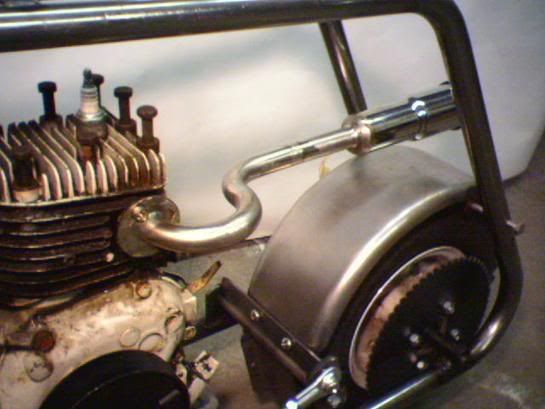

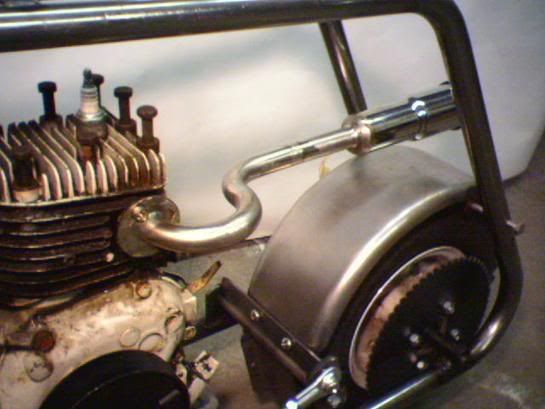

water pipe welded to the stock flange. it's got an Ace Hardware replacement muffler i can take on and off. i also stuck some header wrap on it for the hell of it. without the muffler it's very loud.

i think i'm going to get rid of it and buy a header for it instead.

if you didn't notice yet, it's not actually mounted and is just sitting behind the motor in the pic. i was in the middle of painting all the tins.

i think i'm going to get rid of it and buy a header for it instead.

if you didn't notice yet, it's not actually mounted and is just sitting behind the motor in the pic. i was in the middle of painting all the tins.

Last edited:

hayden,you maybe want to just purchase a oversize washer(large) that has the correct hole size for your pipe and then just drill two holes for the bolt flange. type of washer i am talking about are 1/8 thick(big). you can get them in stainless if you want to run the whole exhaust system in stainless or just galvanize will work good too for reg steel. just make sure you grind some of the galvanize off little before welding it together:thumbsup:.

here's couple different exhaust using a thick oversize washer for a header flange. for my pipe thickness i been using 18g and 16g. 16g maybe little over kill:doah:but it does make things easyer for me to weld everything up:weld:

here's couple different exhaust using a thick oversize washer for a header flange. for my pipe thickness i been using 18g and 16g. 16g maybe little over kill:doah:but it does make things easyer for me to weld everything up:weld:

This is one I came up with on a go-cart I did for my daughter last year. I welded up the frame and didn't measure behind the engine so it was one of those born of necessity things. It's a 1/8 flange I cut down, electrical conduit for the bend and exaust couplers from Advanced auto. I also made a baffle inside with steel wool that helped a little but it's still pretty loud.

click this link things I made just for fun then look at the second picture sorry its so blurry but that bike had some interesting exhausts on those dual animals

click this link things I made just for fun

You made that toucan? The feet must have been a bit@h! Looks nice.

You made that toucan? The feet must have been a bit@h! Looks nice.

thank you I am very proud of how the toucan came out the feet are made of copper wires soldered together the wire is sharpened at the end to make the claws then the legs and feet are wound with thread until they were the correct thickness then they were coated with 5 min. epoxy then painted

.

the body was made by cutting a 1/4 silloette and adding pieces until it was the correct thickness and then it was belt sanded and hand sanded then once it looked right I cut his head off and turned it a little and reglued it and sanded it some more then finally glass fish eyes were hand painted and installed then the whole bird was painted

.

the base was a wood turning project

dont ask me why I did this but in the center of the bird is a real gold coin ut:

ut:

.

the body was made by cutting a 1/4 silloette and adding pieces until it was the correct thickness and then it was belt sanded and hand sanded then once it looked right I cut his head off and turned it a little and reglued it and sanded it some more then finally glass fish eyes were hand painted and installed then the whole bird was painted

.

the base was a wood turning project

dont ask me why I did this but in the center of the bird is a real gold coin

click this link things I made just for fun

You made that toucan? The feet must have been a bit@h! Looks nice.[/QUOTE

That is a very wild drag mini, nice work...

You made that toucan? The feet must have been a bit@h! Looks nice.[/QUOTE

That is a very wild drag mini, nice work...