I have been looking to build a welding table for a while, as the ones that are available are pretty pricey and not what I want... the one i would love, my dream table, is way out of my budget... so... since I have the capability to build one... I decided to build one the way I wanted... although this is not a copy, it was very much so inspired by the $4300 strong hand tools welding table I would love to have... this will cost me a fraction of that... I will try to document this as I go along... Will be building two tables, but they will fit together like a puzzle.... will also use the already available clamps etc... and I can program and put together custom fixtures for misc projects at very little cost to me, other than material...

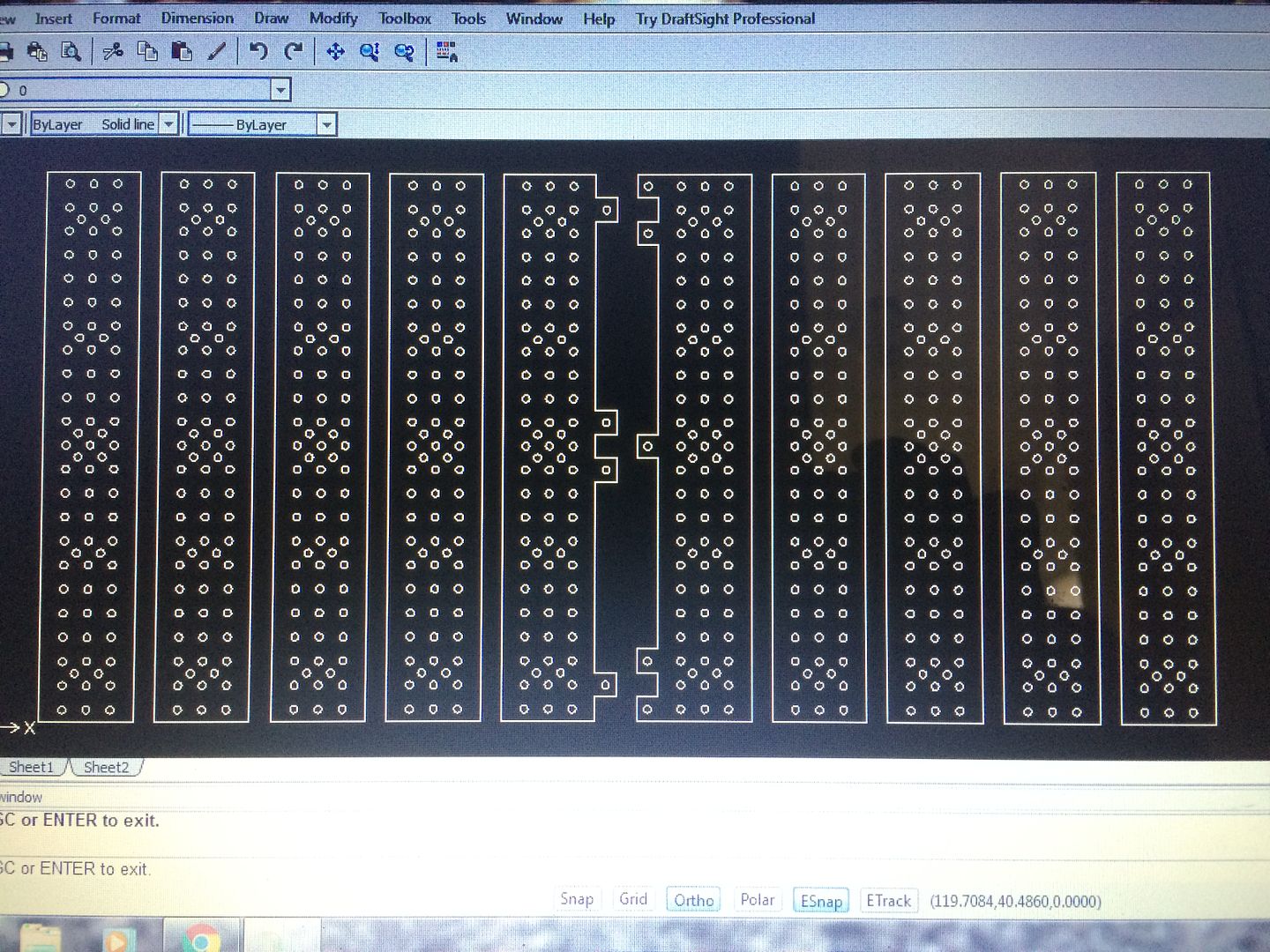

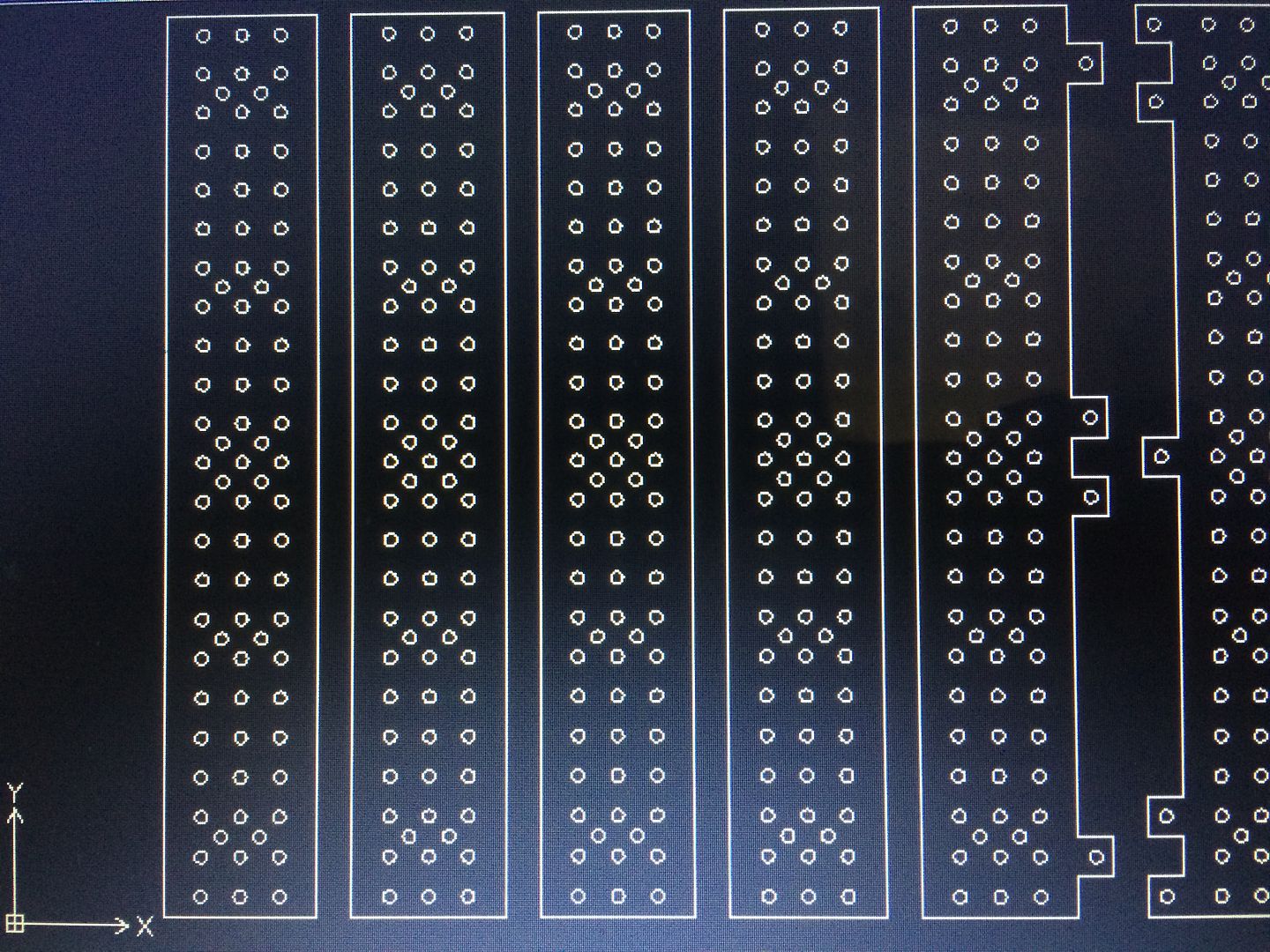

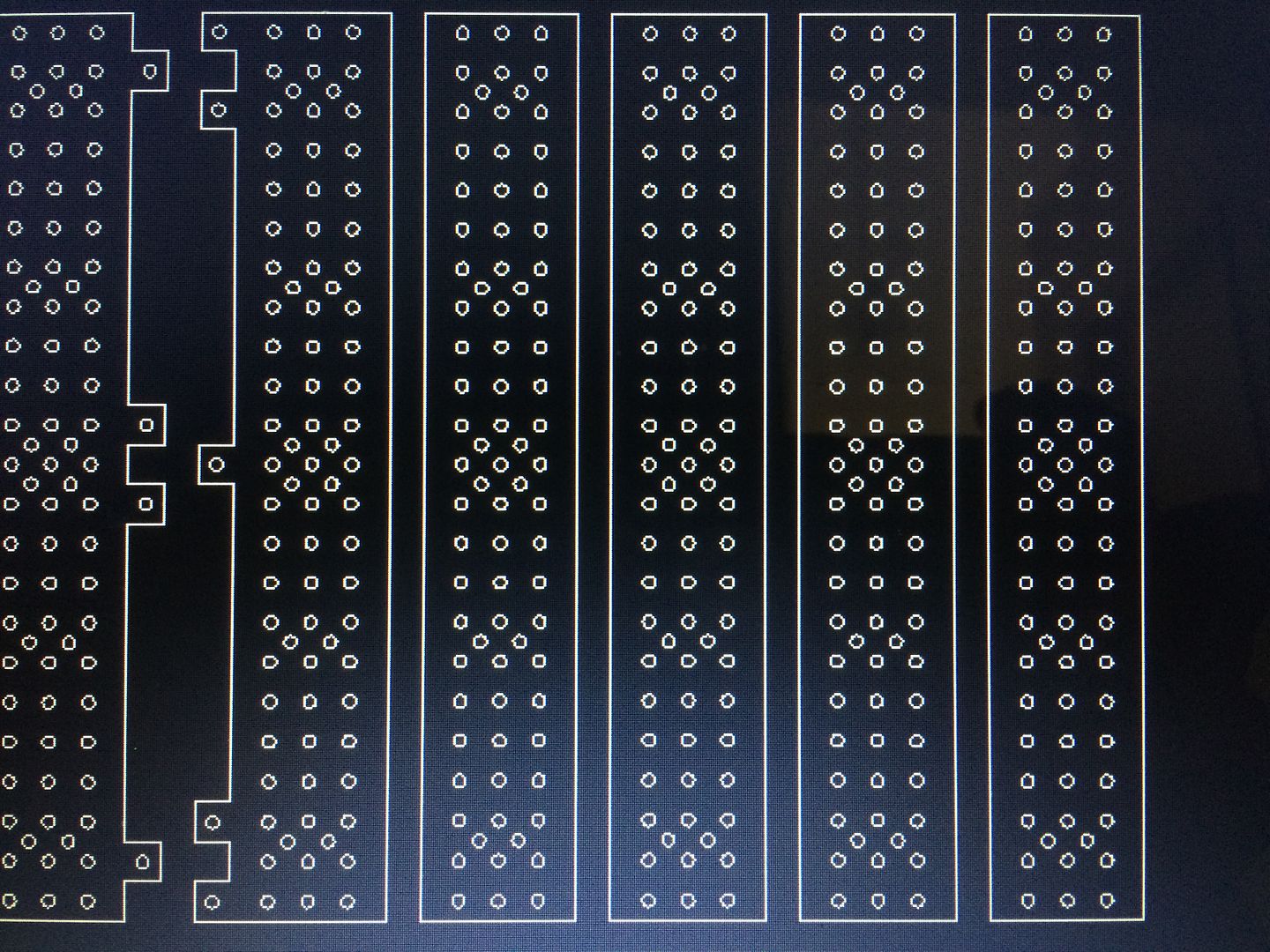

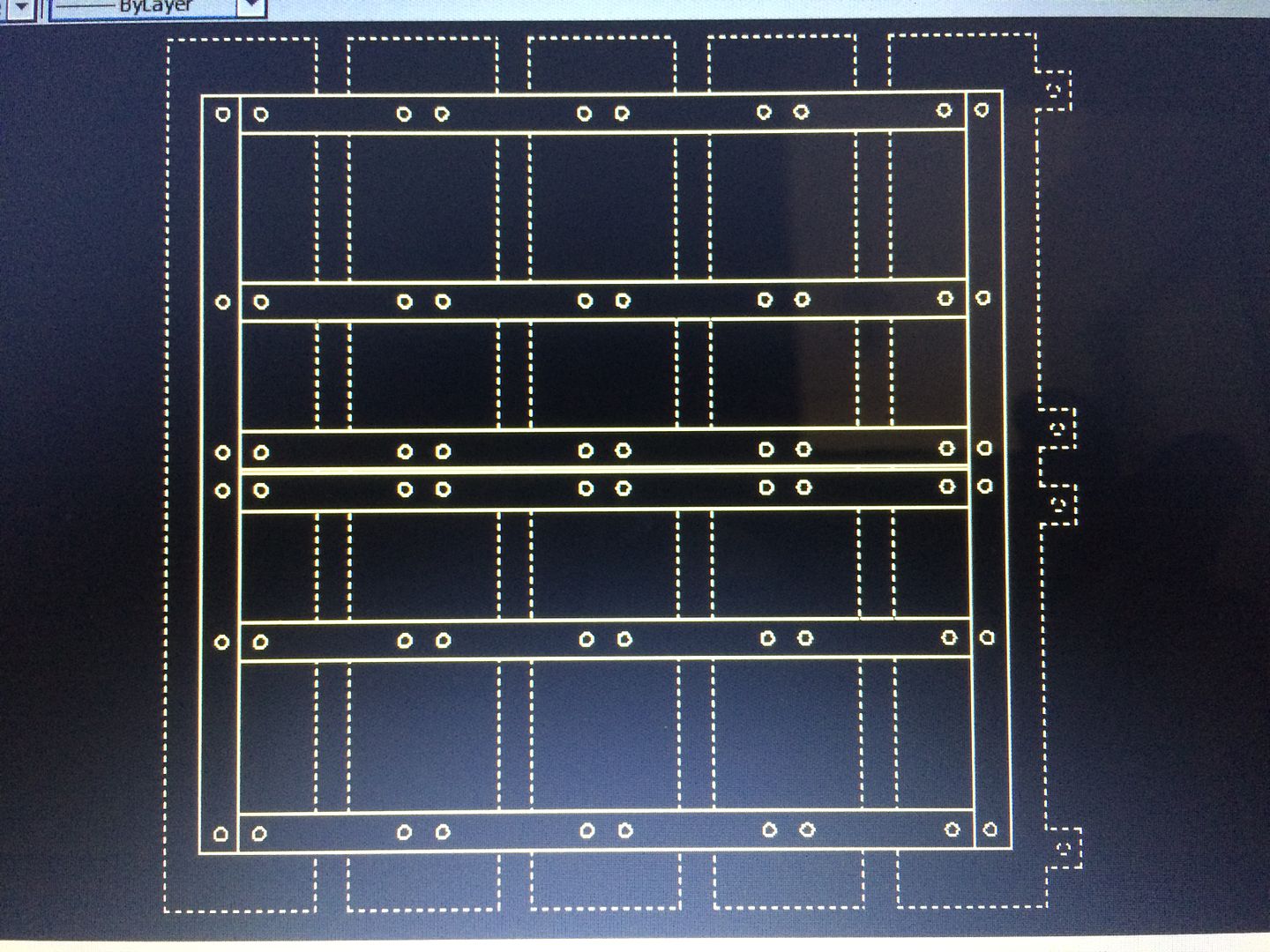

