VERTICAL MOUNTED engine on Mini Bike...?

this subject has came up in the past machinebike,but i dont think you have seen it? with only 31 posting you have,it's been awhile.

with that type of motor and tranny you have,almost have to build a frame setup around it. instead of trying to modify it on to a prebuilt bike frame.

in the future i like to build a atv minibike with a verical motor setup using a tecumseh motor i have and smaller tranny that has forward and reverse.

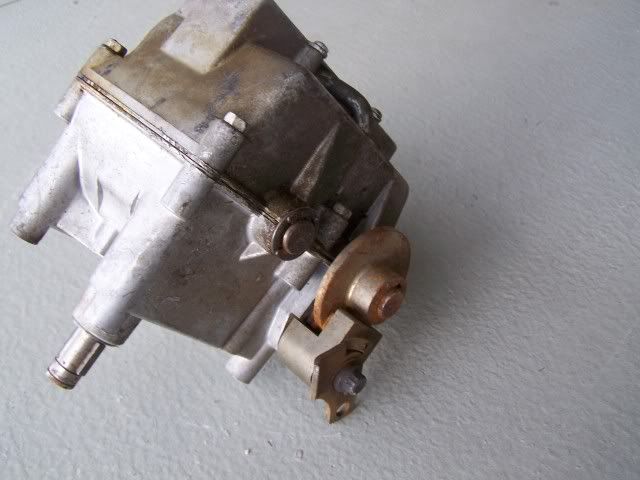

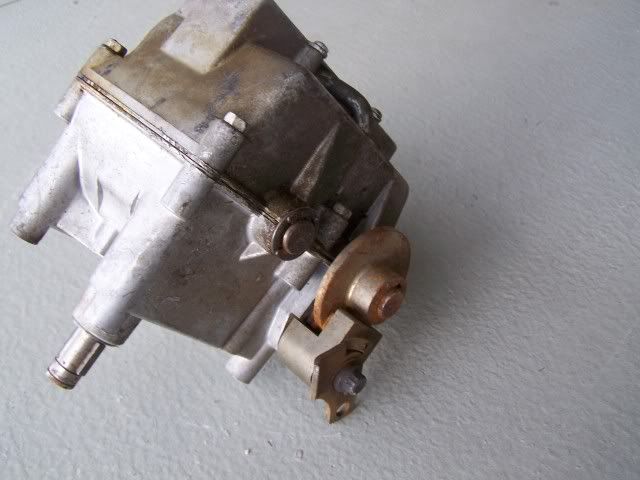

here is the setup that i like to use. it will take less space to mount everything up and for speed i wound think you would only have to change the pulley on the tranny to get the speed you are looking for:thumbsup:

with that type of motor and tranny you have,almost have to build a frame setup around it. instead of trying to modify it on to a prebuilt bike frame.

in the future i like to build a atv minibike with a verical motor setup using a tecumseh motor i have and smaller tranny that has forward and reverse.

here is the setup that i like to use. it will take less space to mount everything up and for speed i wound think you would only have to change the pulley on the tranny to get the speed you are looking for:thumbsup:

should work but youll have to expeariment with the gearing . im doing the same thing here

http://www.oldminibikes.com/forum/project-logs/4274-tracked-2x2-mini-build.html

http://www.oldminibikes.com/forum/project-logs/4274-tracked-2x2-mini-build.html

another thing to look for if you go with a vertical engine is that most newer engines have a 7/8 shaft. so if you go with a centrifugal clutch pulley unit? they will cost little more then a 3/4 unit. maybe i should say alot more? cheapest i have seen a 7/8 clutch with a B style belt pulley was $80 bucks:doah:

manaul clutch set up would be a cool way to do it also.....

manaul clutch set up would be a cool way to do it also.....

Try and do your gearing after the gearbox.

If you Re-gear before the box, Then the gearbox will be running faster, and wont last as long. They use them in race mowers, However, they clean them out and run gear lube in them. But if you do that you will find that they constantly leak.

You may be fine just running it the way it is though.

Looks good though.

If you Re-gear before the box, Then the gearbox will be running faster, and wont last as long. They use them in race mowers, However, they clean them out and run gear lube in them. But if you do that you will find that they constantly leak.

You may be fine just running it the way it is though.

Looks good though.

Try and do your gearing after the gearbox.

If you Re-gear before the box, Then the gearbox will be running faster, and wont last as long. They use them in race mowers, However, they clean them out and run gear lube in them. But if you do that you will find that they constantly leak.

You may be fine just running it the way it is though.

Looks good though.

If you Re-gear before the box, Then the gearbox will be running faster, and wont last as long. They use them in race mowers, However, they clean them out and run gear lube in them. But if you do that you will find that they constantly leak.

You may be fine just running it the way it is though.

Looks good though.

The hot setup and cure for this problem would be to mount the pulley on the output of the gearbox. If you reverse the input and output of the gearbox and change the mounting position, you'll keep the same internal gearspeed but you'll now have a gearbox that is geared for some high speed becuase you reversed the interal gearing. Use the gearing that's already there to your advantage

The hot setup and cure for this problem would be to mount the pulley on the output of the gearbox. If you reverse the input and output of the gearbox and change the mounting position, you'll keep the same internal gearspeed but you'll now have a gearbox that is geared for some high speed becuase you reversed the interal gearing. Use the gearing that's already there to your advantage

So you would have to mount the box sideways?

Like in the picture above, the shaft at the bottom would need to be rotated to attach to the back wheel. And the shaft that would have originally connected to the back wheel would now connect to the motor.

To check the gearing ratio you would need to spin the shaft at the bottom (input) and check the amount that the output shaft rotates. For example: If it takes three turns of the input shaft to rotate the output shaft one turn you have a 3 to 1 reduction. This would produce high torque and low speed. But if you reverse it you would have a 1 to 3 advantage which would create high speed and low torque because for every one rotation of the motor the back wheel will rotate three times.

if thats a gear reduction box? then he needs to go with a one to one ratio box like i posted and it would be much easyer to dial in your speed with trying different pulley sizes on the bottom of the gear box. trying to modifly his gear box buy turning it around just make thing more harder on you self. almost like making a horz-engine into a vertical engine:doah:............

box holds 90w oil,so i would think it could handle the speeds up to 20-30mph

here's a cool box with two speeds forward and reverse and a disc brake on the side.

box holds 90w oil,so i would think it could handle the speeds up to 20-30mph

here's a cool box with two speeds forward and reverse and a disc brake on the side.

if thats a gear reduction box? then he needs to go with a one to one ratio box like i posted and it would be much easyer to dial in your speed with trying different pulley sizes on the bottom of the gear box. trying to modifly his gear box buy turning it around just make thing more harder on you self. almost like making a horz-engine into a vertical engine:doah:............

My point was you already have a gearbox so orient it to your advantage instead of trying to fight it. So a box that may handle 20-30mph could be used at 40-60mph if it were reversed without any additional stress on it.

OriginalWhitey,my question would be? if you could reverse a 3to1 ratio so it had top end. wouldn't be kind of hard to make it have low end to take off easy and still have your top end. maybe for me and you it would easy to machine or fab the end of the shafts from a sprocket to a pulley shaft, but for some it could be a problem:hack::hammer::weld:

my 2-speed tranny would cool to use in a project. bike could be set up where you would use pulleys and a belt with a idler pulley that could disengage with a foot pedel. allowing the engine speed to come down,so you could shift it on the fly.........

my 2-speed tranny would cool to use in a project. bike could be set up where you would use pulleys and a belt with a idler pulley that could disengage with a foot pedel. allowing the engine speed to come down,so you could shift it on the fly.........