Tecumseh H50 Stroker

- Thread starter OND

- Start date

I wonder how much material you have on top a stock or over size piston for a H motor? you might be able to had the guy off set the grind little. for example .025 or more out. making it even more of a stroker engine. it would all depend on clearance and the thickness of the top of the piston. clearance would be the rod on how close it gets to the side of the case and maybe camshaft too. i'm sure if it was close you could still take off .025 material and not effect the integrity of the block or camshaft. that would be one crazy stroke out H-motor and with a over size piston.....:thumbsup: just think how much more cc's that would be.

eric would happen to know the rod length would be? and also do you know or anybody know if the last H-motors went to a thin style ring like the small blocks did and ohh-motors.

eric would happen to know the rod length would be? and also do you know or anybody know if the last H-motors went to a thin style ring like the small blocks did and ohh-motors.

Eric???

Evening Pete , and you got me at this point ! I'll probably check the stock ring gap on the old rings first and see how the ring gap is . Usually I'll go over stock .010 or .020 If I can find them , then file fit the gap that I need . Some of the Tec engines (stock) ring gap surprise's me as they are usually quite large by todays standards .

Pete , probably no over size piston in this one , but really I don't know much till the crank gets back . As far as aluminum flywheel I would love to have one ( not ruled out yet )but might be better off with the heavy stock wheel that I have...maybe just maybe it will help it start a little easier . If not I might have to do like you and put an electric starter on it .

Pete , probably no over size piston in this one , but really I don't know much till the crank gets back . As far as aluminum flywheel I would love to have one ( not ruled out yet )but might be better off with the heavy stock wheel that I have...maybe just maybe it will help it start a little easier . If not I might have to do like you and put an electric starter on it .

Last edited:

Evening Pete , and you got me at this point ! I'll probably check the stock ring gap on the old rings first and see how the ring gap is . Usually I'll go over stock .010 or .020 If I can find them , then file fit the gap that I need . Some of the Tec engines (stock) ring gap surprise's me as they are usually quite large by todays standards .

Pete , probably no over size piston in this one , but really I don't know much till the crank gets back . As far as aluminum flywheel I would love to have one ( not ruled out yet )but might be better off with the heavy stock wheel that I have...maybe just maybe it will help it start a little easier . If not I might have to do like you and put an electric starter on it .

Pete , probably no over size piston in this one , but really I don't know much till the crank gets back . As far as aluminum flywheel I would love to have one ( not ruled out yet )but might be better off with the heavy stock wheel that I have...maybe just maybe it will help it start a little easier . If not I might have to do like you and put an electric starter on it .

wow that is quite a bit of lift for a stock cam. I would think with just little porting,timing advance,little stiffer spring,good header and carb,correct gearing that engine would move out good...:thumbsup: no mechanical compression relief on any of the h-motors. not even the newer h-motors. for example late 90's to 2000's I would think that's where you would need help pulling it over and not the stroke or bore size.

kind of curious what you had to pay for the crank grind. I have a guy that can reweld and grind to any size and off set too for $100. I don't think that's to bad of a price...:shrug:

kind of curious what you had to pay for the crank grind. I have a guy that can reweld and grind to any size and off set too for $100. I don't think that's to bad of a price...:shrug:

no mechanical compression relief on any of the h-motors. not even the newer h-motors. for example late 90's to 2000's I would think that's where you would need help pulling it over and not the stroke or bore size.

delray , I'm hoping to do most of this stuff that you posted . :thumbsup:

Pete , thanks for the info on starting, I'm hoping I'm just a little lucky to and this thing doesn't break my arm ..:laugh:

Crankshaft is back along with the new rod bearings . Crank looks good and I'll check some numbers tomorrow.

Pete , thanks for the info on starting, I'm hoping I'm just a little lucky to and this thing doesn't break my arm ..:laugh:

Crankshaft is back along with the new rod bearings . Crank looks good and I'll check some numbers tomorrow.

In the 1st Pic in post 4, what am I looking at? Can't for the life of me figure it out.

He then used that number to ascertain how much he needed taken off of the crank journal sides to accommodate the new, thicker, billet rods, but still have some free play so as not to bind.

He's measuring the stock rod (cap) width, and comparing that with what Tecumseh designed on the crankshaft journal to arrive at a theoretical allowance of free play as originally intended. (Side to side slop if you will)

He then used that number to ascertain how much he needed taken off of the crank journal sides to accommodate the new, thicker, billet rods, but still have some free play so as not to bind.

He then used that number to ascertain how much he needed taken off of the crank journal sides to accommodate the new, thicker, billet rods, but still have some free play so as not to bind.

H50 crank shaft in the front and H60 crank shaft in the rear . You can see how the rear rod journal was opened up to.970 width and you guys with eagle eyes can see the rear rod journal is turned down to .998 . I have to admit that these guys at Crankshaft Craftsmen did an excellent job and there numbers were dead on .

One of the billet rods beside the stock H50 rod .

