*Should read "An amateur's high compression Mod 2 Hemi build."

I've yet to do an engine build thread, because some of these guys like Ole4, Trinik and a few others, just make me feel stupid. I try reading threads, but often get lost and or bored with all the technical jargon and mathematics. I feel like a hack in comparison, a tinkerer... Yet my motors have proven to be pretty fast and reliable so far. I'm building this motor for my buddy Jose who supplied the practically new Hemi and some gently used parts he got for a steal locally. He brought me, a stock length ARC billet rod, an ARC billet flywheel, a Mod 2 cheater cam and some 18lb Hemi springs.

I talked him into buying a milled Hemi head and some shorter Molly pushrods from my buddy Dan at Childish Concepts Racing.

This Hemi head was milled .075 but is otherwise stock. The NR racing chromoly pushrods are 5.440 in length...

I replaced the bearing inserts in the ARC rod and knocked the governor gear off the crank.

I replaced the bearing inserts in the ARC rod and knocked the governor gear off the crank.

To my benefit, this Hemi crank won't require much clearancing for the cam if any at all. My Hemi was a different story...

Due to my lack of proper measuring equipment, I use plasti-gauge to check for bearing clearances.

A shade on the loose side (just between .051-.076) after torquing the cap and rod to the crank at 170 inch pounds, but everything is new, and nothing can be done about it really, so I'm running with it.

Since it's a new engine, I left the factory piston in it's hole and carefully worked around it as to not disturb the rings. I pulled out and installed the billet rod through the bottom...

Since it's a new engine, I left the factory piston in it's hole and carefully worked around it as to not disturb the rings. I pulled out and installed the billet rod through the bottom...

I then used my angle grinder and small carbide bit to open up the lower hole on the left in the .010 metal head gasket to fit the larger dowel pin on the Hemi block.

Then torqued the milled Hemi head to the block at 19 foot pounds and installed some used 22lb springs from my blown Grayhound clone instead of my buddies supplied 18's.

