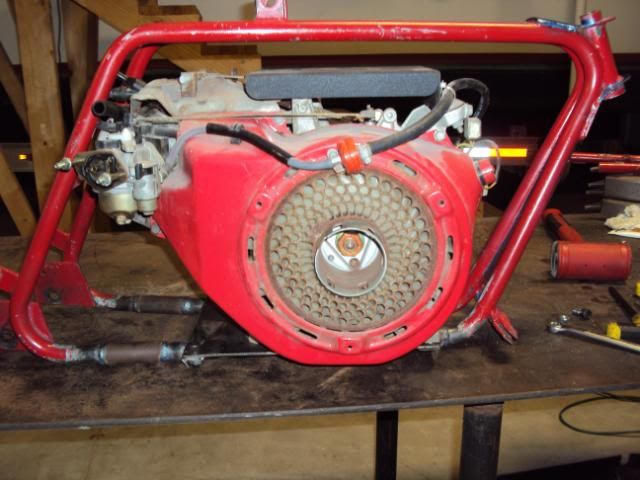

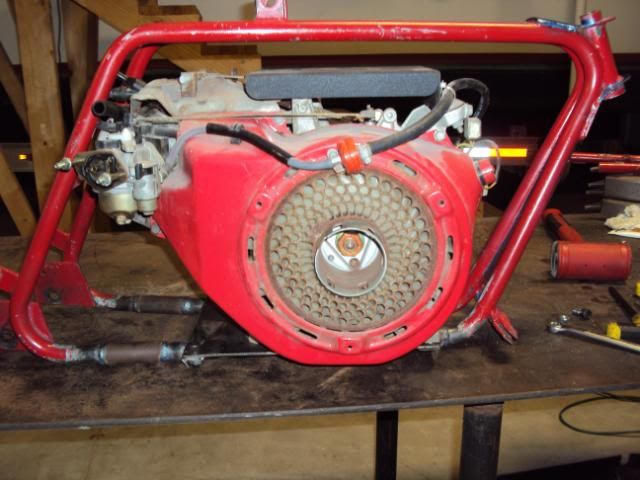

I have this cx390 honda laying around collecting dust so I thought I would see if it fit's and.....it does.It has a tapered output shaft but I have access to a crankshaft grinder, a lathe,and a Bridgeport mill.If I could fit a tav this thing would haul some serious ass..

Any imput???????????????????????

Any imput???????????????????????