this motor is going on another project, in another thread... but thought Id post a thread on it specifically, as alot of people prob wont realize what all is going into that "cruiser project", or may not like taco 22 style bikes.. hoping to have the motor dyno'd if i can find someone to do this locally... when done... pretty far along and I will post more detailed info on the build at a later time.. but here we go...

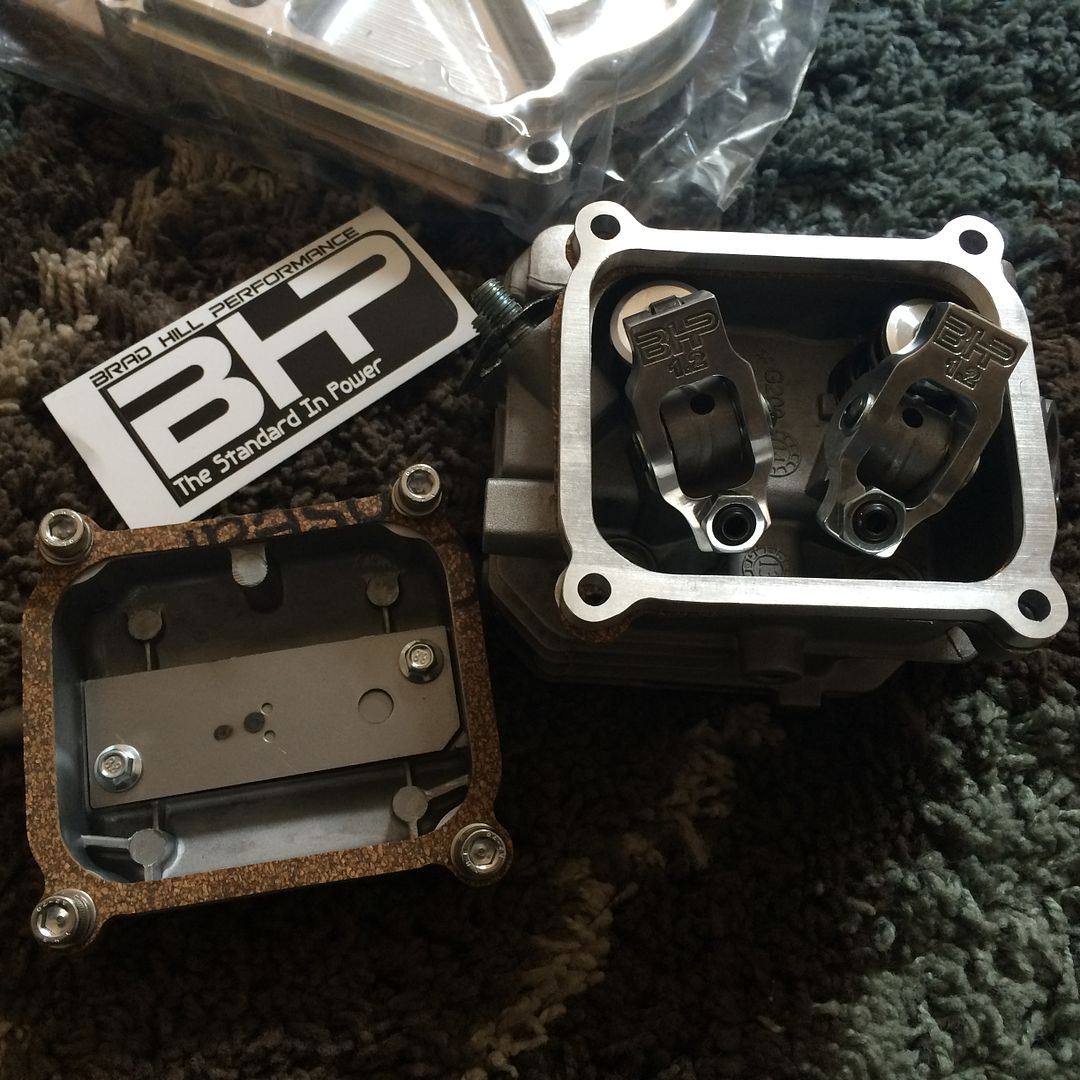

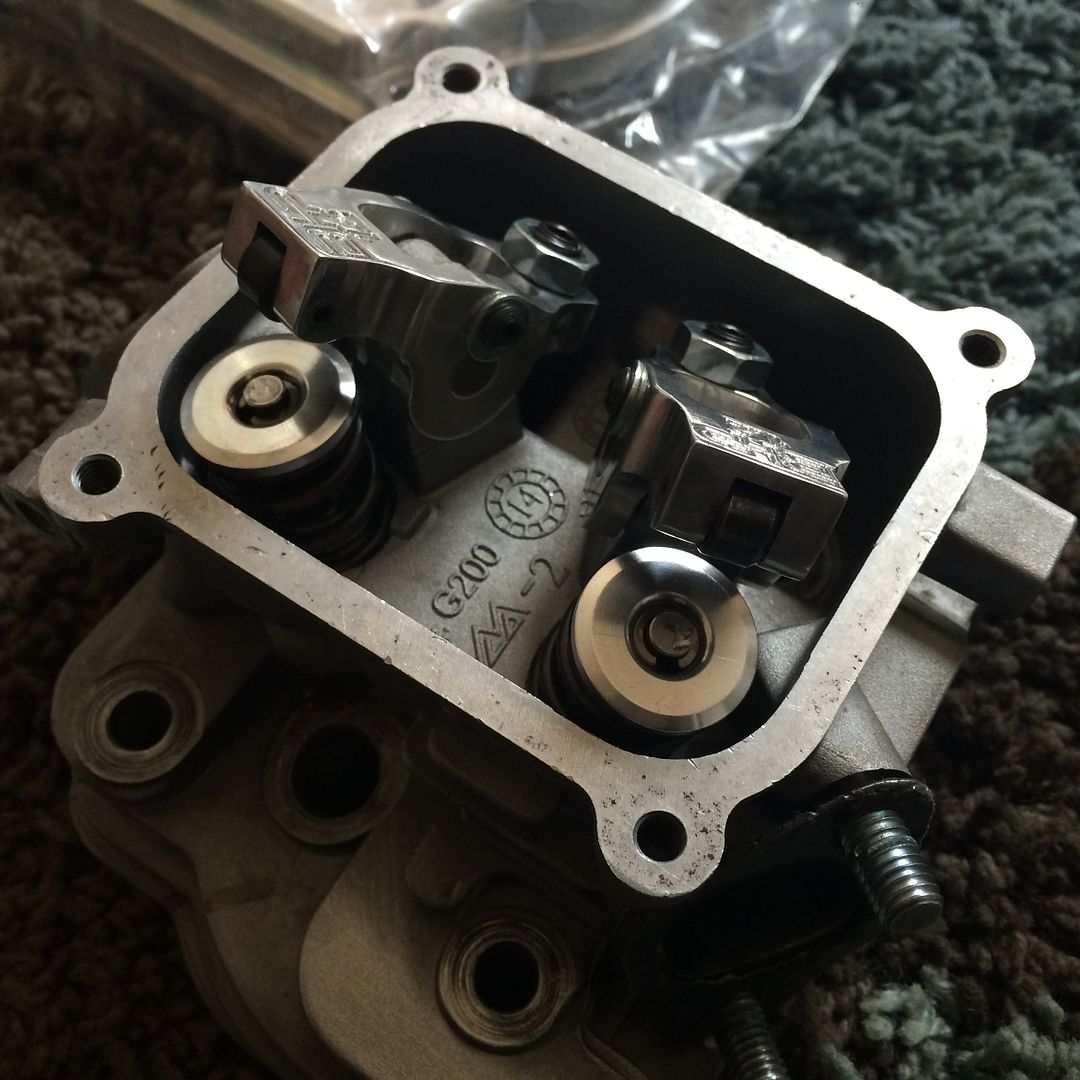

