Looking at the tubes I've crimped, I still think welding those extra thick washers to the inside faces could be a good thing. Might be comforting to have the "smooth" part of those axles resting on a little wider surface.

I know exactly what you are talking about. I don't know that welding washers on would provide any more strength than using washers in the assembly, or how the beads would impede spacers, etc. but it would probably make it stronger. Has it been an issue? I've never had issues, except for some cracking and corrosion induced issues that did require welding.

Here are the photos I took from a bike I built last year for coping in the rear axle. I ended up cutting it all back off, and going with slotted plates, but you can see what I was up to. I did use the thicker bushing material, but I purchased a 12" length of 5/8 with an OD of 1" from Ebay. Ordering specific sizes doesn't work if you're making your own stuff, and engineering widths for wheel, etc.

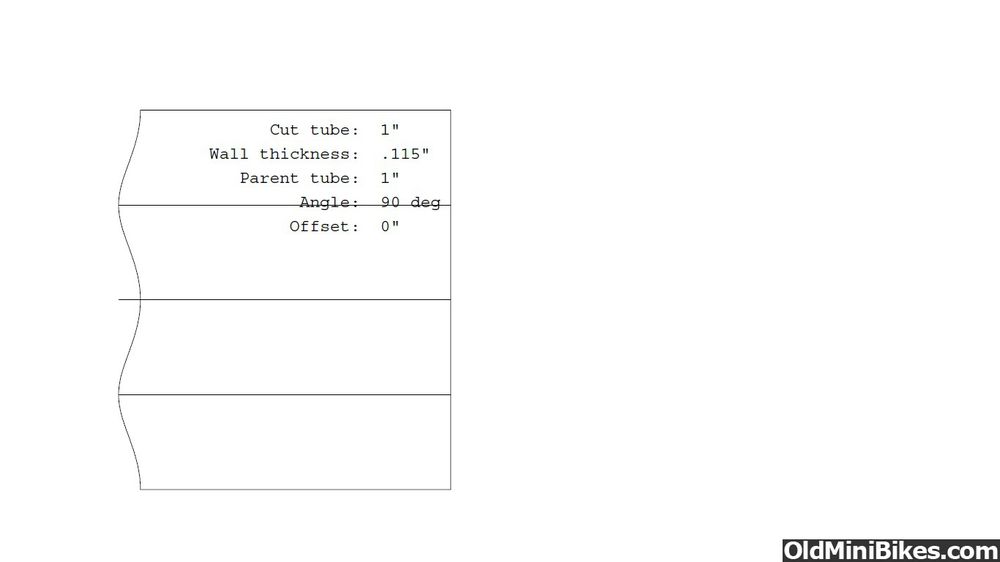

Coping Pattern:

Rear Frame Cut to Pattern:

Ready to Weld:

Finished- Before Cutting it Off and Starting Over Again: