To think... Less than a year ago last July, I picked up this ARCO Easyrider locally on Craigslist, not knowing shit about it or this amazing hobby we all enjoy. I chose it over a Doodlebug the same guy was selling because I liked it's ratty look and the stretched frame fit my adult size a little better. It had a stock non Hemi Predator in it with a Chinese clutch and the governor disconnected. The throttle was a brake handle and the choke knob was missing. The foot pegs looked homemade and the kickstand and original suspension seat and gas tank were long gone (didn't know at the time)

Now nearly a year later, a few full custom builds, (Including a couple Build-Off bikes) and at least a half dozen riders later, it was time to give the old slut some love...

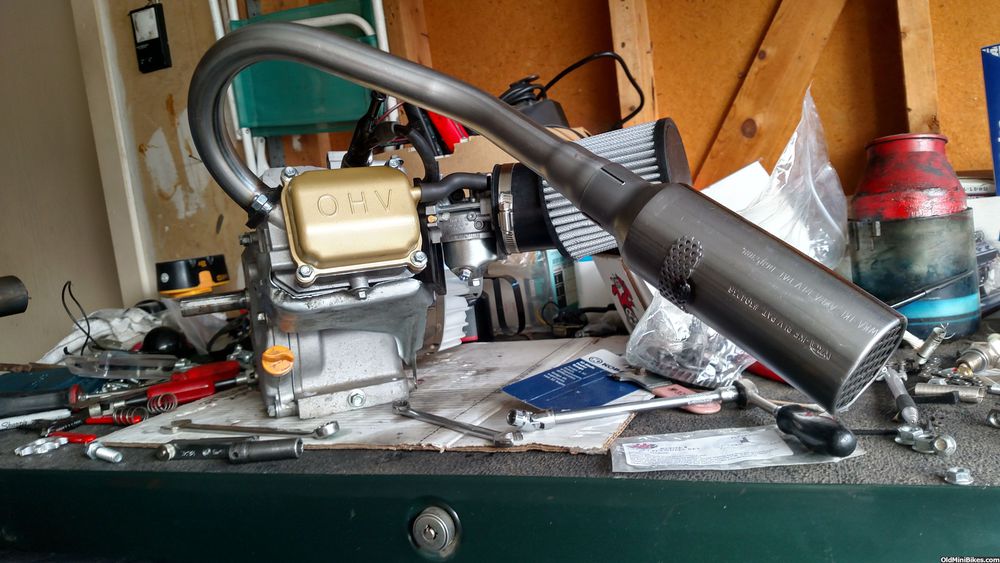

I started like many do with the basics...made my own exhaust

And shaved down some Harley Davidson Sportster foot pegs to fit the frame...

And swapped out the previous owner's brake handle throttle and questionable linkage...

Rode it like that for a few months, but ended up selling the old non Hemi Predator, to put together a brand new Hemi Predator that I had gotten in another deal. The previous owner of the Hemi had installed a Chi-kini carb and ran into financial trouble and sold it and a ton of other parts, bikes and motors before even trying to start it.

I just had to dig up the missing stock parts and re-assemble along with a new re-jetted Ru-xing carb, intake and the exhaust I had made

Rode it like that for about a month or two and when I could no longer wait for new tires, I decided it was time for a mechanical upgrade/restoration.

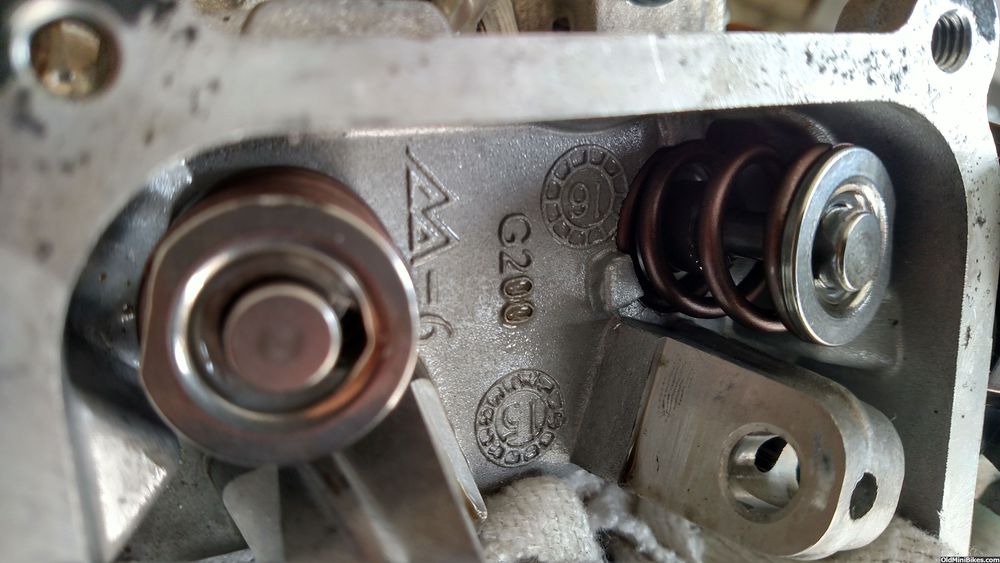

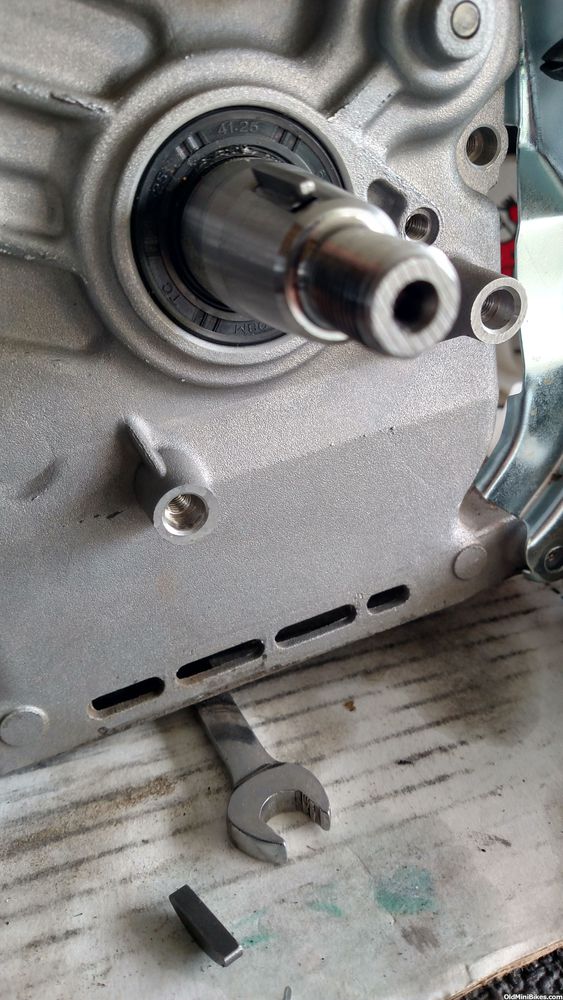

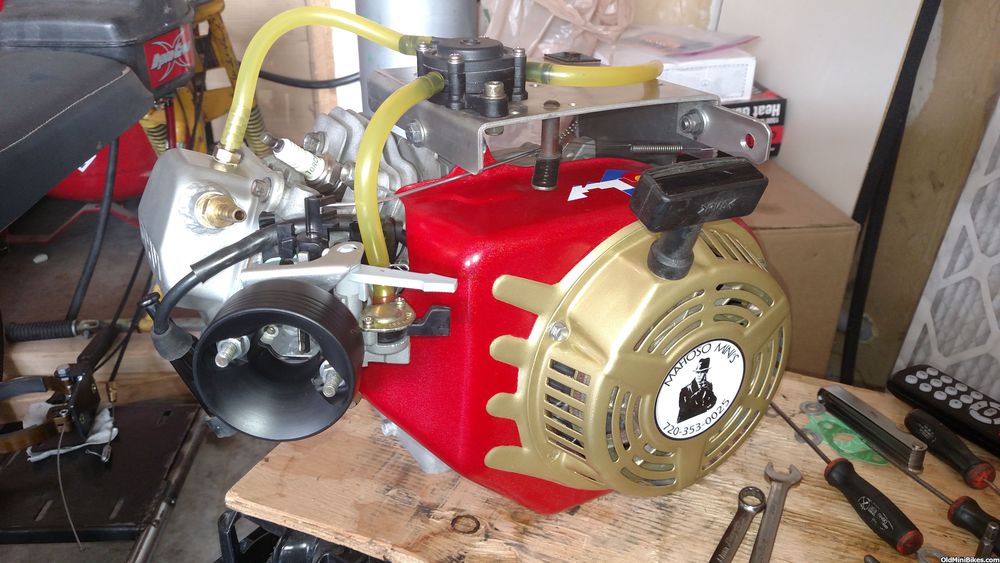

Time for tires, tubes, bearings and some mild goodies for the Hemi Predator. Installing an original CL1 (high torque), 18lb springs made specifically for the Hemi head and an 8° flywheel advance