I have an electrician coming to do some work. I am going to have him run a line so I can run a better Welder.(which I don't have yet or even know what model)I have seen different outlets for 220v. Can someone suggest which style I should get for the outlet itself? Also, what amperage breaker should I use?

A 6-50 plug is standard on welders, so I recommend a 6-50 receptacle. That is different from the dryer or stove plug, but since you will have a dedicated outlet I would go with standard. You can always make an adapter cord to go from 6-50 to dryer plug later if needed.

I have a 50 amp breaker to all my welder circuits (5 in my shop, hate plugging and unplugging) and I have never popped a breaker. My Syncrowave 250 calls for a 100 amp breaker, I think, but I never run at full power as a hobbiest. I easily weld aluminum with it.

If you buy an inverter welder, I believe most of them call for a 30 amp breaker. Doesn't hurt to go higher.

Your electrician should know the code allows him to use a smaller wire (de-rated wire) on a dedicated welding circuit. So if you have a long drop it will save you some money on the wire, but if it is relatively close to the breaker box I would use the standard wire. For 30 amp you need 10 gauge wire, for 50 amp use 6 gauge.

You only need 3 wires - 2 hots and a ground. Welders do not need a neutral.

I have a 50 amp breaker to all my welder circuits (5 in my shop, hate plugging and unplugging) and I have never popped a breaker. My Syncrowave 250 calls for a 100 amp breaker, I think, but I never run at full power as a hobbiest. I easily weld aluminum with it.

If you buy an inverter welder, I believe most of them call for a 30 amp breaker. Doesn't hurt to go higher.

Your electrician should know the code allows him to use a smaller wire (de-rated wire) on a dedicated welding circuit. So if you have a long drop it will save you some money on the wire, but if it is relatively close to the breaker box I would use the standard wire. For 30 amp you need 10 gauge wire, for 50 amp use 6 gauge.

You only need 3 wires - 2 hots and a ground. Welders do not need a neutral.

Last edited:

I use a dryer style plug with the added benifit of finding new cords out at the curb on garbage day

I have an illegal suicide cord made to plug my generator into the welder plug , It then back feeds the house from the garage

(With the main breaker off to protect the linesmen who may be out repairing the lines)

I have an illegal suicide cord made to plug my generator into the welder plug , It then back feeds the house from the garage

(With the main breaker off to protect the linesmen who may be out repairing the lines)

A 6-50 plug is standard on welders, so I recommend a 6-50 receptacle. That is different from the dryer or stove plug, but since you will have a dedicated outlet I would go with standard. You can always make an adapter cord to go from 6-50 to dryer plug later if needed.

I have a 50 amp breaker to all my welder circuits (5 in my shop, hate plugging and unplugging) and I have never popped a breaker. My Syncrowave 250 calls for a 100 amp breaker, I think, but I never run at full power as a hobbiest. I easily weld aluminum with it.

If you buy an inverter welder, I believe most of them call for a 30 amp breaker. Doesn't hurt to go higher.

Your electrician should know the code allows him to use a smaller wire (de-rated wire) on a dedicated welding circuit. So if you have a long drop it will save you some money on the wire, but if it is relatively close to the breaker box I would use the standard wire. For 30 amp you need 10 gauge wire, for 50 amp use 6 gauge.

You only need 3 wires - 2 hots and a ground. Welders do not need a neutral.

I have a 50 amp breaker to all my welder circuits (5 in my shop, hate plugging and unplugging) and I have never popped a breaker. My Syncrowave 250 calls for a 100 amp breaker, I think, but I never run at full power as a hobbiest. I easily weld aluminum with it.

If you buy an inverter welder, I believe most of them call for a 30 amp breaker. Doesn't hurt to go higher.

Your electrician should know the code allows him to use a smaller wire (de-rated wire) on a dedicated welding circuit. So if you have a long drop it will save you some money on the wire, but if it is relatively close to the breaker box I would use the standard wire. For 30 amp you need 10 gauge wire, for 50 amp use 6 gauge.

You only need 3 wires - 2 hots and a ground. Welders do not need a neutral.

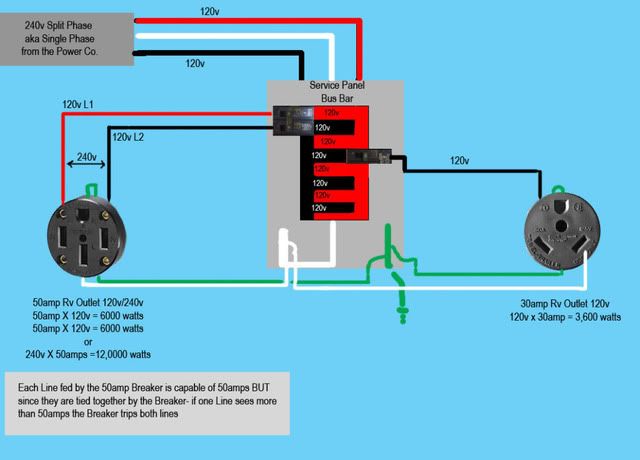

Simple, heavy duty shop wiring

What I have so far:

The 50 Amp 4-prong has 6 gauge wires, 50 Amp breaker, runs a Miller Thunderbolt AC/DC stick welder, Lincoln IdealArc 250, big air compressor, or the motorcoach extension cord.