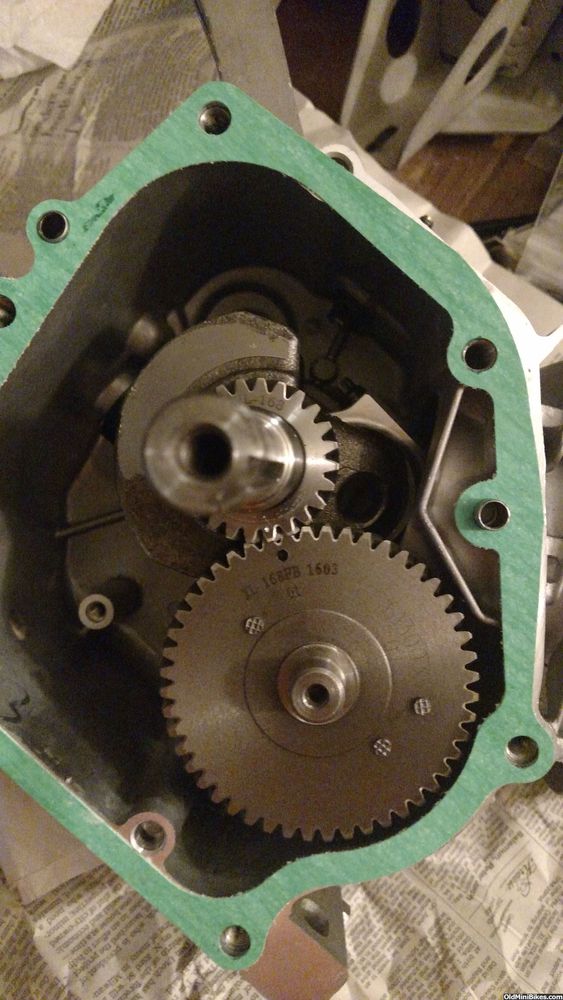

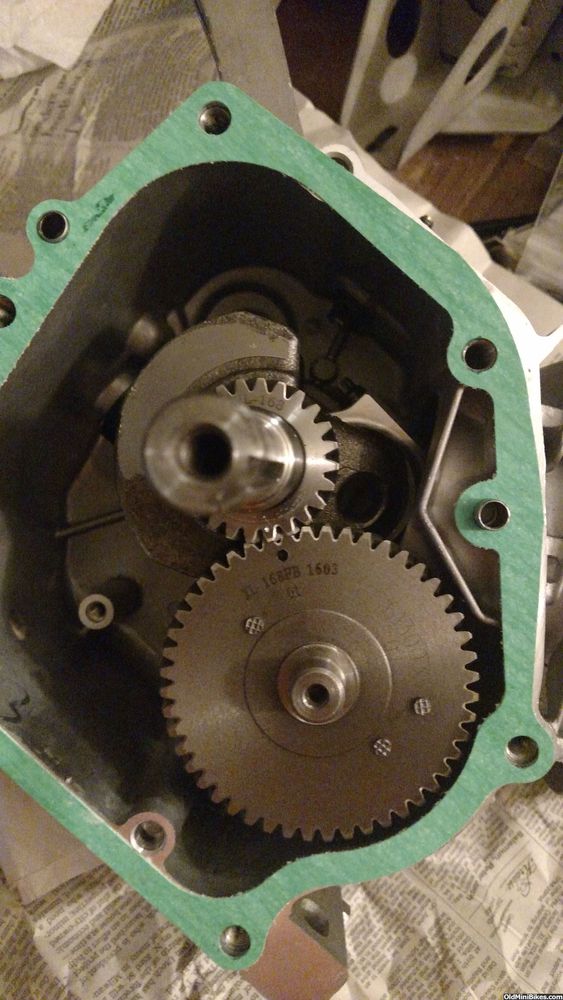

I then inserted the Mod 2 cam in it's position at TDC before putting the sidecover back on

I then inserted the Mod 2 cam in it's position at TDC before putting the sidecover back on

