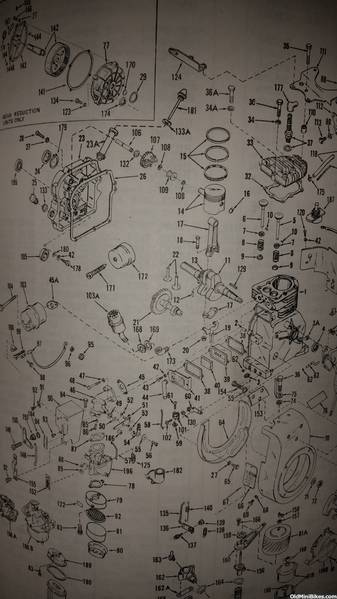

I am going to use this old Tecumseh on this bike (dubbed the Flying Grapefruit by my daughter)but its got the other kind of gov linkage in place for when it had the updraft Tillotson carb. Just wondering if anyone has converted this set up to the regular one. Can I just take it all out and put the long gov lever on? How should I do that?

I would like to use this black throttle bracket with a long neck gov lever.

I would like to use this black throttle bracket with a long neck gov lever.