briggs eyebrow trim - how did I do?

- Thread starter Mr.GhettoRig

- Start date

- Tags briggs eyebrow trim

and here's how the good block sits as of this afternoon, I was a lot more careful with the dremel this time :thumbsup:... I'll take care of the lump tomorrow.

I was thinking... I'm doing all of this I might as well upgrade to a higher lift cam. Supposedly the block likes to break somewhere around the lifter area and you're supposed to weld more material there. :shrug: does anyone have a picture of that? cause I have an IDEA but I don't know for sure. I know I know I'm asking somewhat unrelated questions, but I've already got 3 or 4 threads started on this page and I'm trying not to flood the engine section with all my questions. ut:

ut:

I was thinking... I'm doing all of this I might as well upgrade to a higher lift cam. Supposedly the block likes to break somewhere around the lifter area and you're supposed to weld more material there. :shrug: does anyone have a picture of that? cause I have an IDEA but I don't know for sure. I know I know I'm asking somewhat unrelated questions, but I've already got 3 or 4 threads started on this page and I'm trying not to flood the engine section with all my questions.

I think you did a good there chum, but I am not a flat head expert.

Now that deck looks like an old Honda G motor with a bit of work done.

I think you did a good there chum, but I am not a flat head expert.

I think you did a good there chum, but I am not a flat head expert.

Dude, you really have a knack for stuff. Can't belive ya can't find a job. Or not going to tech school or something.

Very nice job.

Very nice job.

as for school, I just finished 1 year at charlotte tech for automotive service technology.. which is basically the same auto class they kicked out of normal highschool- but it's ASE certified, which I will also be when I'm finished. Two years to go and one of them is free. :thumbsup:

oh and thanks buckeye! :thumbsup:

haha thanks, It's still not 100% best job ever done in the world.. but it's a hell of a lot better than my first attempt. pays to be patient. :thumbsup: now I gotta invest 20 bucks for 3 dremel brushes to shine up my ports... is it just me or does it seem like any and all dremel bits are a bit overpriced? :shrug:

stuffs not bad i have bought some of the small tools from there and they seem to be of ok quality . got a dial caliper and its ok not 200% but good enough for most work . also the big assortment kits can be alot cheaper then some of the little ones . :thumbsup:

well kinda but it depends on where you buy your stuff at . like here Widget Supply: Dremel

stuffs not bad i have bought some of the small tools from there and they seem to be of ok quality . got a dial caliper and its ok not 200% but good enough for most work . also the big assortment kits can be alot cheaper then some of the little ones . :thumbsup:

stuffs not bad i have bought some of the small tools from there and they seem to be of ok quality . got a dial caliper and its ok not 200% but good enough for most work . also the big assortment kits can be alot cheaper then some of the little ones . :thumbsup:

Looks really good! I just did one on a 5hp motor have. I put a 4 degree flywheel meet in it and an electronic ignition cool and a header, motor runs and sounds good.

Here is a picture of the lifter bore weld to show you what it looks like. I plan on doing this to one once I find a good I/C motor for my new rod.

Here is a picture of the lifter bore weld to show you what it looks like. I plan on doing this to one once I find a good I/C motor for my new rod.

pretty :drool: I bet that was pricy- and probably well worth the money too.

You know what was probably a better (initial) investment? The $15 die grinder on the right side. Being able to cut the speed down greatly improves control. Dremels, IMO, spin too fast and don't have enough torque, making them harder to control.

And now I must attend to an ant invasion in the kitchen....:angry:

it looks good, you just need to blend or smooth up the two sides just in front of the valve . Next look into removing the ez spin compression release from the cam it will improve your low end power and torque

