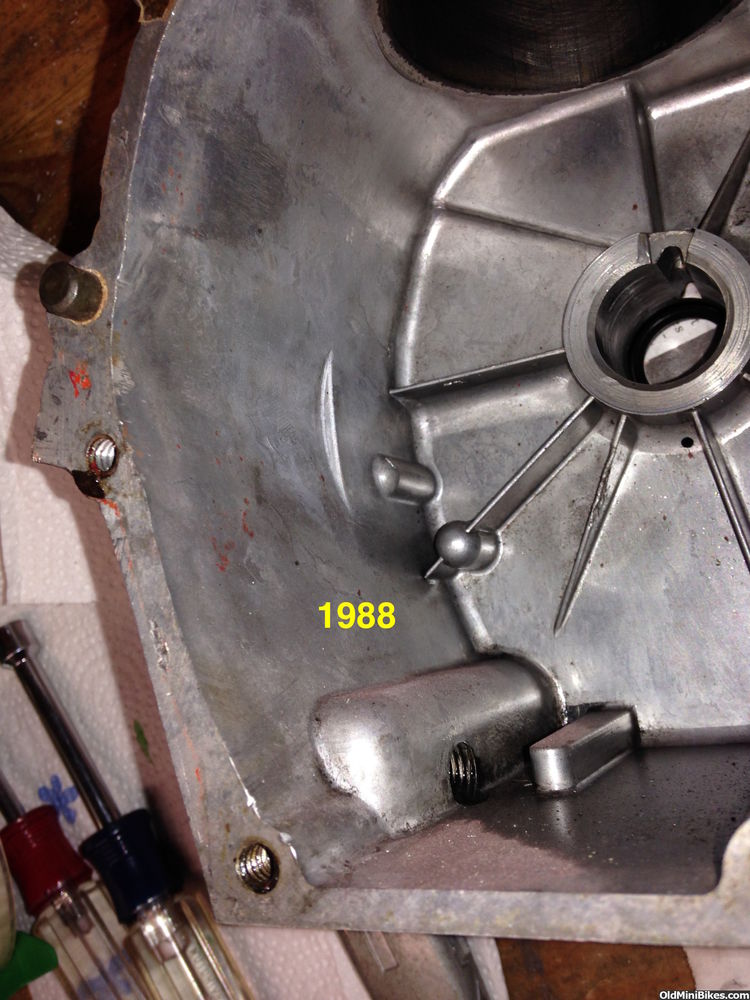

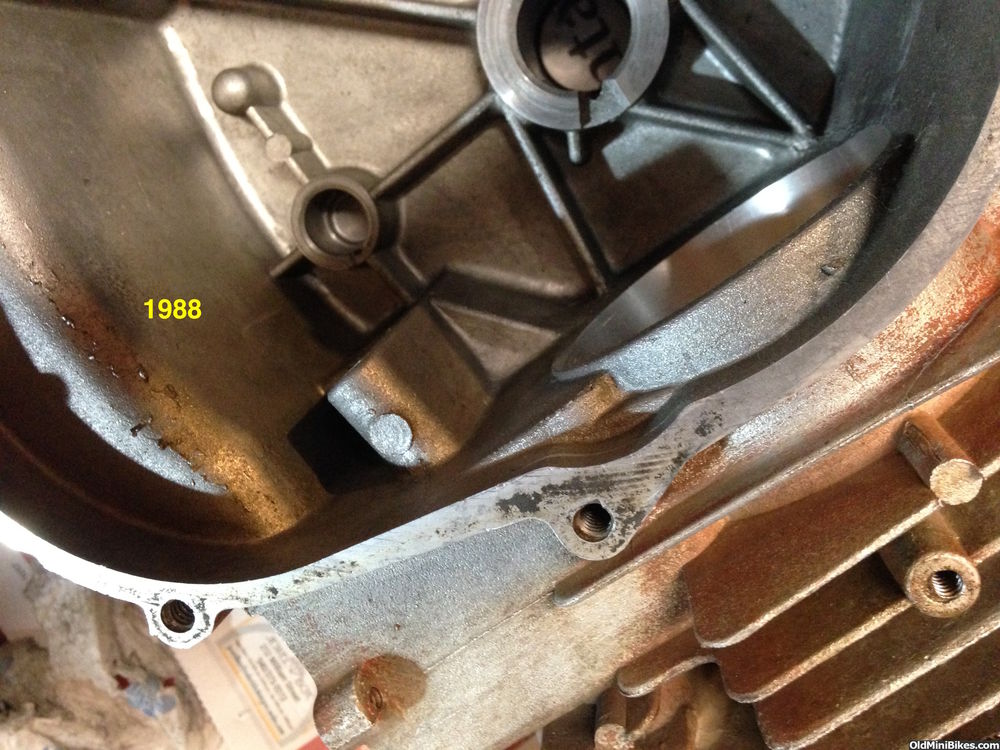

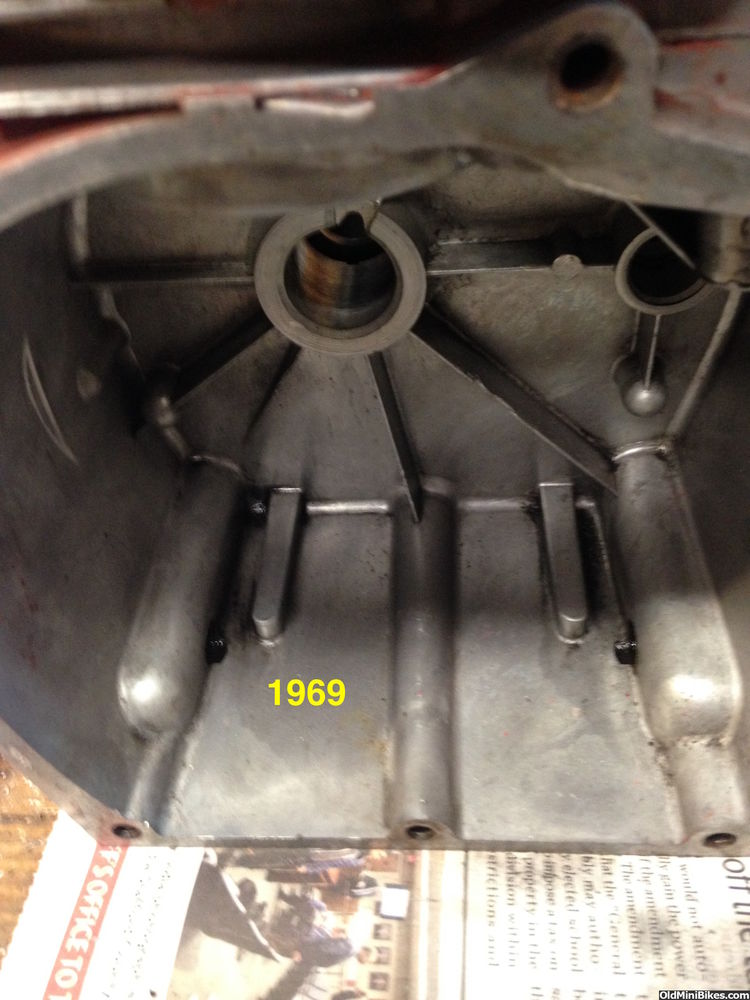

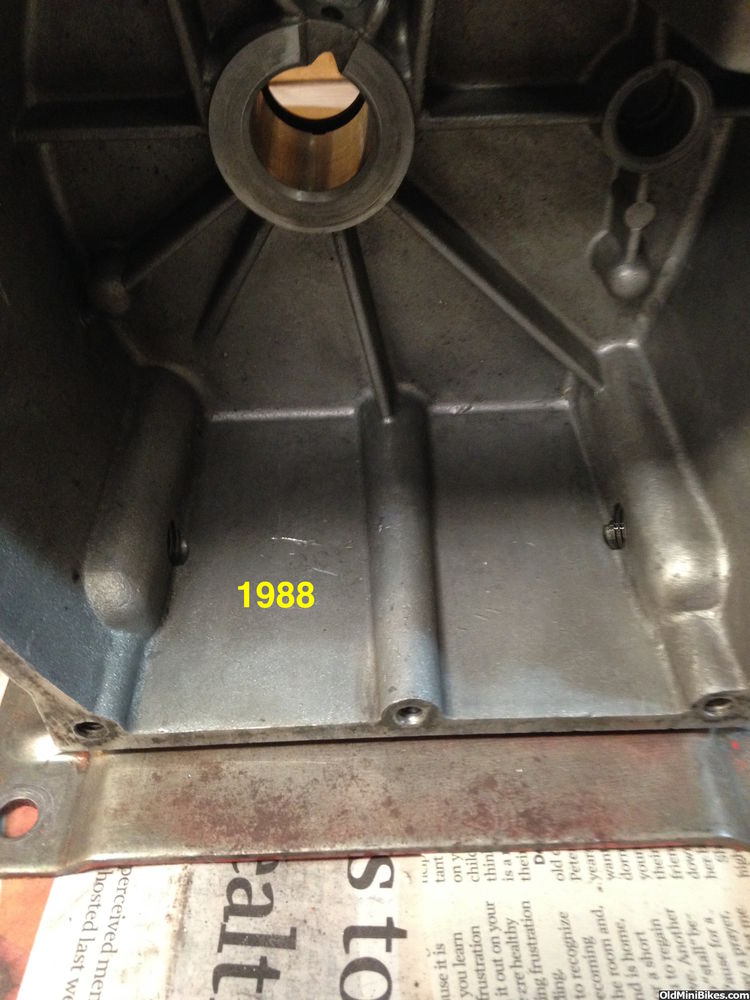