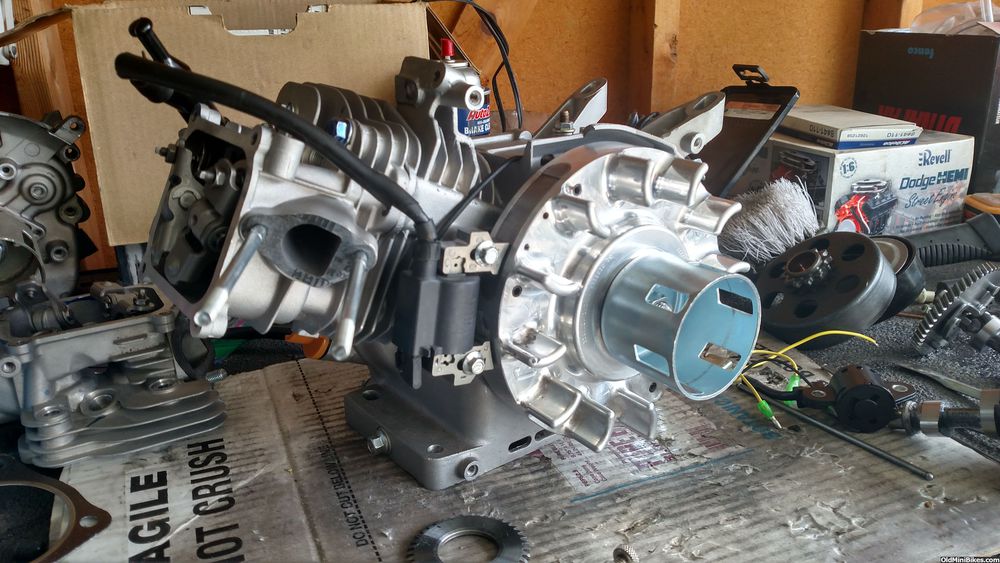

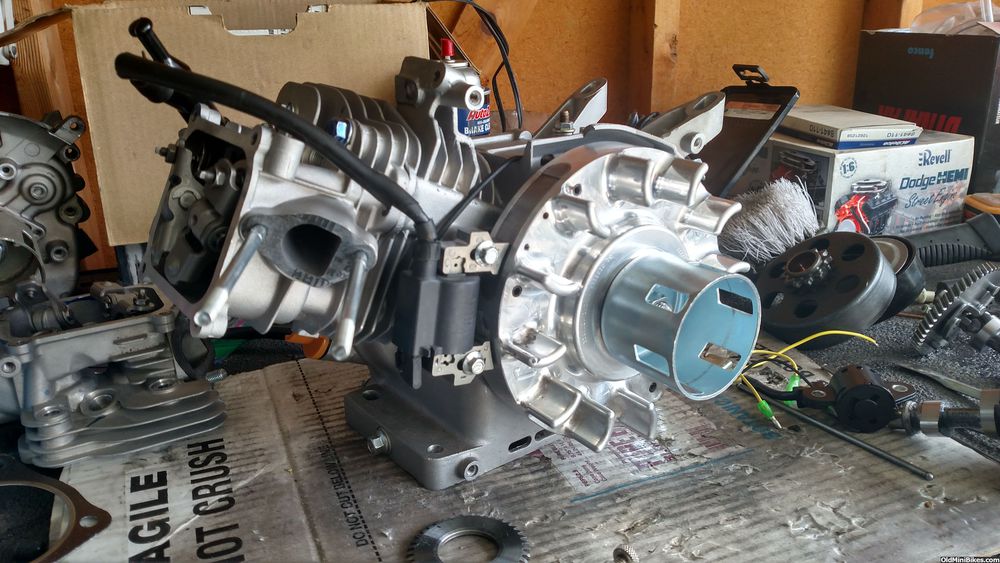

and installing the ARC billet flywheel.

and installing the ARC billet flywheel.

I set coil gap around .040, doubling up .019 & .020 feeler guages and set valve lash at .002 then checked it all again after turning the motor over by hand twice. Tomorrow I will finish buttoning it up and run it. Try to include a little video...

I set coil gap around .040, doubling up .019 & .020 feeler guages and set valve lash at .002 then checked it all again after turning the motor over by hand twice. Tomorrow I will finish buttoning it up and run it. Try to include a little video...

I've yet to do an engine build thread, because some of these guys like Ole4, Trinik and a few others, just make me feel stupid. I try reading threads, but often get lost and or bored with all the technical jargon and mathematics. I feel like a hack in comparison, a tinkerer... Yet my motors have proven to be pretty fast and reliable so far. I'm building this motor for my buddy Jose who supplied the practically new Hemi and some gently used parts he got for a steal locally. He brought me, a stock length ARC billet rod, an ARC billet flywheel, a Mod 2 cheater cam and some 18lb Hemi springs.

I talked him into buying a milled Hemi head and some shorter Molly pushrods from my buddy Dan at Childish Concepts Racing.

This Hemi head was milled .075 but is otherwise stock. The NR racing chromoly pushrods are 5.440 in length...

To my benefit, this Hemi crank won't require much clearancing for the cam if any at all. My Hemi was a different story...

Due to my lack of proper measuring equipment, I use plasti-gauge to check for bearing clearances.

A shade on the loose side (just between .051-.076) after torquing the cap and rod to the crank at 170 inch pounds, but everything is new, and nothing can be done about it really, so I'm running with it.

I then used my angle grinder and small carbide bit to open up the lower hole on the left in the .010 metal head gasket to fit the larger dowel pin on the Hemi block.

Then torqued the milled Hemi head to the block at 19 foot pounds and installed some used 22lb springs from my blown Grayhound clone instead of my buddies supplied 18's.

Last edited: