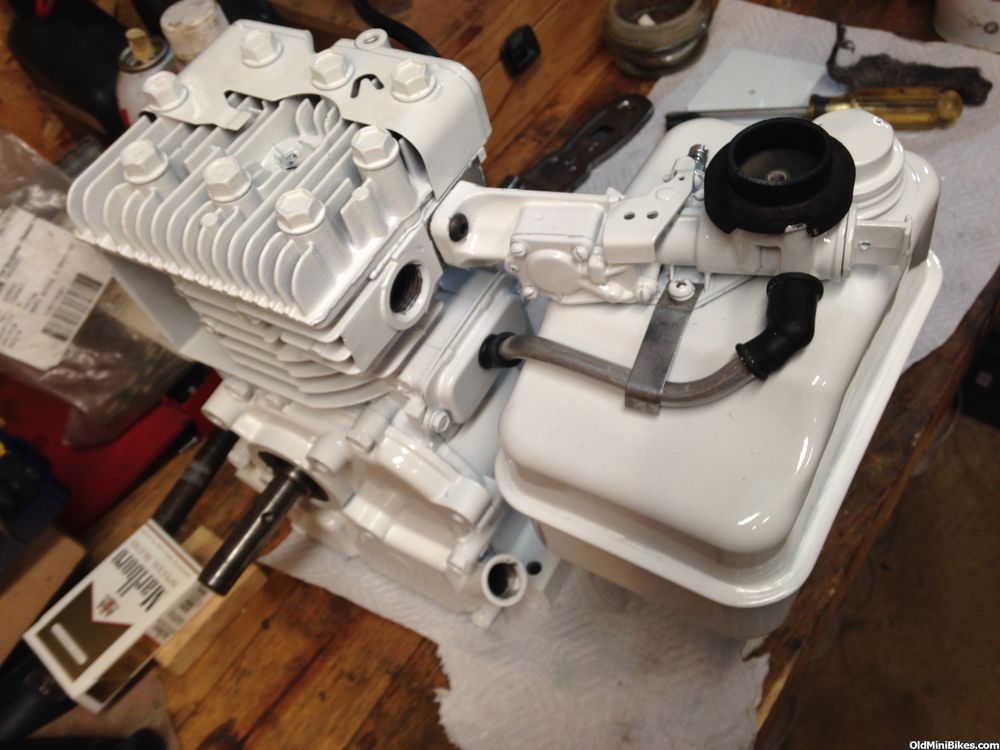

BTW, I used Rustoleum to break down the rust on the shroud and I need to re-sand to get the flash rust off.

The second most frustrating thing about recoil starters is replacing the rope. The spring is the worst.

The most important thing to do is get the right diameter starter cord. The Briggs L-head manual posted as a sticky gives the diameters/lengths for engines 9000 series and up. It doesn't have the 8000 series or the 6000 series, so you need to take a piece of the original cord with you when you go to the hardware store or small engine shop. Trying to stuff in the wrong size cord is a nightmare.

Extend the starter cord fully out and use a small clamp to secure the recoil in place. Remove the knot and save the rope, you'll need it to get the right length.

Of critical importance is alignment of the knot hole to the handle hole. I used a piece of wire to get it lined up correctly. <<The rope does not simply wind around the spool>> rather it passes through a small tube and then to the knot hole and is shown by the yellow line below.

Cut the rope about 2" longer than needed and use a lighter to slightly burn the end so that it's a little "glob" on one end.If you're really lucky, you can slide the rope right in and pull the end out with needle nose pliers. Otherwise, grab a small, solid diameter wire (18g or smaller) or your spouse's needle point hook and push the rope through.

Then, loosely make a knot on the other end as shown below (be sure to put the pull handle on first) and release the clamp to allow the cord to recoil into the starter.

Adjust the length as needed and tie the knot as shown above after burning the end. And, you're done.

BTW, I used Rustoleum to break down the rust on the shroud and I need to re-sand to get the flash rust off.

Last edited: