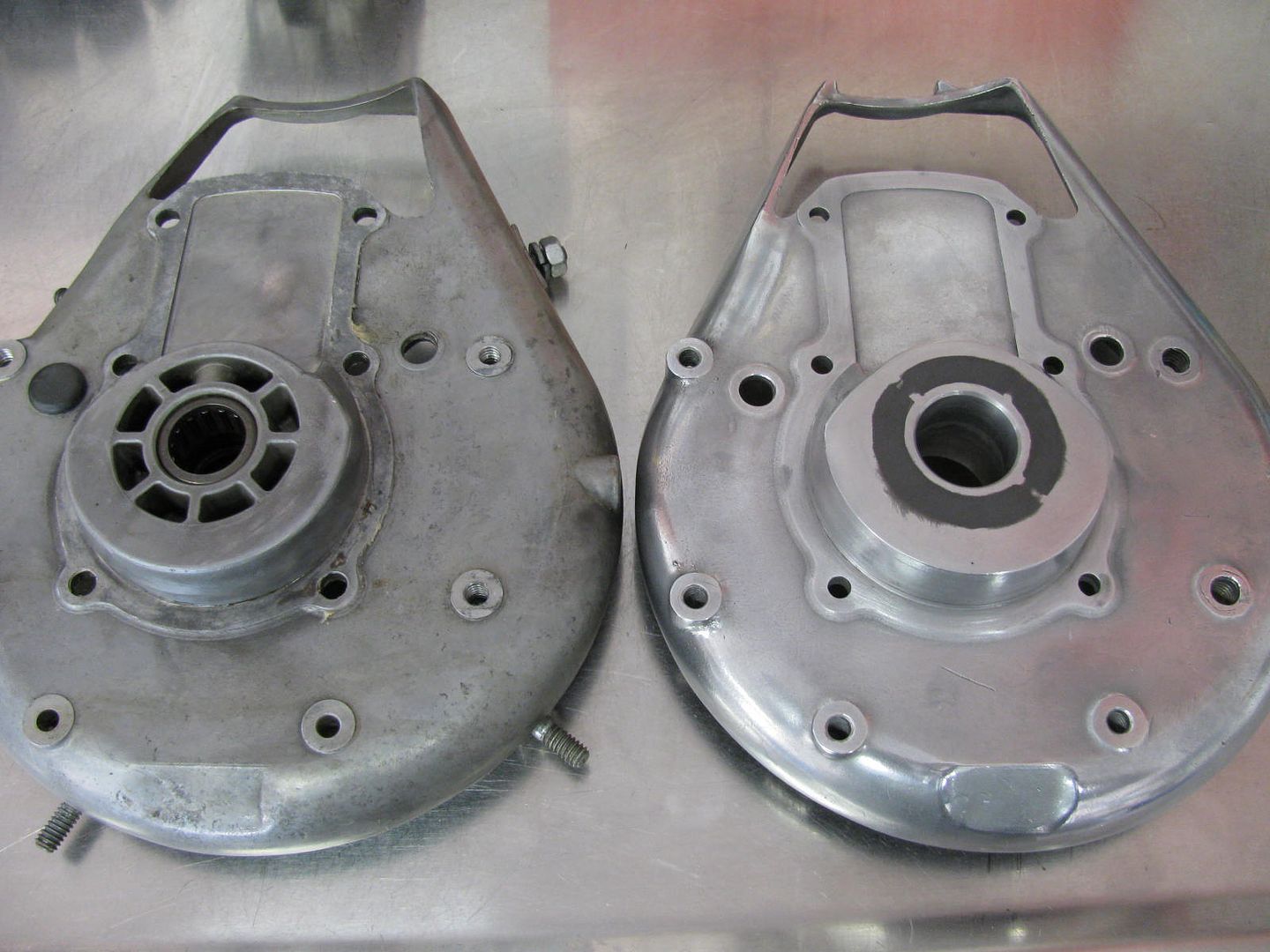

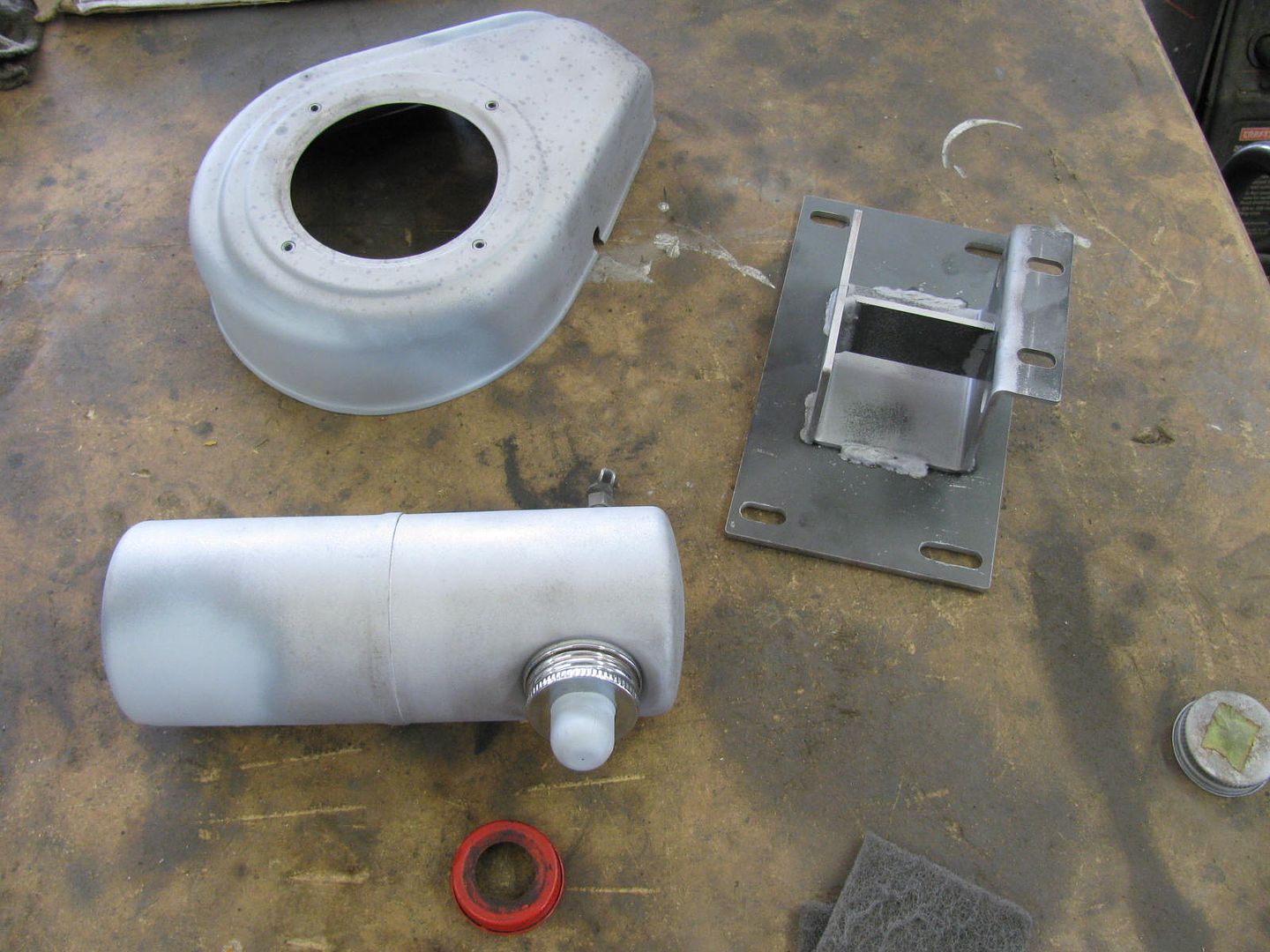

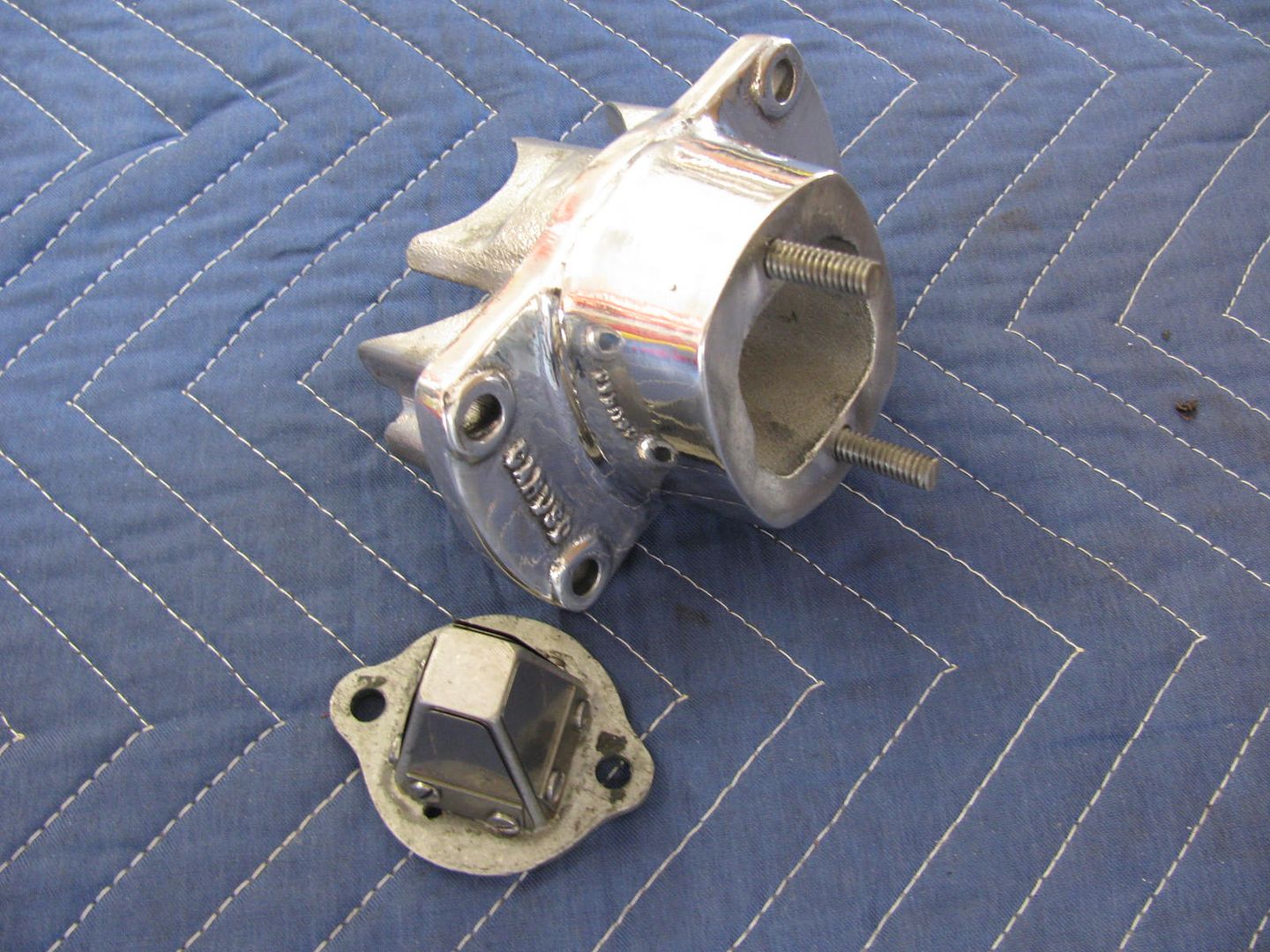

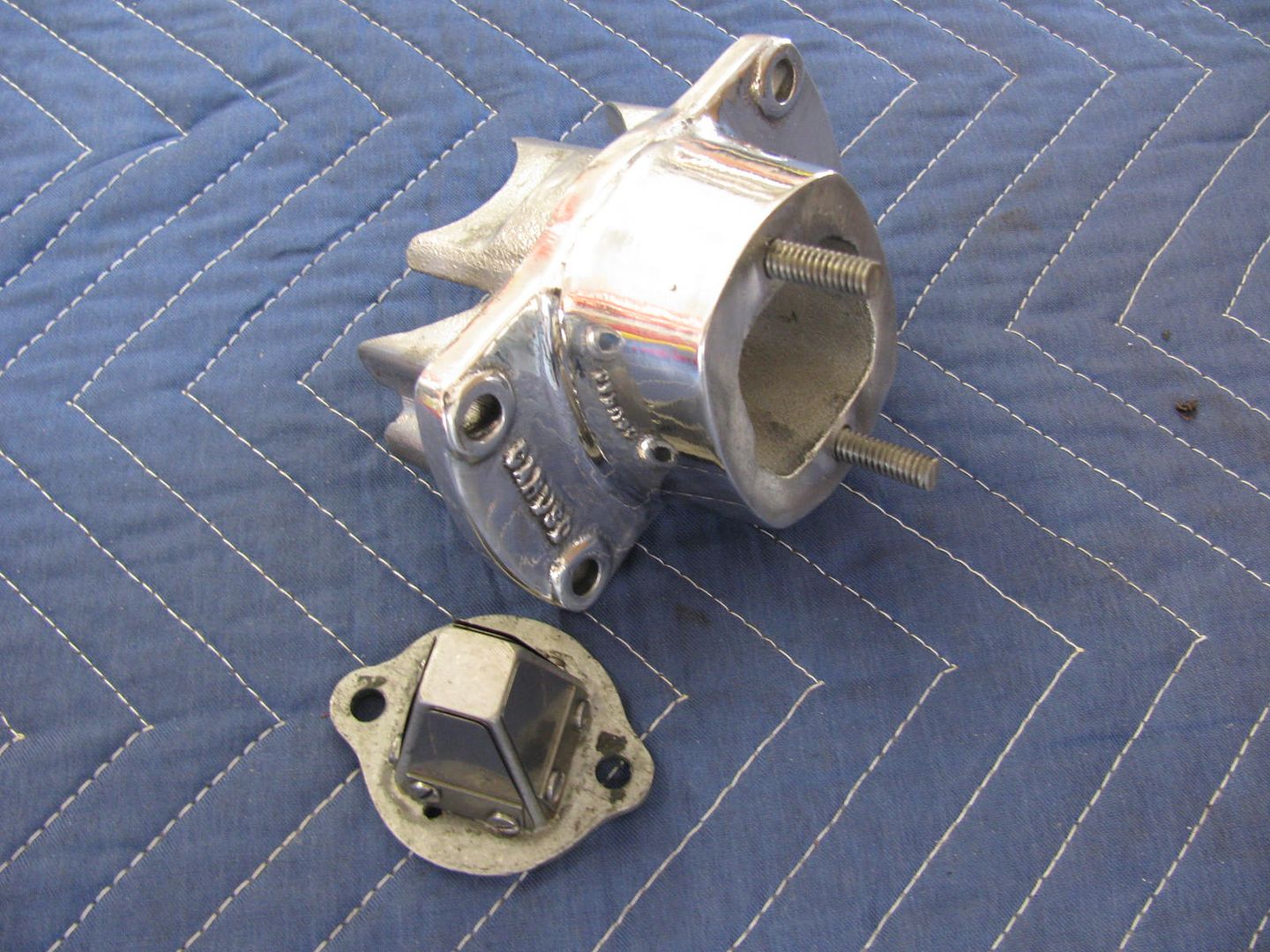

I just picked up a 580 that has a Caruso