The smaller round 3 prong is 220 Volts through 10 gauge wires, 25 Amp breaker, runs a HF scratch start stick/TIG welder, Northern Tool 4,000 Watt heater, small air conditioner, table saw, or the 3,000 Watt powder coating oven.

The quad of 20 Amp 120 Volt receptacles has 12 gauge wires to a 20 Amp breaker, runs the heavier power tools like the wood chop saw, metal chop saw, lathe/mill, and the grinders.

All those outlets were added just below the breaker panel, because all other wiring goes up and out the top of the box. Plenty of Amps preserve expensive power tool motors.

A few smaller outlets around the shop power portable lighting, battery chargers, soldering tools, sanders, small saws and low-Amp devices.

What I have so far:

The 50 Amp 4-prong has 6 gauge wires, 50 Amp breaker, runs a Miller Thunderbolt AC/DC stick welder, Lincoln IdealArc 250, big air compressor, or the motorcoach extension cord.

The smaller round 3 prong is 220 Volts through 10 gauge wires, 25 Amp breaker, runs a HF scratch start stick/TIG welder, Northern Tool 4,000 Watt heater, small air conditioner, table saw, or the 3,000 Watt powder coating oven.

The quad of 20 Amp 120 Volt receptacles has 12 gauge wires to a 20 Amp breaker, runs the heavier power tools like the wood chop saw, metal chop saw, lathe/mill, and the grinders.

All those outlets were added just below the breaker panel, because all other wiring goes up and out the top of the box. Plenty of Amps preserve expensive power tool motors.

A few smaller outlets around the shop power portable lighting, battery chargers, soldering tools, sanders, small saws and low-Amp devices.

It would be about a 25 foot run from the box to the outlet. I may do the one outlet and then use an adapter for different type of plug. I am going to also have him hook up the generator outlet right next to to box since it is in the garage. Then I will just run the generator outside with an extension cord. I am also going to use an interlock switch to have zero chance of backfeeding to the pole.

The interlock switch is really just a plate that slides down or over depending on your box configuration. It only allows the generator breaker to be thrown when the main is in the off position. They still charge a lot for just a sliding plate but still cheaper than the switch I think. But one day I hope to have it all automated with a propane/natural gas generator. Then you don't have to worry about the fuel going bad.

Interlok switch or transfer switch is fine, but to backfeed a circuit and depend on someone to remember to throw the main is dangerous.

Maybe you know to do that, but does your son or neighbor? They just see you plug it in and start the generator. The power company guys already have enough danger during a storm cleanup, they should not have to worry about getting shocked like that.

If you have natural gas available, that is the best option. I had to add a large propane tank and underground pipe. Cost about $700 just to install plus the gas. And propane can run out whereas natural gas should flow in almost every scenario.

Maybe you know to do that, but does your son or neighbor? They just see you plug it in and start the generator. The power company guys already have enough danger during a storm cleanup, they should not have to worry about getting shocked like that.

If you have natural gas available, that is the best option. I had to add a large propane tank and underground pipe. Cost about $700 just to install plus the gas. And propane can run out whereas natural gas should flow in almost every scenario.

Interlok switch or transfer switch is fine, but to backfeed a circuit and depend on someone to remember to throw the main is dangerous.

Maybe you know to do that, but does your son or neighbor? They just see you plug it in and start the generator. The power company guys already have enough danger during a storm cleanup, they should not have to worry about getting shocked like that.

If you have natural gas available, that is the best option. I had to add a large propane tank and underground pipe. Cost about $700 just to install plus the gas. And propane can run out whereas natural gas should flow in almost every scenario.

Maybe you know to do that, but does your son or neighbor? They just see you plug it in and start the generator. The power company guys already have enough danger during a storm cleanup, they should not have to worry about getting shocked like that.

If you have natural gas available, that is the best option. I had to add a large propane tank and underground pipe. Cost about $700 just to install plus the gas. And propane can run out whereas natural gas should flow in almost every scenario.

I work with Linemen everyday as a System Operator. A main breaker is NOT a safe way to isolate from the grid. You need a visible open as in a throw switch. Breakers can fry and become conductive. When your little 240 Generator backfeeds up your service wire to the transformer, it steps the voltage up to 7200 volts or higher depending on the distribution voltage. If you don't kill a lineman you will at least fry your generator as it tries to power up all your neighbors. Do it right and use a contractor and do it to code.

Fred

Fred