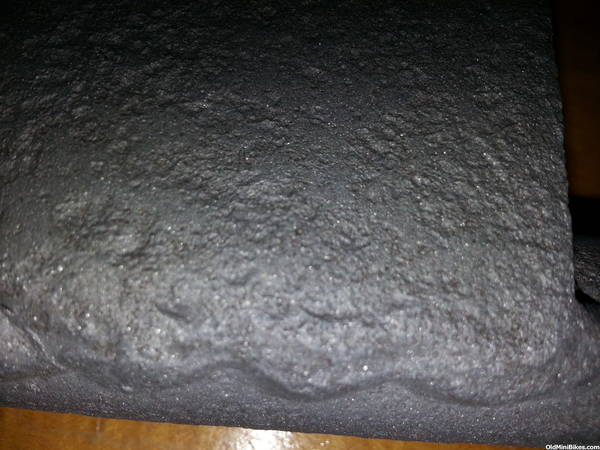

How best to fill in this kind of frame erosion?

One of the powdercoating guys here (Texaspowdercoater?) said to use JB weld to fair the metal, as it will hold up to the baking.

One of the powdercoating guys here (Texaspowdercoater?) said to use JB weld to fair the metal, as it will hold up to the baking.

It will be ok for powder then.:thumbsup:

blast clean like you have, then wipe with acetone, then apply the jb (red and white original formula, not the 4 hr quick dry type, I find it (4hr) doesnt seem to like the bake cycle so much). Smooth it on there with a stiff card that will wrap around the pipe a bit, then smooth it on and let it sit, then sand like any other filler.

It will be ok for powder then.:thumbsup:

It will be ok for powder then.:thumbsup:

blast clean like you have, then wipe with acetone, then apply the jb (red and white original formula, not the 4 hr quick dry type, I find it (4hr) doesnt seem to like the bake cycle so much). Smooth it on there with a stiff card that will wrap around the pipe a bit, then smooth it on and let it sit, then sand like any other filler.

It will be ok for powder then.:thumbsup:

It will be ok for powder then.:thumbsup:

You are correct. The JB Kwik Weld has a lower melting point than the regular JB Weld. Ogy

(Moistened finger= spit) :laugh:

For paint, you could try filler primer after acetone, or boat products like West 404 mixed with polyester resin. (or talcum powder) I've found it sticks real well to prepped metal.

blast clean like you have, then wipe with acetone, then apply the jb (red and white original formula, not the 4 hr quick dry type, I find it (4hr) doesnt seem to like the bake cycle so much).

I wasnt aware of that (the lower melt point on the JB quick) We use it in all kinds of heat situations but I've never actually "baked" it. Good to know.

I wasnt aware of that (the lower melt point on the JB quick) We use it in all kinds of heat situations but I've never actually "baked" it. Good to know.

What is it

Show the hole bike please

Is it worth the effort ?

I'll fix anything where there's a will there's a way!

That could be fixed

If your worried about the engine plate either cut it off or make a new copy and weld it to it.

Where u from

are u able to weld the plate in?

Fill the frame bars with filler and prime to paint

Show the hole bike please

Is it worth the effort ?

I'll fix anything where there's a will there's a way!

That could be fixed

If your worried about the engine plate either cut it off or make a new copy and weld it to it.

Where u from

are u able to weld the plate in?

Fill the frame bars with filler and prime to paint

blast clean like you have, then wipe with acetone, then apply the jb (red and white original formula, not the 4 hr quick dry type, I find it (4hr) doesnt seem to like the bake cycle so much).

I wasnt aware of that (the lower melt point on the JB quick) We use it in all kinds of heat situations but I've never actually "baked" it. Good to know.

I wasnt aware of that (the lower melt point on the JB quick) We use it in all kinds of heat situations but I've never actually "baked" it. Good to know.