key from ARC racing along with an upsized pilot jet to match the upsized main jet.

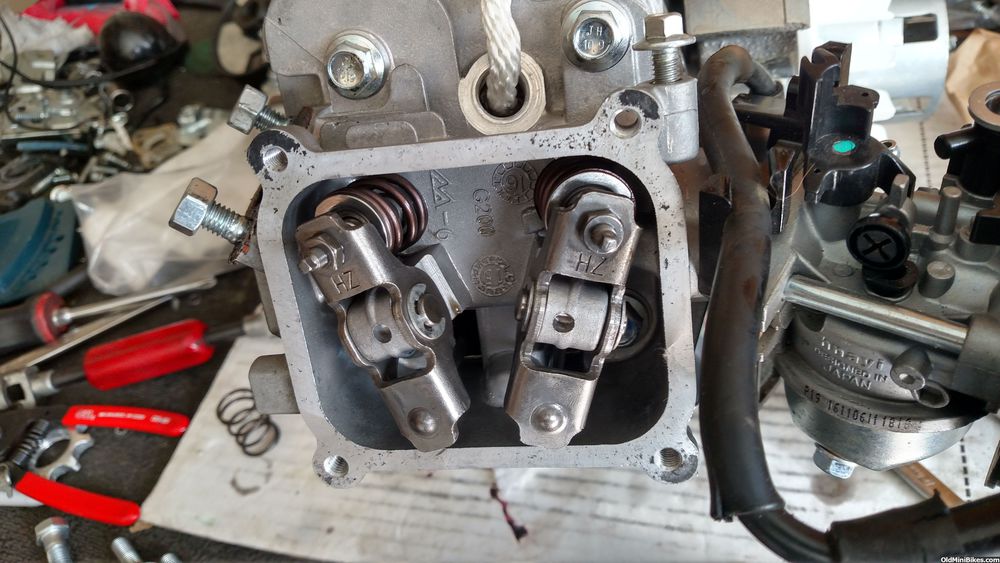

Cam and springs installed. Surprisingly, after removing the c-clips and rockers and installing the springs, I re-assembled as was and had perfect .003 valve lash without any adjustments required.

