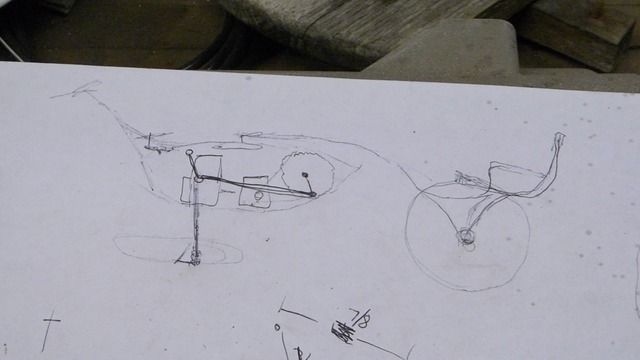

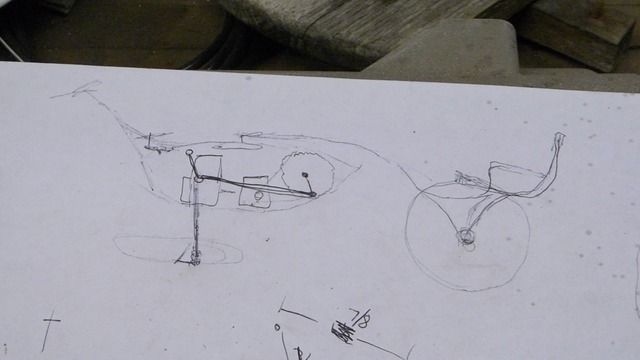

Now for something completely different. Im building a mechanical walking machine it will be like an emu/ostrich style bird with all the mecanical guts in its body. Pulling a wagon with the rider. The wagon will serve to stabilize the 2 leged bird. Iv always wanted to build a 4 legged animal to ride but making that work and be stable and turn just gets too complicated. Recently a saw a few utube videos that gave me a solid plan. Im going to use a hf 79cc because of its low profile rather than the briggs. and ill probrobly put the gas tank up in the neck. iv got a peerless 5 speed for speed control. Ill probrobly make the birds tail the shifter and have only a throttle control on the wagon. Im going to try to use a centrifical clutch. The only downside to this is itll have to run a higher rpm rather than quietly puttering along. I will leave room for a belt tensioner setup if it doesnt work out. but id prefer the simplicity of the chain setup. I just took measurements of the computer screen for the legs and today i made a cardboard template to finalize the measurements for the best range of motion. The steering will be by rope but itll be geared down to dampen the side to side pulling of the legs. im also going to make the head turn side to side with the steering. The body will be bolted together like a clamshell so i can get to the inards. Its going to be quite the progect but its uniqueness should keep me intrested. Im going to pick up an engine tomorrow and get started on the body.

Range of motion test video>

Here is the utube video of the leg design

https://www.youtube.com/watch?v=oNh8vvIkOJY&index=26&list=WL

Range of motion test video>

Here is the utube video of the leg design

https://www.youtube.com/watch?v=oNh8vvIkOJY&index=26&list=WL

Last edited: