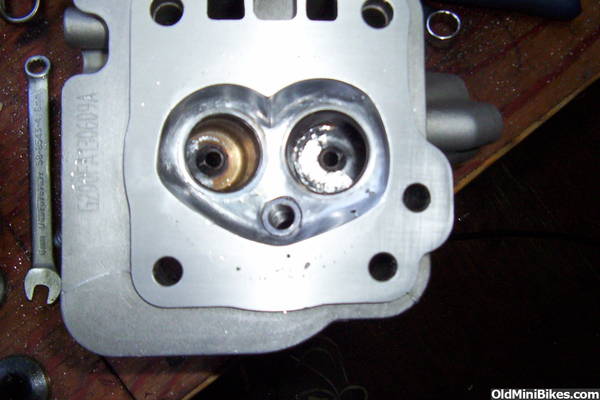

Porting and test fit of the intake bowl insert.

I am plowing ahead with this but this insert is kind of shallow and i think I need some thicker aluminum.

But here's a view of what I have so far.

You can just make out the insert sitting here.

If it werew a bit thicker it would make for a better transition from the runner floor to the back of the bowl.

Without a flow bench is impossible to say what kind of real flow effect this will have.

This is all just a crap shoot based on a hunch.

There is so much I just don't know about this head.

Like how far I can pull the bowl down for starters.

I am plowing ahead with this but this insert is kind of shallow and i think I need some thicker aluminum.

But here's a view of what I have so far.

You can just make out the insert sitting here.

If it werew a bit thicker it would make for a better transition from the runner floor to the back of the bowl.

Without a flow bench is impossible to say what kind of real flow effect this will have.

This is all just a crap shoot based on a hunch.

There is so much I just don't know about this head.

Like how far I can pull the bowl down for starters.