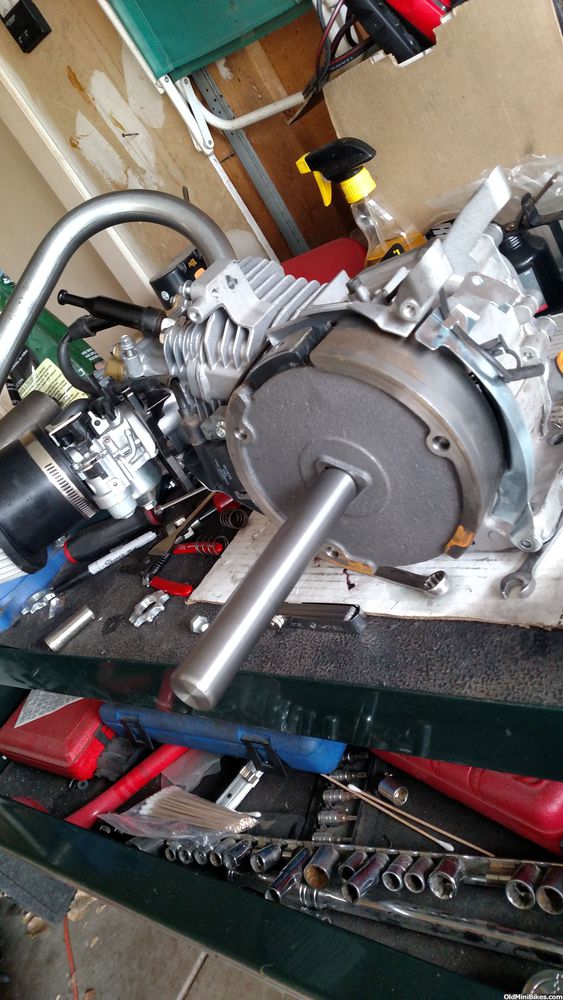

Using a flywheel knocker, I removed the flywheel and installed the 8° advance key. Now before the fun police respond with "you need a billet rod and flywheel!" The CL1 is all done by 6000RPM, and yes I understand you might be gambling in that range, but according to Dyno Cams, I am just crossing the line for a billet flywheel with the upgraded springs and larger open exhaust I'm also putting on it. It won't be near 6k RPM often, and I know a few guys that spin these above 6k regularly, so although flywheel failure is possible, it's not as common as some swear by. Especially under 6k...I will upgrade to a bigger cam when I can afford the extra $200 in billet parts.

with the tin work off, I decided to add some color to the blower housing and valve cover. I also installed the new exhaust and slipped the Mod RLV muffler.