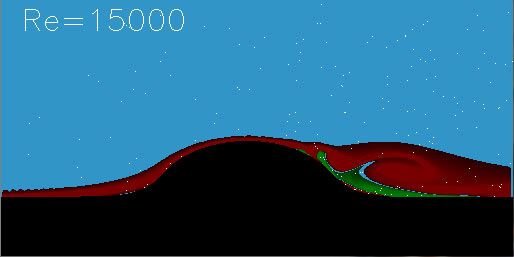

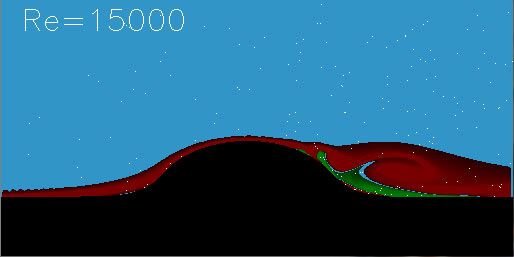

OK Here's my 2 cents worth. When thinking about flow, associate it with a stream of water. When the stream is wide and deep, the water flows slowly. When the same stream has a narrow, shallow part, the water speeds up. If there is a place that "juts" out from the edge, the water will "swirl" on the downstream side of the projection. Look at the 2 professionally drawn works of art that I included here. Hopefully you can figure out what I'm trying to show. If you can't visualize what I am trying to get across, don't worry. You are probably just "normal". Seriously, in ports on automotive heads or anywhere you are trying to improve flow (here we are talking about small engines) you are trying to make the least restrictive area for the exhaust or intake to flow. As stated b/4, sharp edges cause hot spots. They also provide a spot for "swirl" (look at picture A). Swirl will impede flow. I'm sure some of these serious engine gurus can explain it better that me. But, if a big dummy like me can grasp the concept, it can't be to difficult for the newer enthusiasts that want to try their hand at these modifications. BTW, any of you smart a$$es that want to make fun of my drawings, knock yourself out. Those of you that are familiar with me know I'm a big boy and can take it :laugh: The main thing is that we all contribute what we know and help each other enjoy a wonderful hobby. Now, I need to go so I can get a nap in b/4 I eat. Then after I eat, it will be time for bed. Ahhhh, what a life. Eating and watching TV for a living.

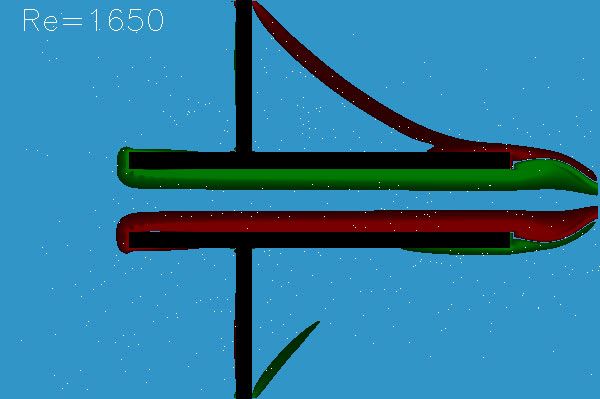

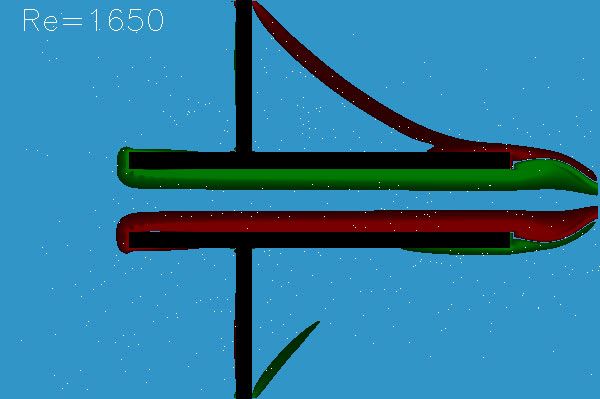

This is just for a very generalized illustration of 2D flow around the two profiles. Real 3D flow/Computational Fluid Dynamics is far more complex and system-intensive to model. The swirly bits are where fuel is likely to drop out of suspension. The Re=15000 equates to a very high velocity. The standing waves at the far left indicate sonic speed.

This might give insight into why a velocity stack flows better than a straight tube:

A sharp or square edge makes the tube's effective diameter smaller.

This might give insight into why a velocity stack flows better than a straight tube:

A sharp or square edge makes the tube's effective diameter smaller.