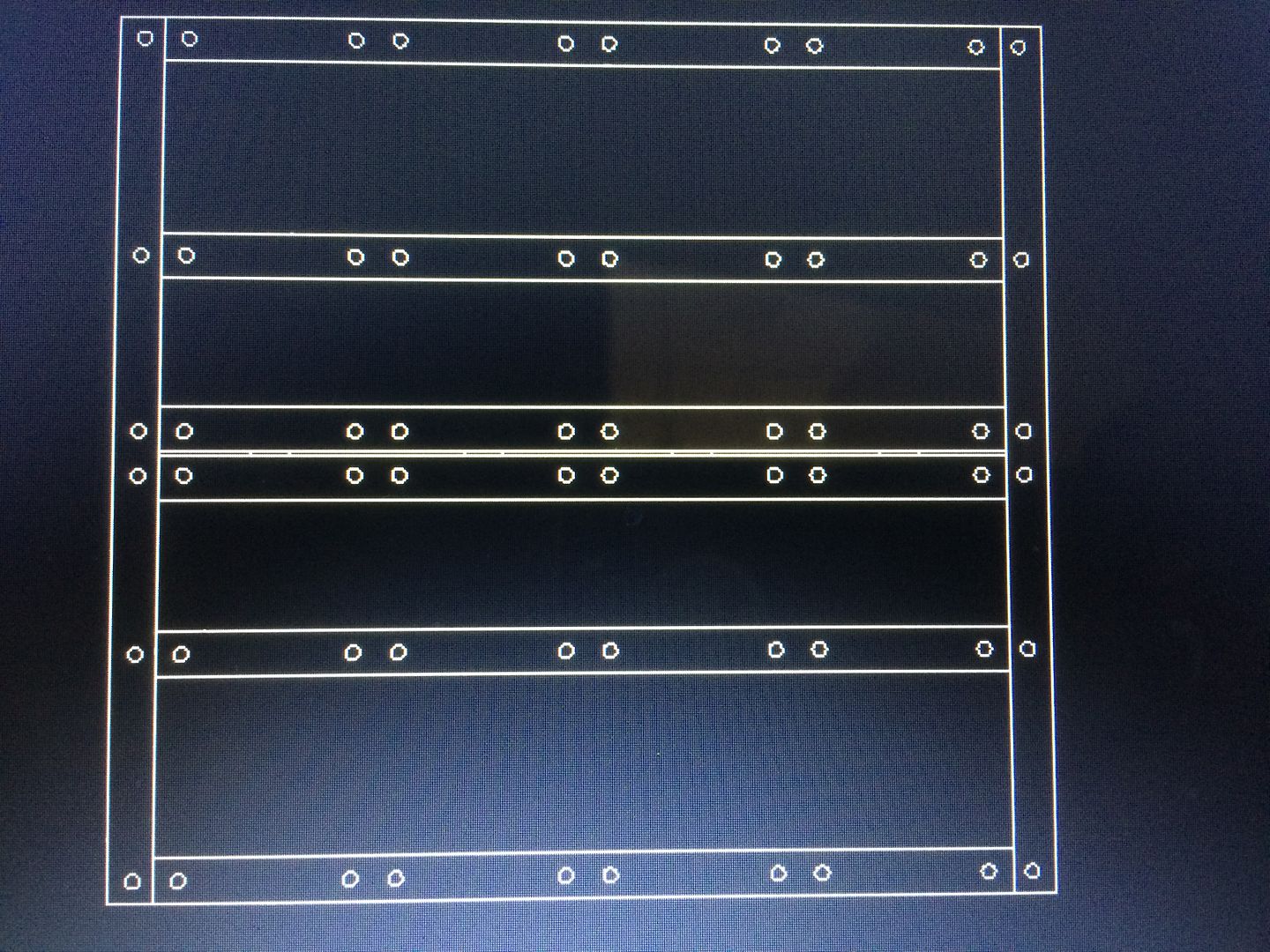

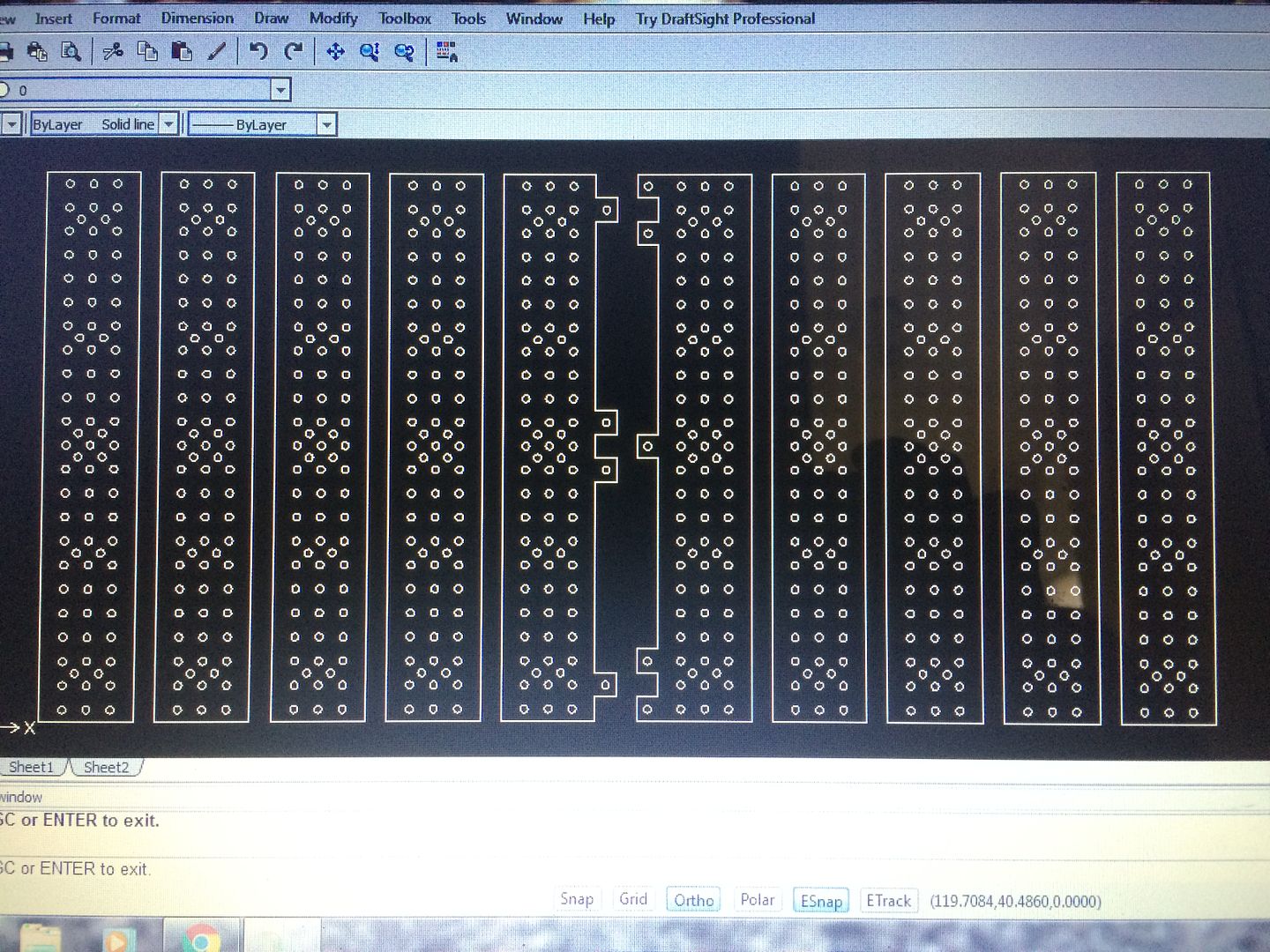

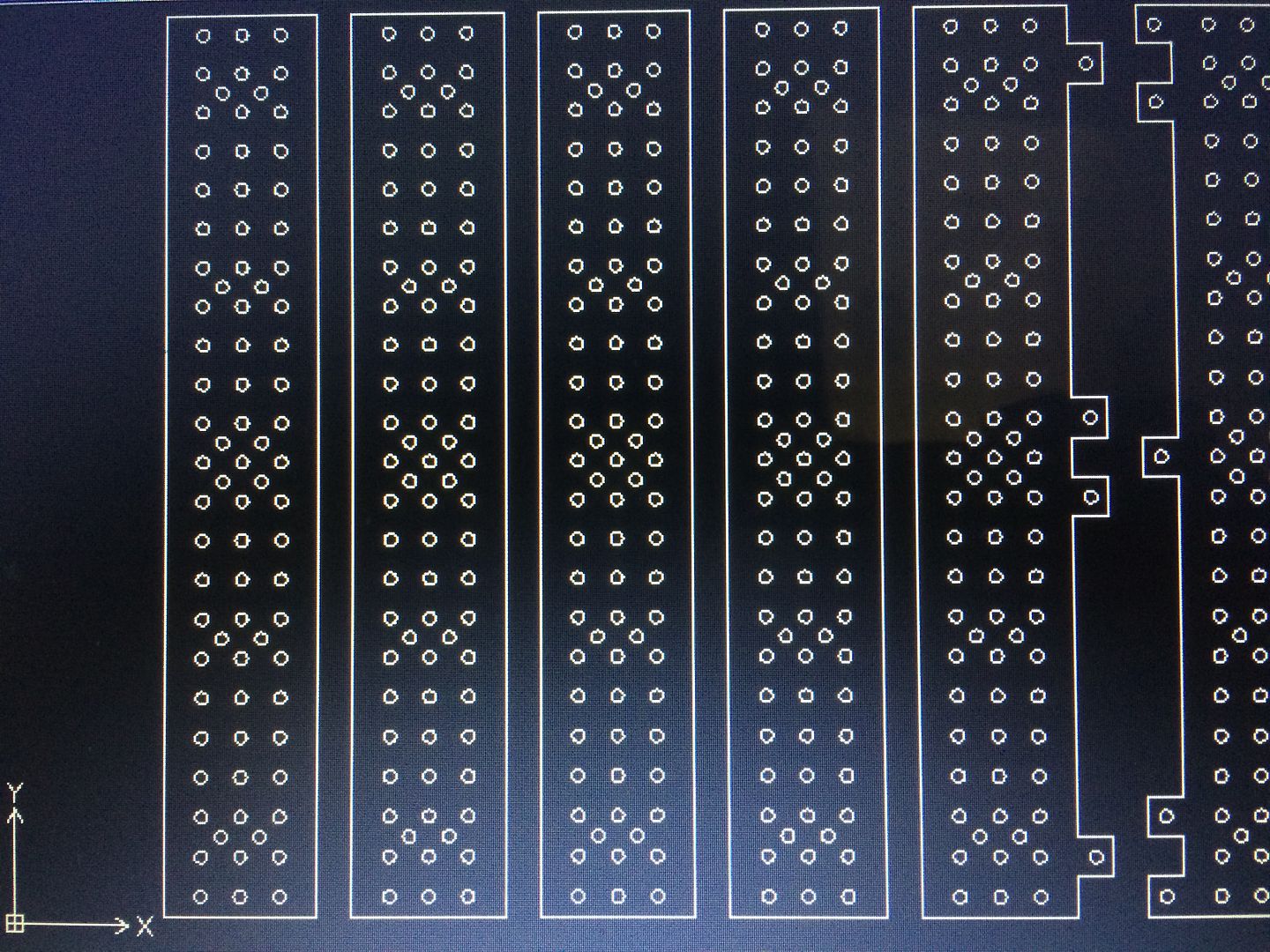

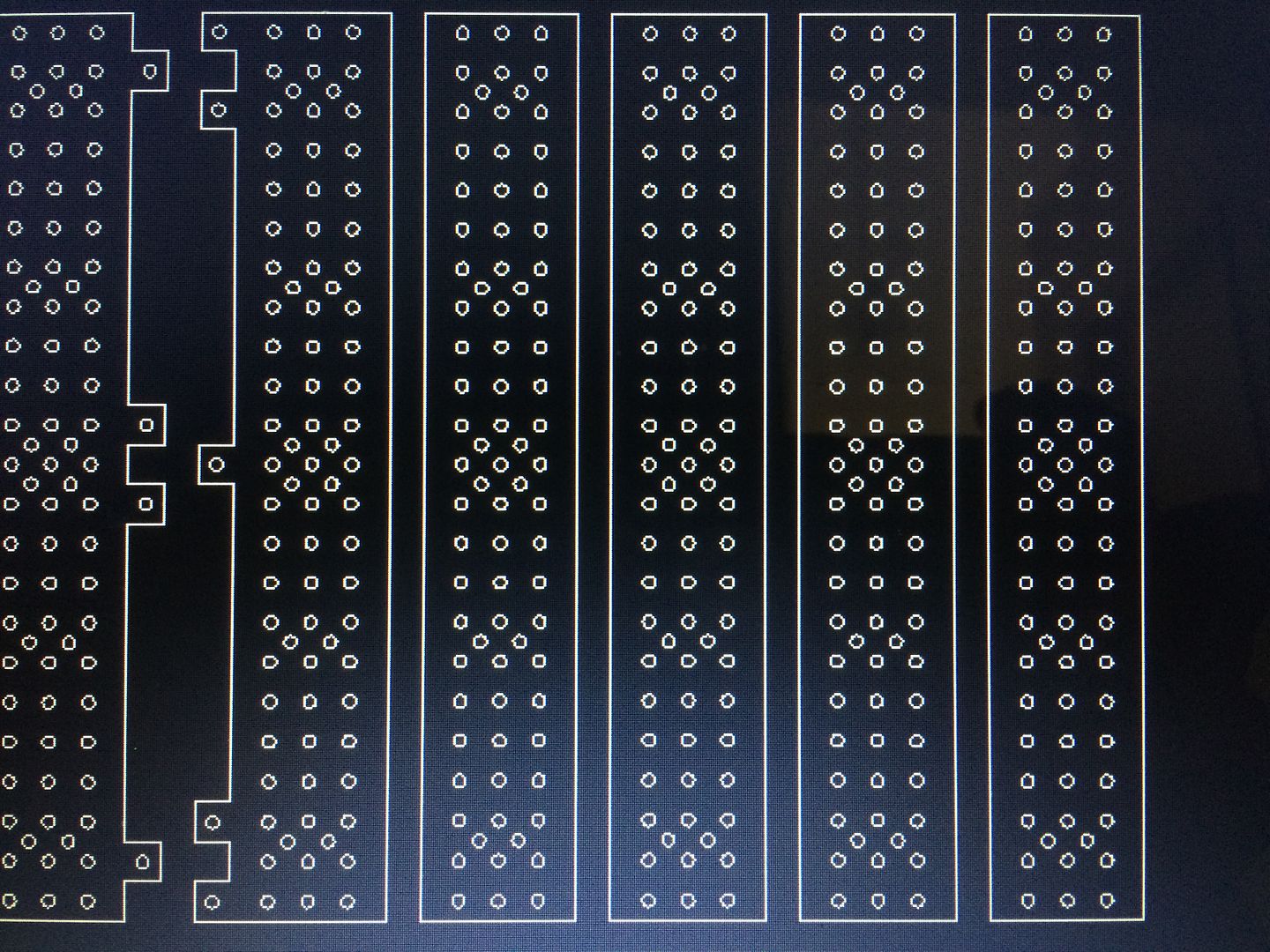

Modular welding table... approx. 96" x 46" when bolted together... holes are .625", spacing 2", between plates, including when bolted together 1.75"... so that i would have no problem using anything available from strong hand tools... or other available clamps and fixture systems... this will come in handy for future minibike and non minibike related projects...

Modular welding table... approx. 96" x 46" when bolted together... holes are .625", spacing 2", between plates, including when bolted together 1.75"... so that i would have no problem using anything available from strong hand tools... or other available clamps and fixture systems... this will come in handy for future minibike and non minibike related projects...