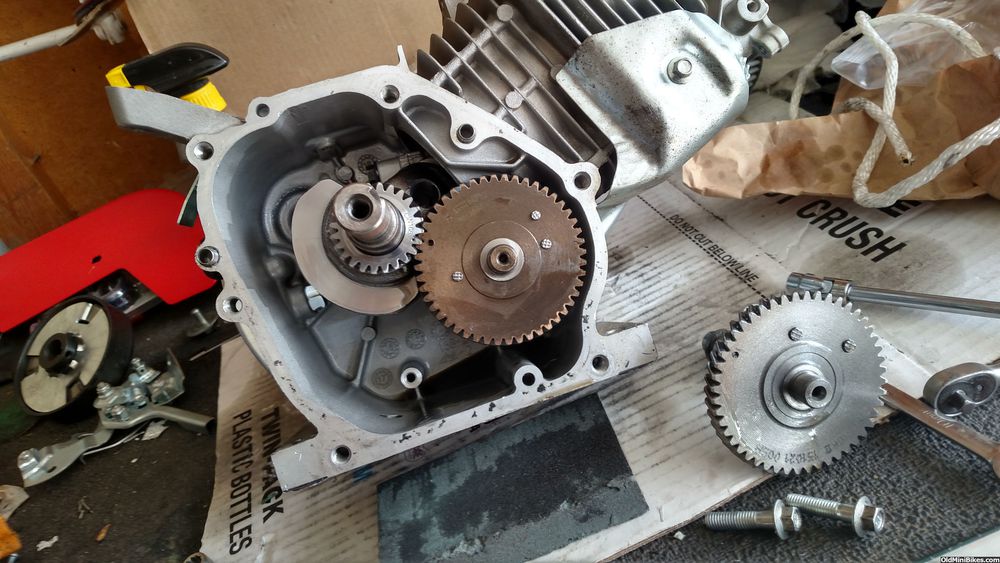

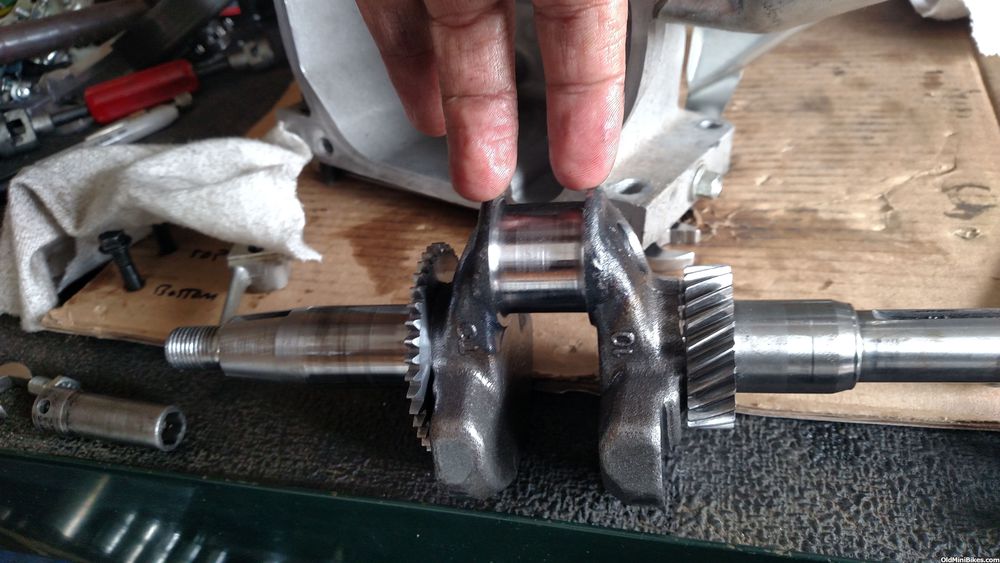

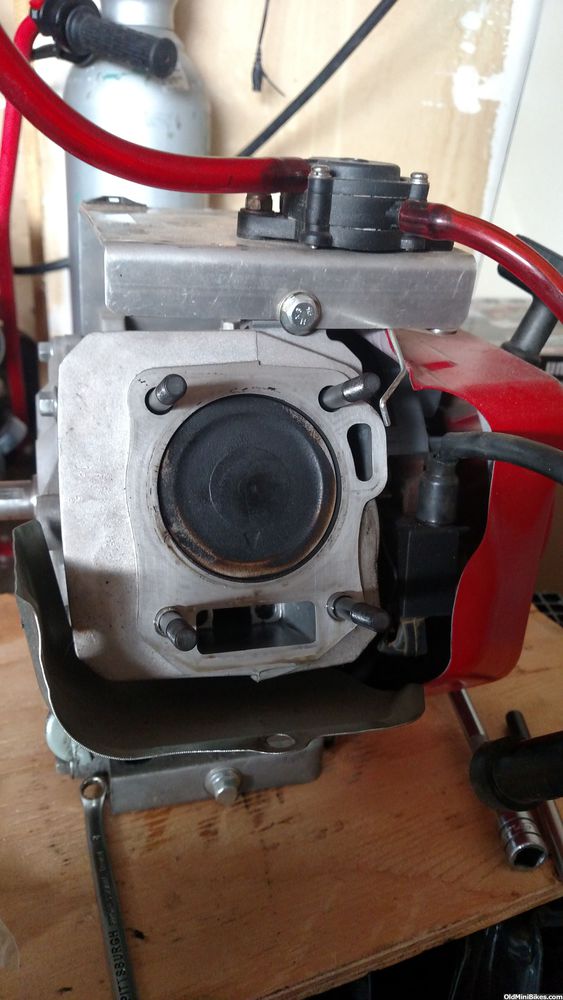

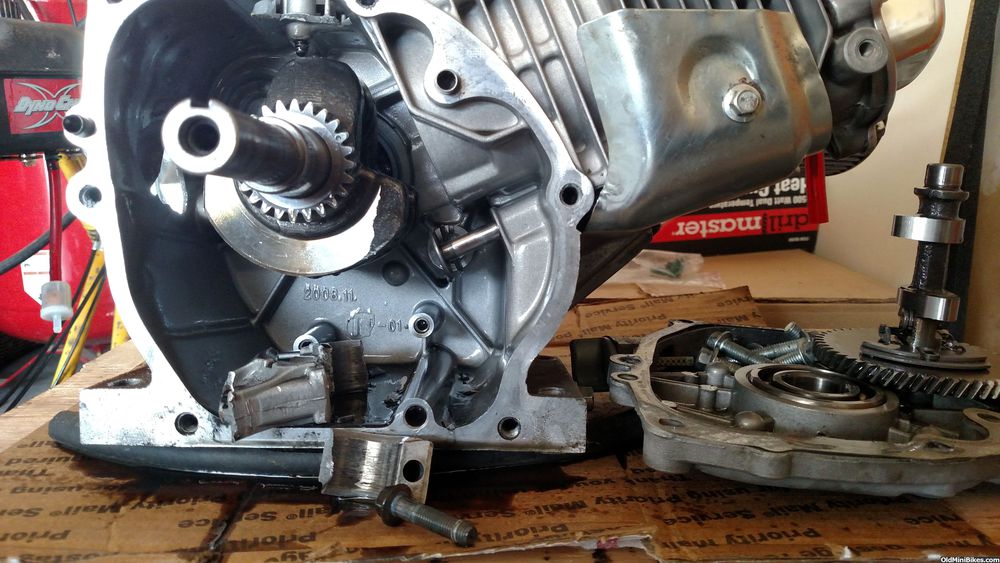

Got it all back together and went to pull it for the first time and on the 2nd pull it tried to fire but had an unusual loud knocking noise. I pulled the pull start back off and pulled out the spark plug and went to turn over the engine by hand. Right around TDC there was a hard spot in the rotation. There was the knock... Damn. I had chosen the CL1 because it was the only cam that didn't have a warning about cam lobe/crankshaft clearance and it's lower RPM range. (using stock parts). With an idea