Hi everyone,

This will be the build log for my 2x2 project.

I love tinkering and have completed a few big projects in the past including a 4x4 buggy, but this will be my first 2 wheeled project. In fact I have only ridden a mini bike once and crashed almost immediately...... but I'll figure it out.

On to the tech.

Here is what I have so far:

1984 Honda atc125m for the engine/trans

25x13-9 Duro hf243 4 ply tires on 9x9 wheels

1000 lb capacity trailer hubs/spindles

6" Airheart discs and mechanical calipers

Tractor PTO overrunning coupler

1" keyed U-joint

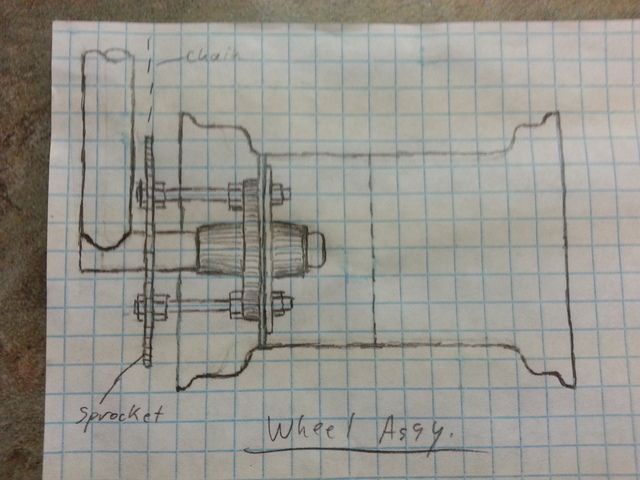

Buttload of sprockets, bearings, chain, and keyed shafting

The Plan:

I will fabricate the frame from scratch, and there will be no suspension, only tire flex and a sprung seat. The forks and rear "arm" will be single sided. Inboard brakes. And of course a winch and snorkle. This thing is being built extra heavy duty for extreme abuse.... 1" shafting and #50 chain!

Pics:

Good running donor. Electric start 4 speed with hi/low range.

Wrinkly tires.....had to use the lighter fluid bead setting technique.

25x13-9 compared to 22x11-8 from the three wheeler.

Tractor pto overrunning coupler to allow the front wheel to go faster than the rear in a turn. I plan on cutting it down and welding on a sprocket.

This will be the build log for my 2x2 project.

I love tinkering and have completed a few big projects in the past including a 4x4 buggy, but this will be my first 2 wheeled project. In fact I have only ridden a mini bike once and crashed almost immediately...... but I'll figure it out.

On to the tech.

Here is what I have so far:

1984 Honda atc125m for the engine/trans

25x13-9 Duro hf243 4 ply tires on 9x9 wheels

1000 lb capacity trailer hubs/spindles

6" Airheart discs and mechanical calipers

Tractor PTO overrunning coupler

1" keyed U-joint

Buttload of sprockets, bearings, chain, and keyed shafting

The Plan:

I will fabricate the frame from scratch, and there will be no suspension, only tire flex and a sprung seat. The forks and rear "arm" will be single sided. Inboard brakes. And of course a winch and snorkle. This thing is being built extra heavy duty for extreme abuse.... 1" shafting and #50 chain!

Pics:

Good running donor. Electric start 4 speed with hi/low range.

Wrinkly tires.....had to use the lighter fluid bead setting technique.

25x13-9 compared to 22x11-8 from the three wheeler.

Tractor pto overrunning coupler to allow the front wheel to go faster than the rear in a turn. I plan on cutting it down and welding on a sprocket.