Earlier, I had posted I got the brake figured out. It worked great, until I mounted the engine and just didn't have the clearance for the darn cable. (Part of my recent engineering void frame of mind)

Old:

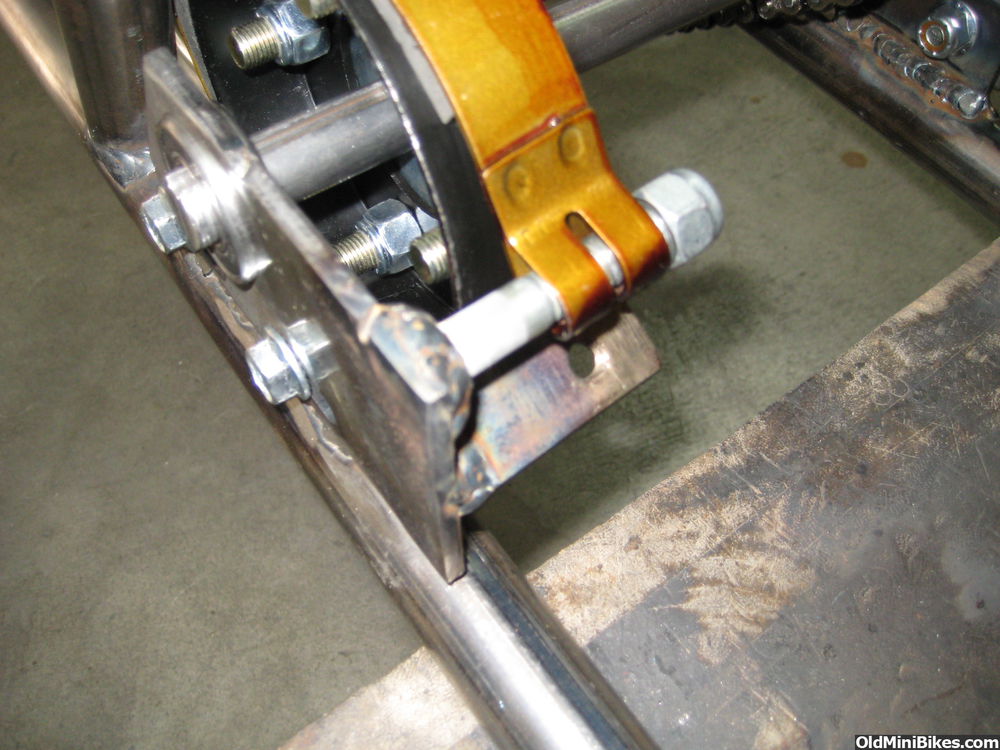

So I cut everything off the jackshaft plate for the third time, and attempt number IV was successful. The brake even works better, less drag, more of the groovy wrap-around deal we all know and love.

New:

As loose as it is on the photo, I still have some "brake" at the end of the lever range, and no rubbing. I ought to quit now and imbibe in adult beverages, however my Doctor said I had to slow down. Bunch of BS there. So now wife doesn't buy beer, and I am limited to three vodka and cranberry cocktails per day. There is just no joy in that. Don't even get to smash cans. It's just not a garage drink, ya know? And my garage refrigerator just sits there, looking forlorn.

Old:

So I cut everything off the jackshaft plate for the third time, and attempt number IV was successful. The brake even works better, less drag, more of the groovy wrap-around deal we all know and love.

New:

As loose as it is on the photo, I still have some "brake" at the end of the lever range, and no rubbing. I ought to quit now and imbibe in adult beverages, however my Doctor said I had to slow down. Bunch of BS there. So now wife doesn't buy beer, and I am limited to three vodka and cranberry cocktails per day. There is just no joy in that. Don't even get to smash cans. It's just not a garage drink, ya know? And my garage refrigerator just sits there, looking forlorn.