of what was going on I removed the sidecover and could visibly see the exhaust lobe smacking the crank at TDC. Damn it... Was nothing left to do but pull the crank.

These are the areas in question that needs clearancing

One side done

Now this crank should be able to clear just about any camshaft

I also rounded out the knick in the exhaust lobe on the CL1 and re-assembled

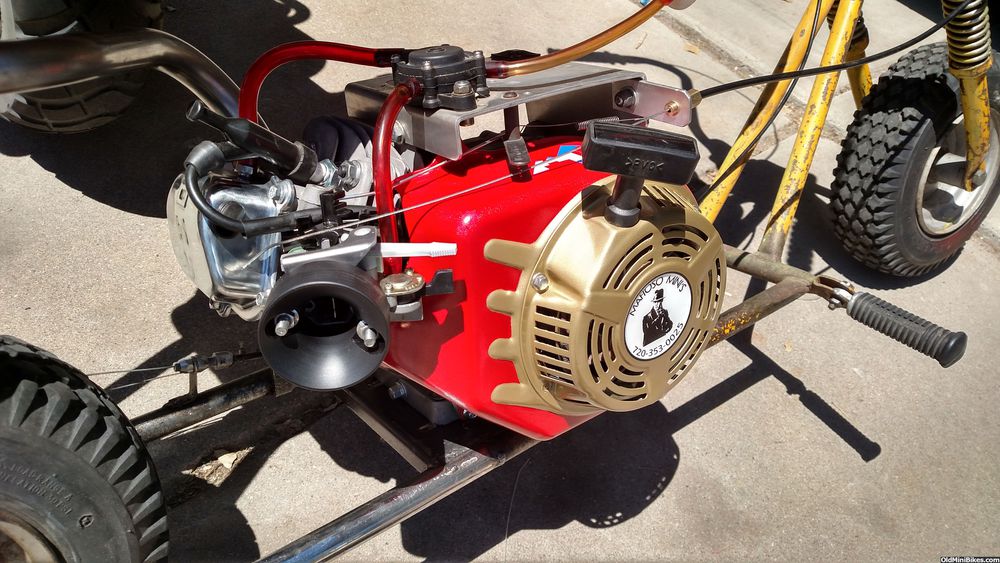

And installed in the bike along with new(ish) tires, (off my Sensation bobber project) new tubes and bearings

I also installed a new RLV gold chain on the Max Torque clutch

What a difference! This bike pulls hard now and the exhaust note is cracking!