Despite a doctors appt, a wedding, and a birthday party, I did make a little progress this weekend.

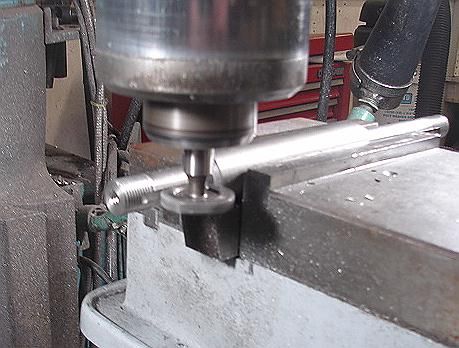

I finished the swing arm, and made a motor mount plate. The only thing holding me up is the jack shaft tube. Soon as I get the bearings I can turn the jack shaft. I still have to make the swing arm pivot shaft, which will also double as the brake lever pivot.

I finished the swing arm, and made a motor mount plate. The only thing holding me up is the jack shaft tube. Soon as I get the bearings I can turn the jack shaft. I still have to make the swing arm pivot shaft, which will also double as the brake lever pivot.

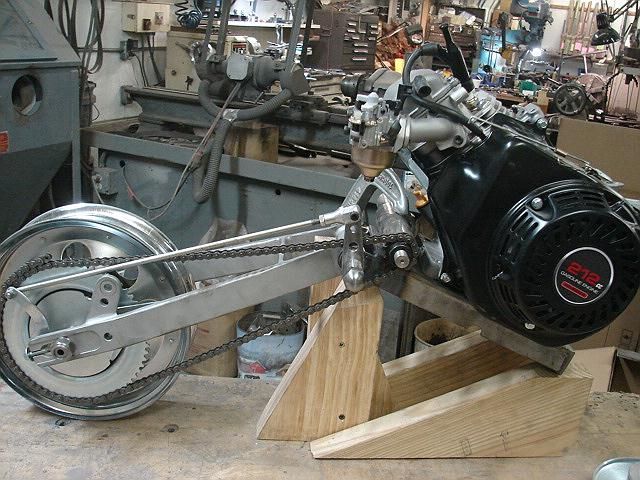

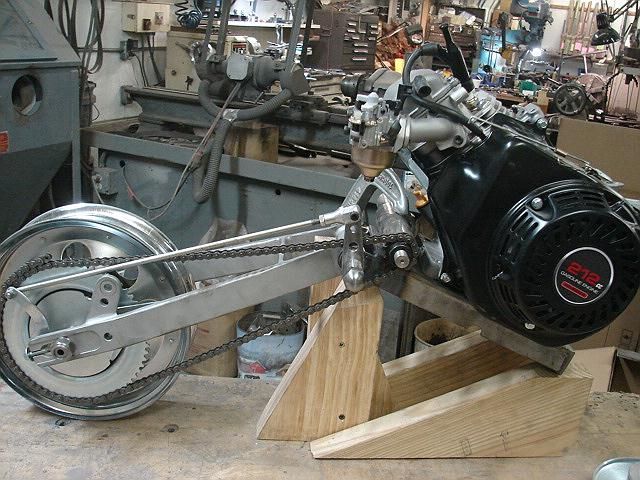

While waiting on some goodies to come in, I figured I get some details out of the way. I didn't like the way the carburetor was facing, so I make a angled manifold to level it out and face it to the rear.

I fabbed up the rear brake linkage, and extended the swing arm pivot to double as a mount for the brake pedal.

I think I have all the critical things under control. I just received my jack shaft bearings today and I'm currently on that. Once I get the jack shaft tube welded in place, I can start welding the rest of the frame....WOO HOO!!! I might have a roller by this weekend!

I fabbed up the rear brake linkage, and extended the swing arm pivot to double as a mount for the brake pedal.

I think I have all the critical things under control. I just received my jack shaft bearings today and I'm currently on that. Once I get the jack shaft tube welded in place, I can start welding the rest of the frame....WOO HOO!!! I might have a roller by this weekend!

I got the chance to start on the frame, and must say most of the work is getting things all jigged up. Between angle plates, 123 blocks, parallels, and levels and fighting clamps, I got the neck straight with the rest of the world.

The rest was a lot simpler, once I established a center line and how to keep things on it.

I got everything tacked up and gave it a once over for straightness and square and she passed with flying colors. I thought before I would start burning wire, I'd throw the engine on just to see what it looked like. Good thing I did....I'll be a sonafa#$%% if the spark plug didn't hit the top tube dead center! Damn...that didn't show up on the drawings. With that spark plug boot thingamabob adding 2", I couldn't even got this thing in with out hitting seat. So now I have to cut a section out of the tube and build a bridge. So I went with plan "B"

I have enough room for the plug now, but the boot makes it up against the bottom of the seat.

So how much of a pita is it to change out the spark plug wire for something that has a simple right angle connection?

The rest was a lot simpler, once I established a center line and how to keep things on it.

I got everything tacked up and gave it a once over for straightness and square and she passed with flying colors. I thought before I would start burning wire, I'd throw the engine on just to see what it looked like. Good thing I did....I'll be a sonafa#$%% if the spark plug didn't hit the top tube dead center! Damn...that didn't show up on the drawings. With that spark plug boot thingamabob adding 2", I couldn't even got this thing in with out hitting seat. So now I have to cut a section out of the tube and build a bridge. So I went with plan "B"

I have enough room for the plug now, but the boot makes it up against the bottom of the seat.

So how much of a pita is it to change out the spark plug wire for something that has a simple right angle connection?