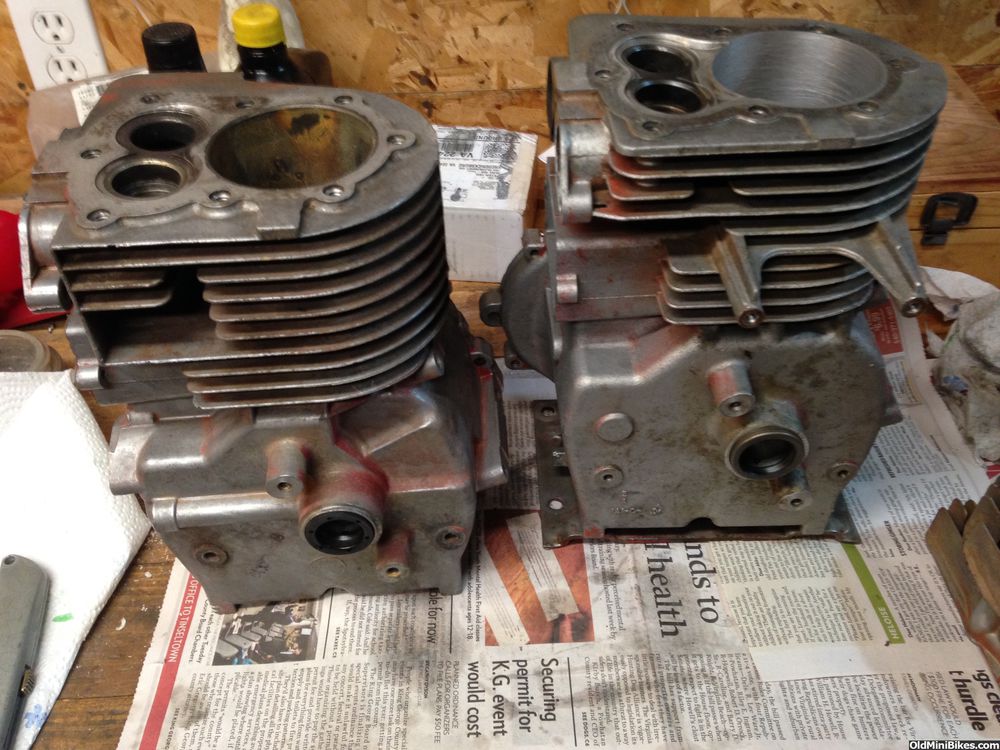

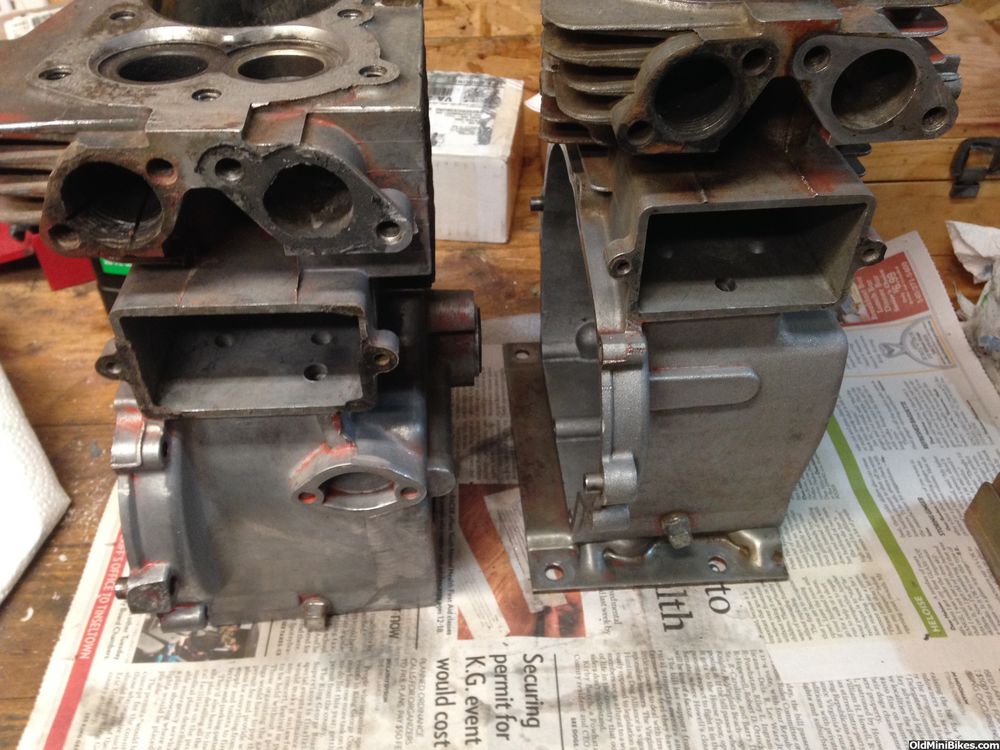

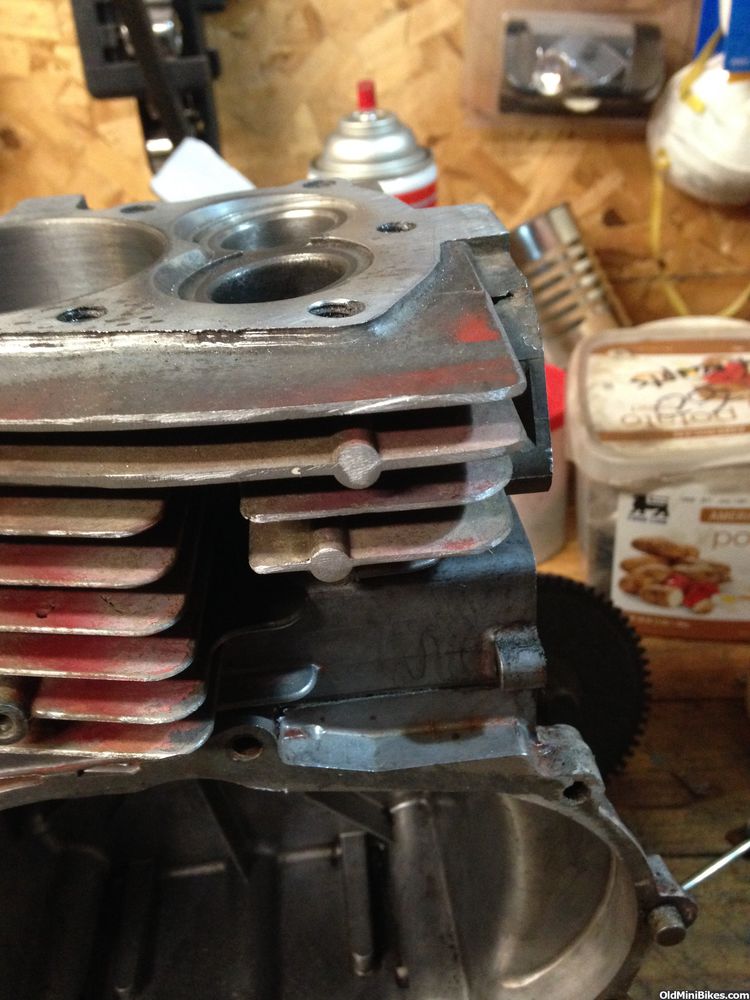

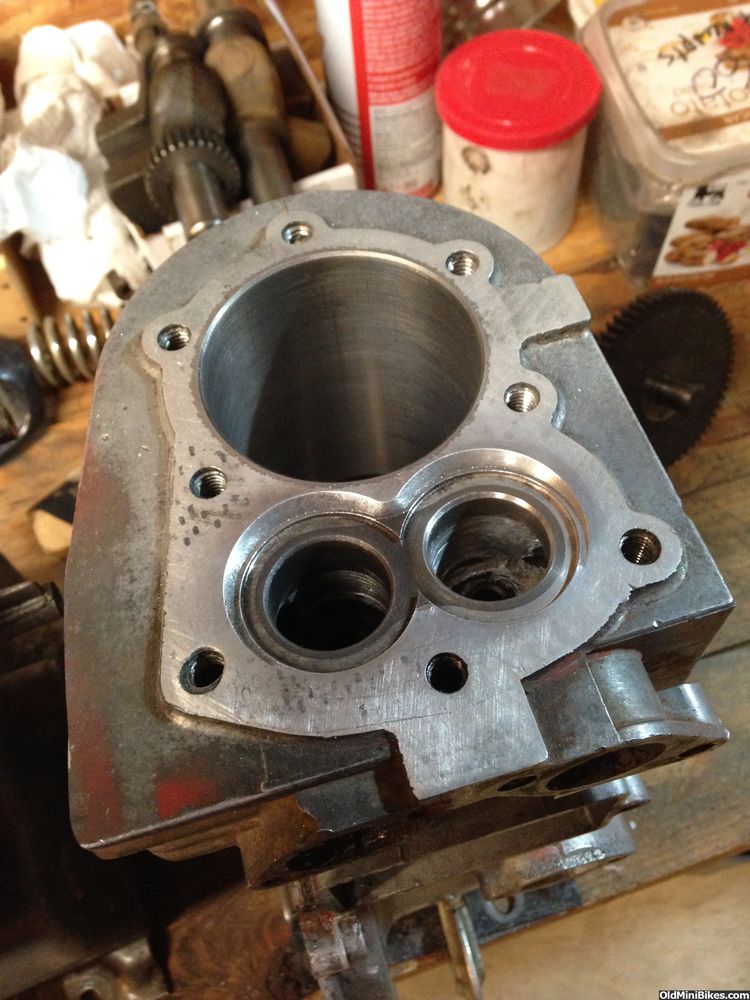

What do you get when you have a tired H60 block that can't be bored 0.020 over? You get Project 14.854 (cubic inches, that is). I'm going to resurrect two H60s--one with a stock bore with new rings and the second bored to accept an H70 piston with an H60 crankshaft. The plan is to build them identically, determine if the H60 carb is effective on both or not, and test them for real world performance. No dynos, no fancy internals.