Rod bearings from ARC , 6392 and a 6392-0 . Locked up one billet rod in the vice to measure bearing clearances installed rod cap and bearing and torqued them down , Installed each set of new bearings the same way and the 6392 came out with .003 clearance and the 6392-0 came out at about .005 to.006 . Went back with plastigage and rechecked and came out with the same numbers .

6392 : .003

6392-0 : .005 to .006

Sorry all pics did not come out good, so you'll have to trust me on the numbers. Hard to hold a rod cap , plastigage and take a pic at the same time ...:laugh: I will be using the 6392 bearing on this build.

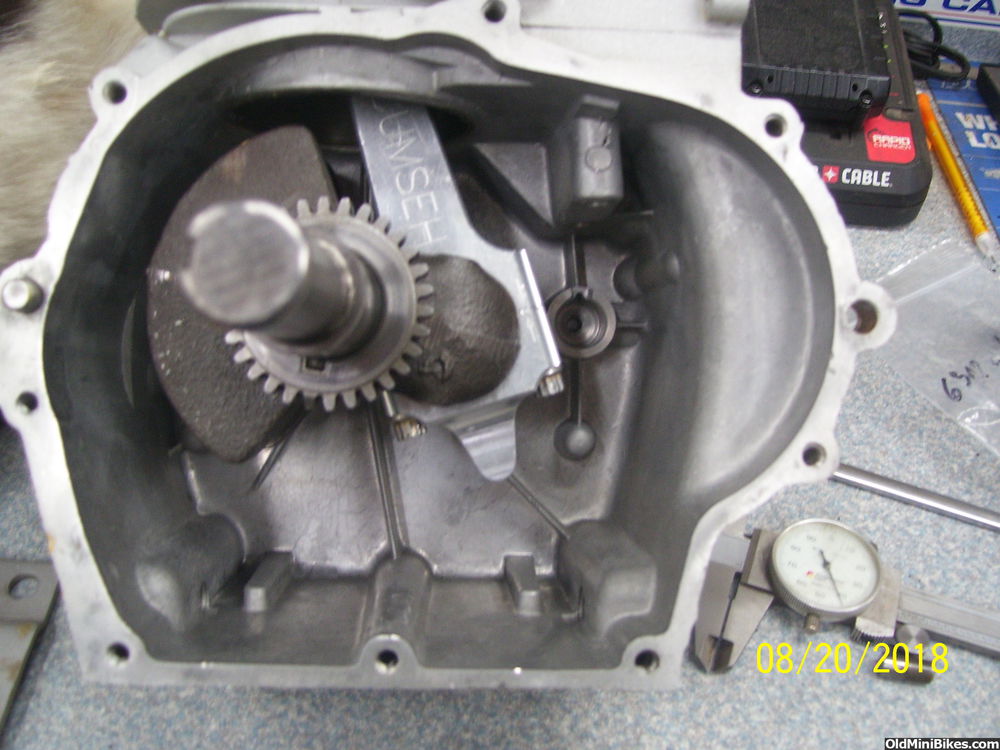

Block has been cleaned and slightly honed for the moment. Dry run on installing the rod and piston, everything looks good at this point.

Up next will probably be the porting , doesn't look real bad Tecumseh did a nice job on these stock ports .

Cam specs , hard numbers are .278 exh and .267 Int . Not sure why the Exh. numbers are higher than the Int. Don't think theres a compression bump on the Exh . But will be doing some more checking though.

Valves measure out the same diameter at 1.155 or about 29mm , not sure why that is either.. Exh. is usually smaller than Int. on most engines.

One of the billet rods beside the stock H50 rod .

Rod bearings from ARC , 6392 and a 6392-0 . Locked up one billet rod in the vice to measure bearing clearances installed rod cap and bearing and torqued them down , Installed each set of new bearings the same way and the 6392 came out with .003 clearance and the 6392-0 came out at about .005 to.006 . Went back with plastigage and rechecked and came out with the same numbers .

6392 : .003

6392-0 : .005 to .006

Sorry all pics did not come out good, so you'll have to trust me on the numbers. Hard to hold a rod cap , plastigage and take a pic at the same time ...:laugh: I will be using the 6392 bearing on this build.

Block has been cleaned and slightly honed for the moment. Dry run on installing the rod and piston, everything looks good at this point.

Up next will probably be the porting , doesn't look real bad Tecumseh did a nice job on these stock ports .

Cam specs , hard numbers are .278 exh and .267 Int . Not sure why the Exh. numbers are higher than the Int. Don't think theres a compression bump on the Exh . But will be doing some more checking though.

Valves measure out the same diameter at 1.155 or about 29mm , not sure why that is either.. Exh. is usually smaller than Int. on most engines.

Last edited:

Looks like you're well on your way. To answer your valve question, I think because this is primarily a big block torque motor (and normally fixed throttle), Tecumseh saw no need to use a smaller exhaust to pull out any more power. What would be interesting is to compare are the valve sizes on the "8 hp" Powersports big block to the 50-70 series family. On my hybrid, piston to rod ratio is 1.1 and it looks like yours is 1.16. I suspect yours is going to rev much more freely than mine does with the added rod length/stock piston.