or maybe capuso centered intake/stuffer on it. Kinda looks like a go power from what I have seen, not sure what the reed plate is I am guessing maybe Gem (if It is can I get new reeds for it :shrug

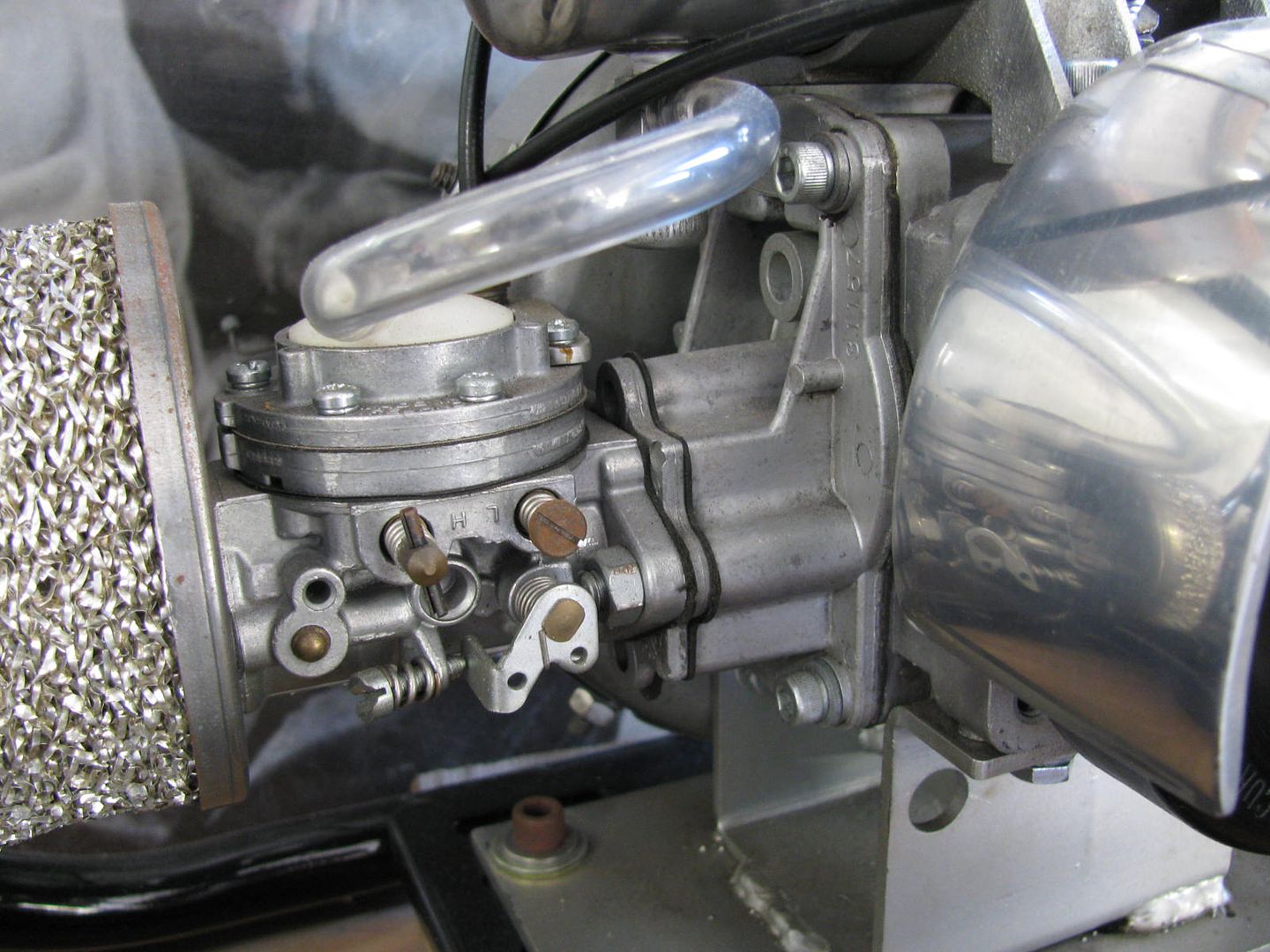

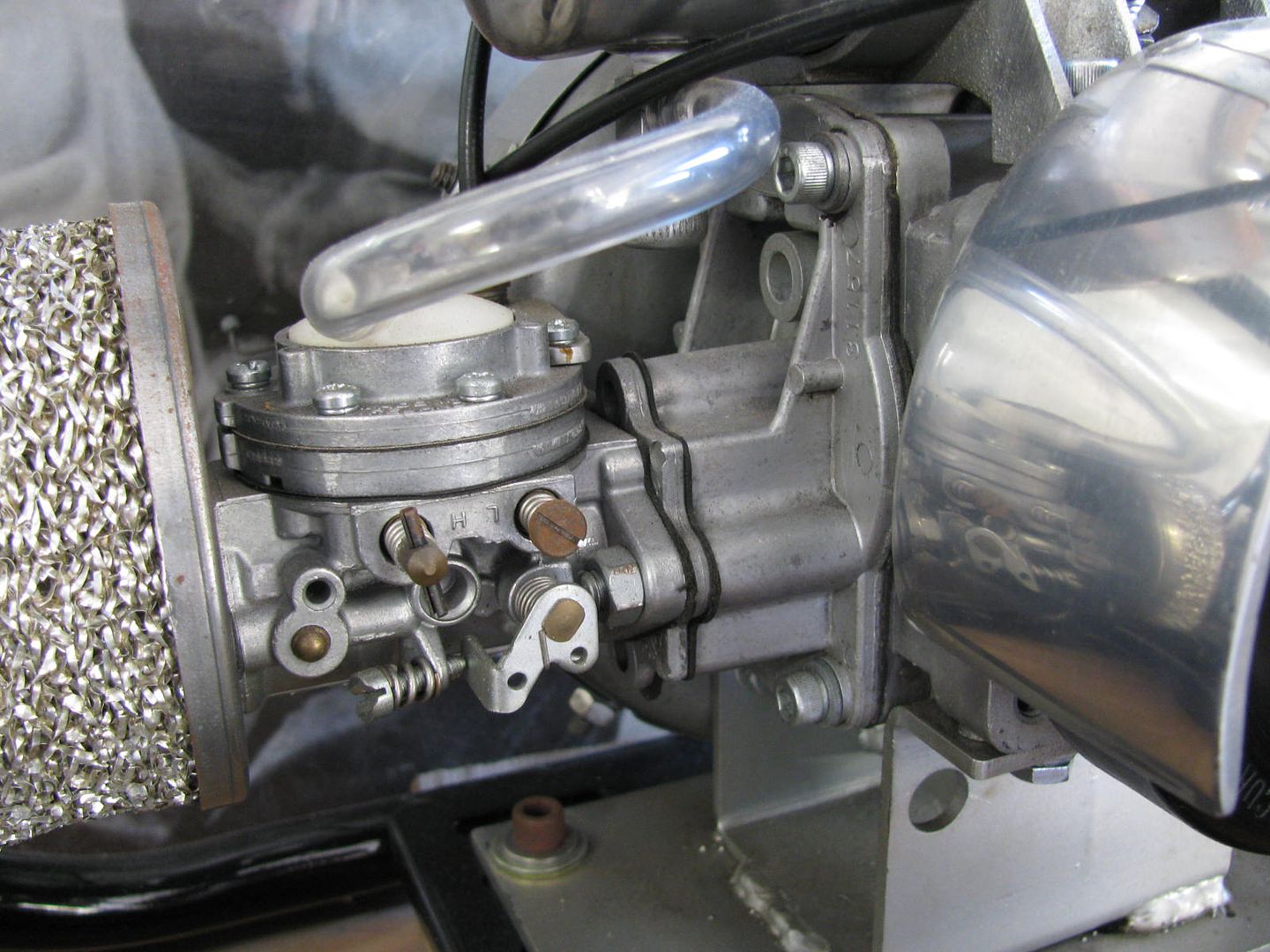

Anyone ever heard of it, and whats it gonna do for me as opposed to what appears to be stock offset intake/reed setup I have on a 700?

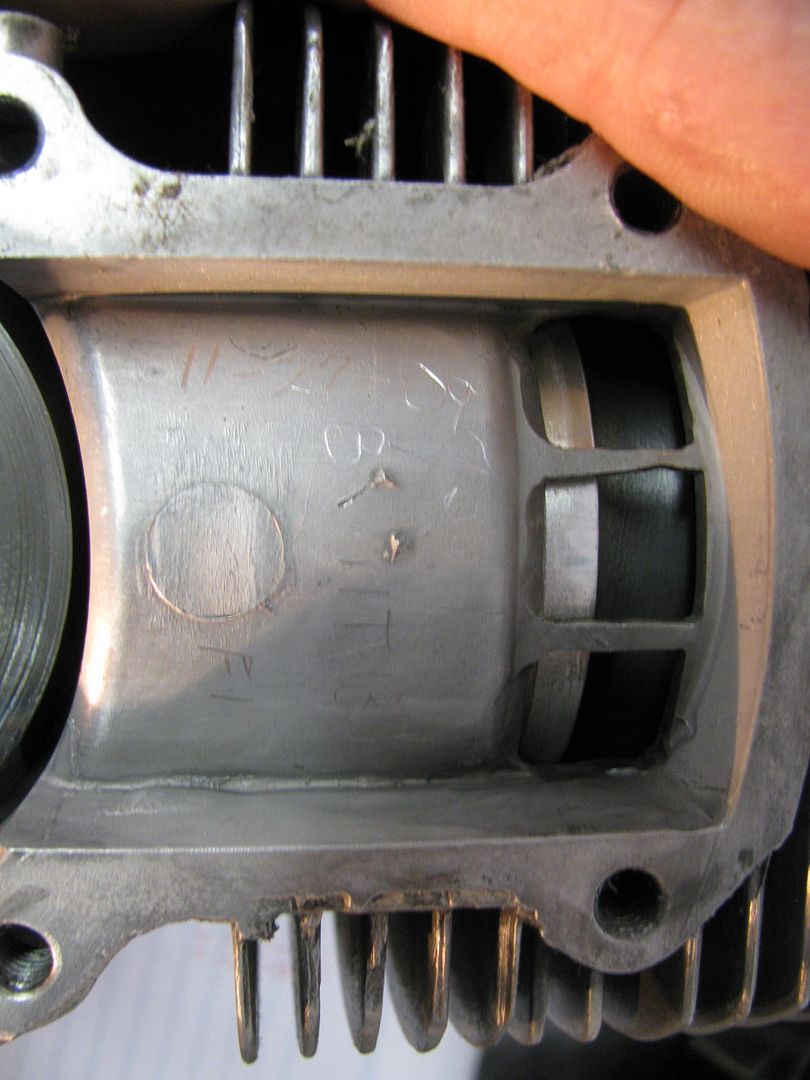

Still tearing the 580 down, I just pulled the intake off and was washing it out so it would be cleaner when coming apart, The crankshaft is a weighted one but thats about all I see so far.

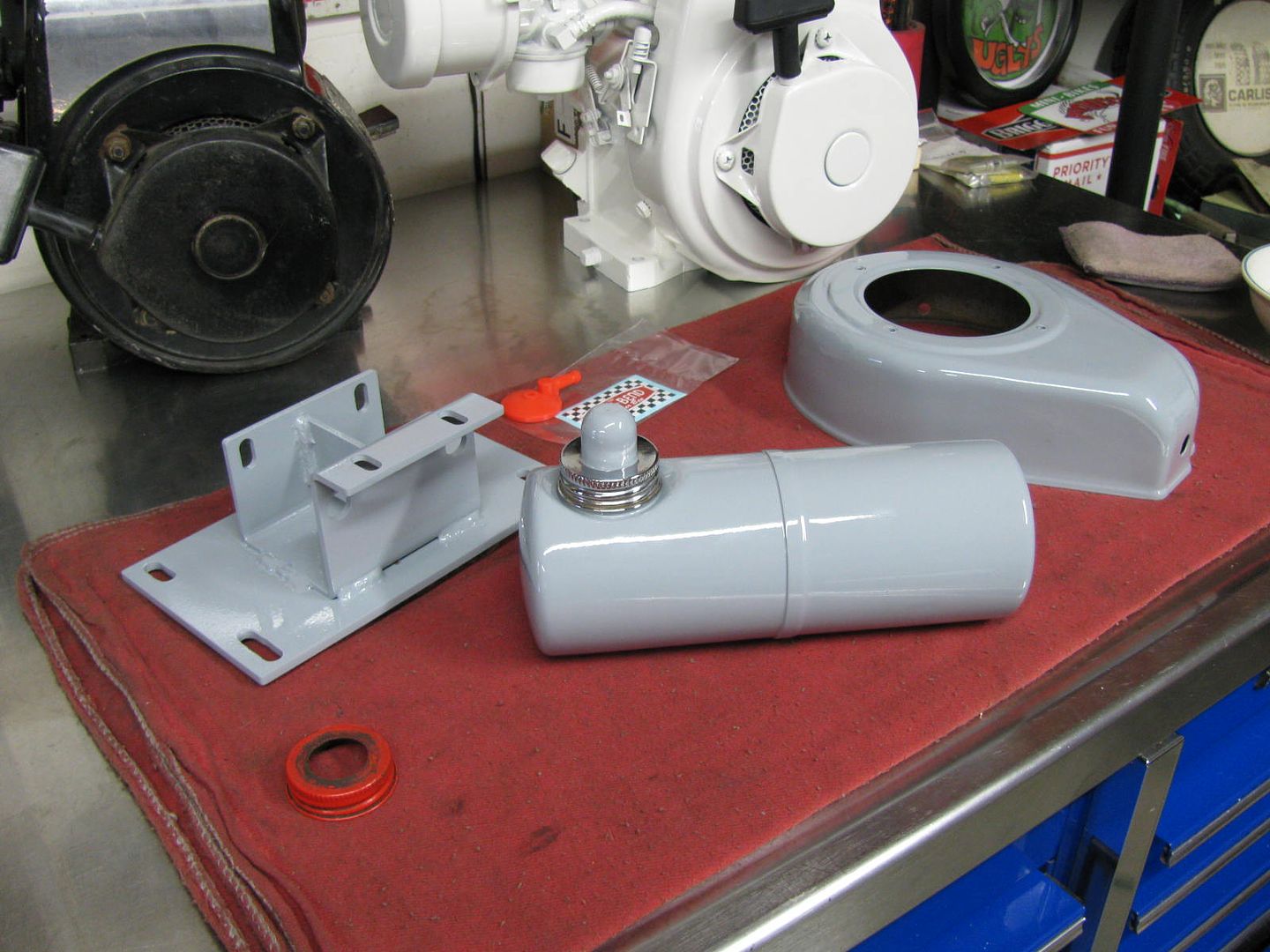

Any insight to the goods/bads of using a stuffer/intake like this, My 700 will be coming apart to be cleaned and inspected cause its been sitting around for awhile and time has come to get that bike buttoned up and running, I like the looks of the intake (its polishing out pretty nice) but the 700 runs very well as it is so I dont want to mess up a good thing!!

Anyone ever heard of it, and whats it gonna do for me as opposed to what appears to be stock offset intake/reed setup I have on a 700?

Still tearing the 580 down, I just pulled the intake off and was washing it out so it would be cleaner when coming apart, The crankshaft is a weighted one but thats about all I see so far.

Any insight to the goods/bads of using a stuffer/intake like this, My 700 will be coming apart to be cleaned and inspected cause its been sitting around for awhile and time has come to get that bike buttoned up and running, I like the looks of the intake (its polishing out pretty nice) but the 700 runs very well as it is so I dont want to mess up a good thing!!