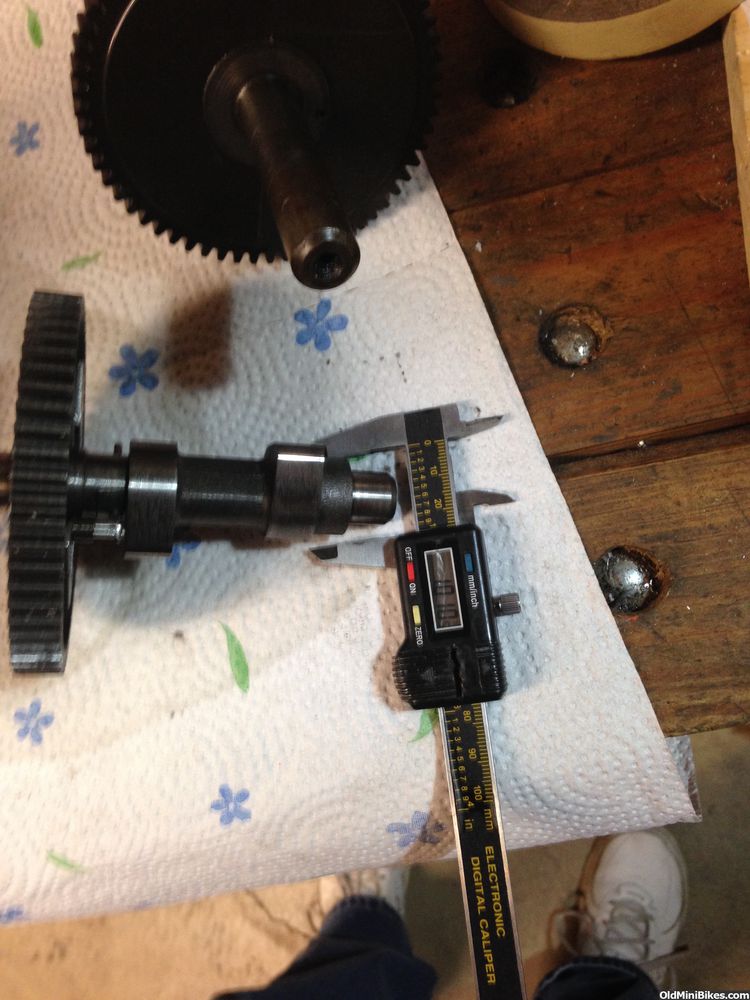

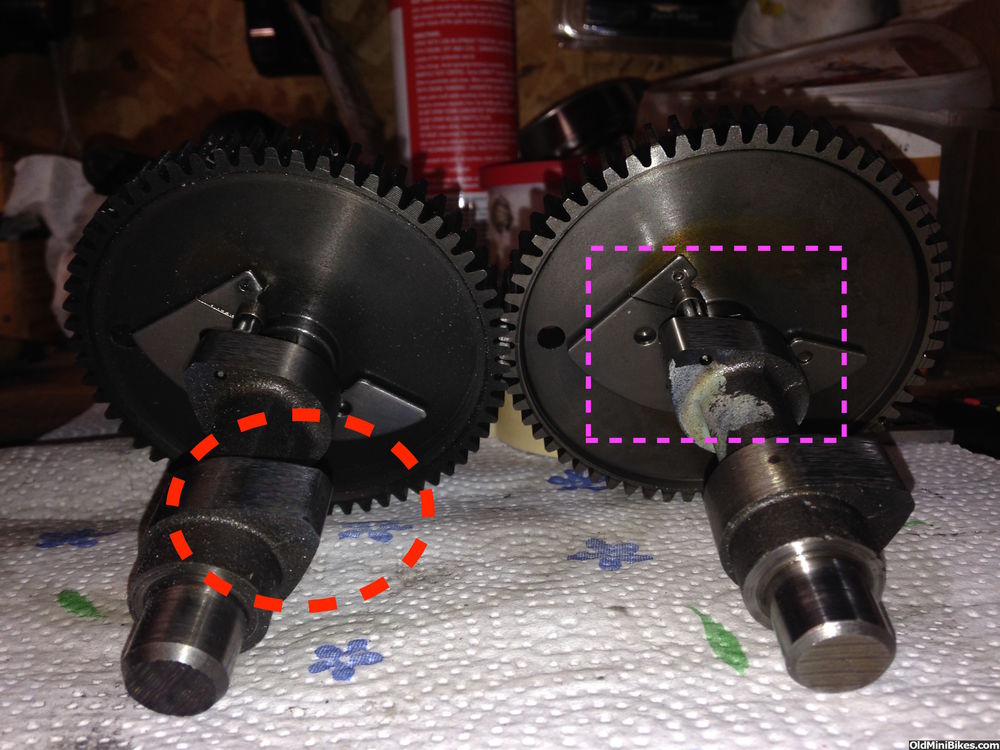

Basically stock and governed. I'm working on now my third H60: Two of the three had the governor spool in pieces. Certainly Project 14.854 suffered from metal and plastic chunks in the crankcase along with over-revving. Hence, the post on how to clean up a crankshaft. I had the engine bored at Steve's Cycle Shop in North Carolina. Found him through eBay and the price was right. He's a mini bike fan, too.

Not as glamorous as the Briggs Raptor v. Tecumseh, but should be interesting. Your input will be gladly accepted. Stay tuned.

Basically stock and governed. I'm working on now my third H60: Two of the three had the governor spool in pieces. Certainly Project 14.854 suffered from metal and plastic chunks in the crankcase along with over-revving. Hence, the post on how to clean up a crankshaft. I had the engine bored at Steve's Cycle Shop in North Carolina. Found him through eBay and the price was right. He's a mini bike fan, too.

Not as glamorous as the Briggs Raptor v. Tecumseh, but should be interesting. Your input will be gladly accepted. Stay tuned.