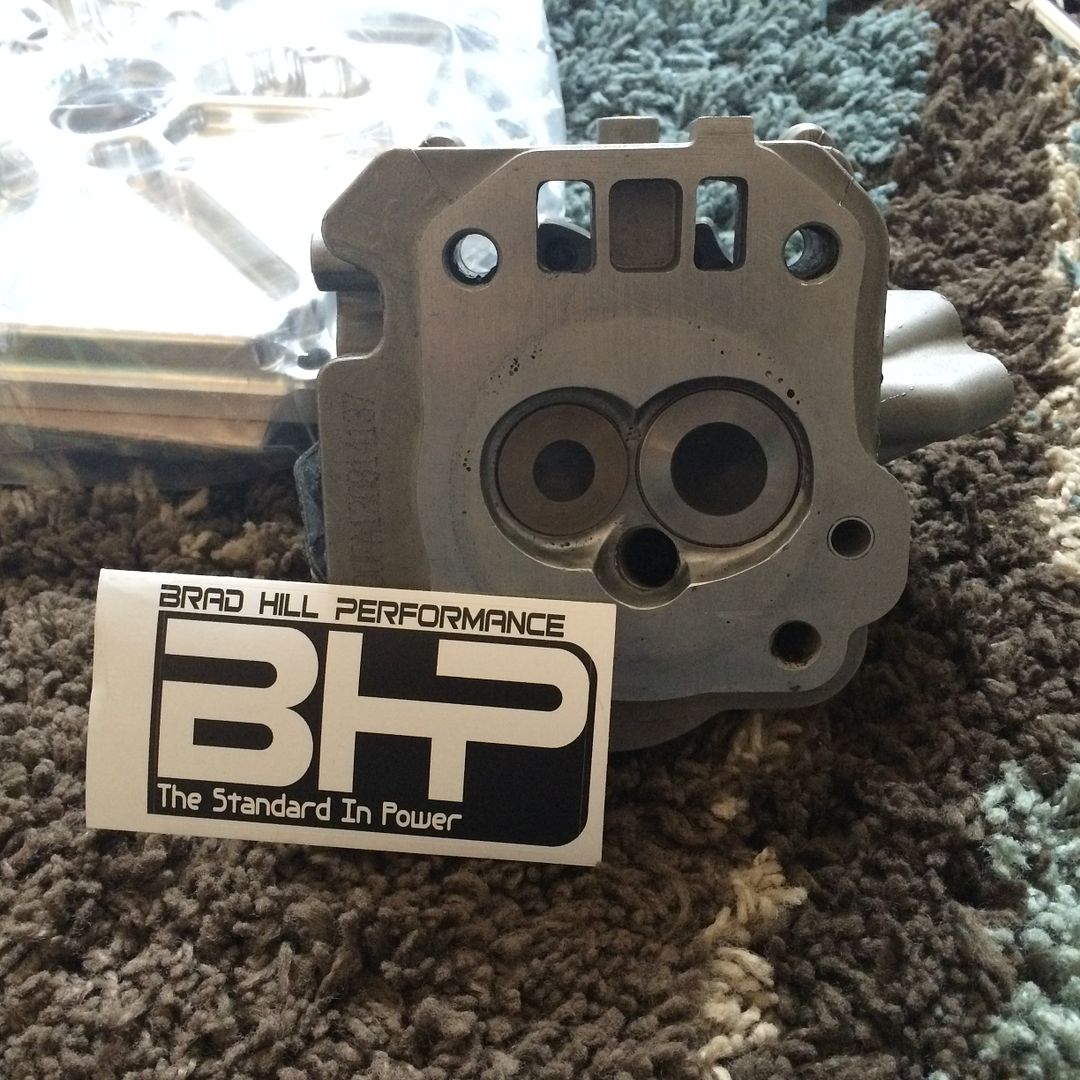

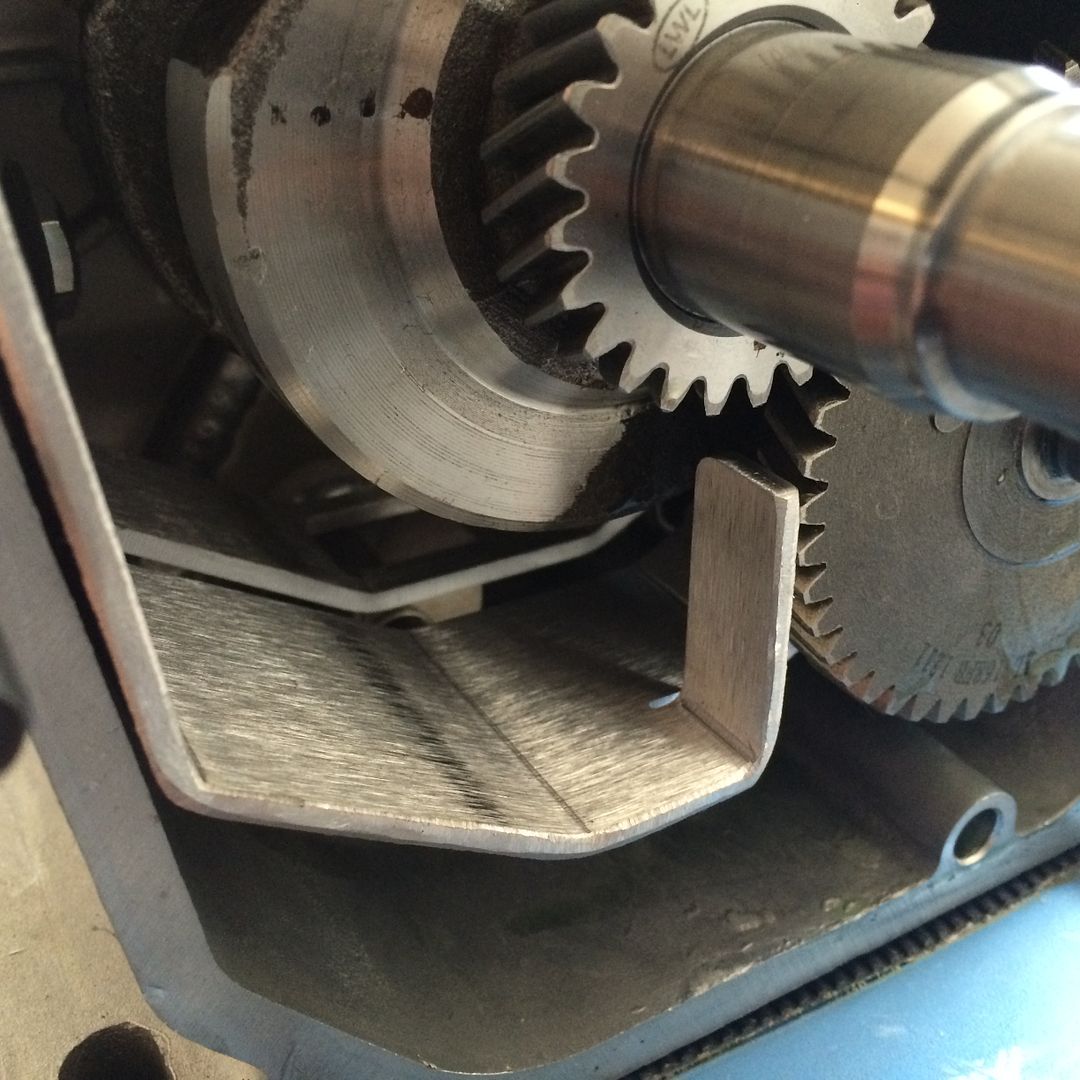

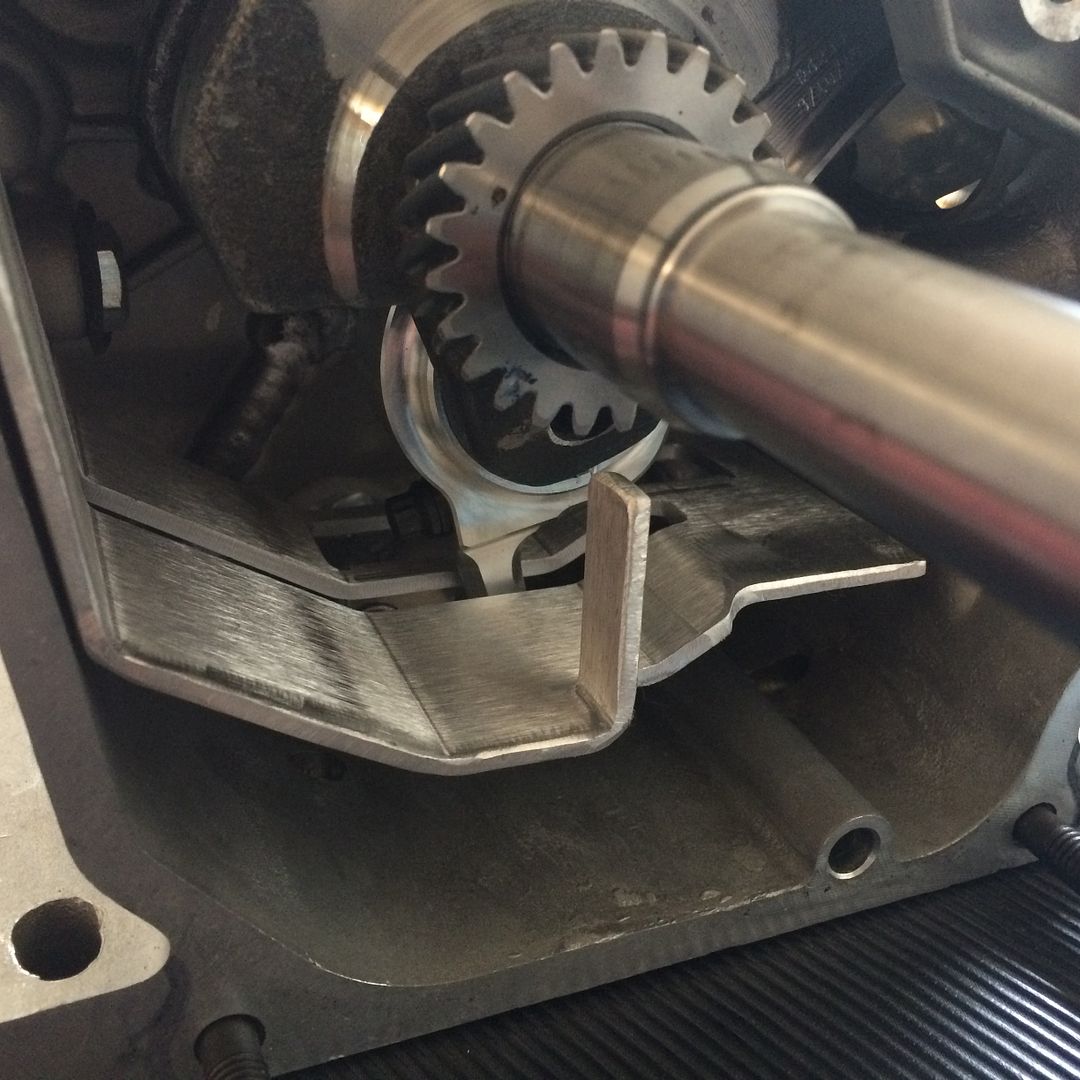

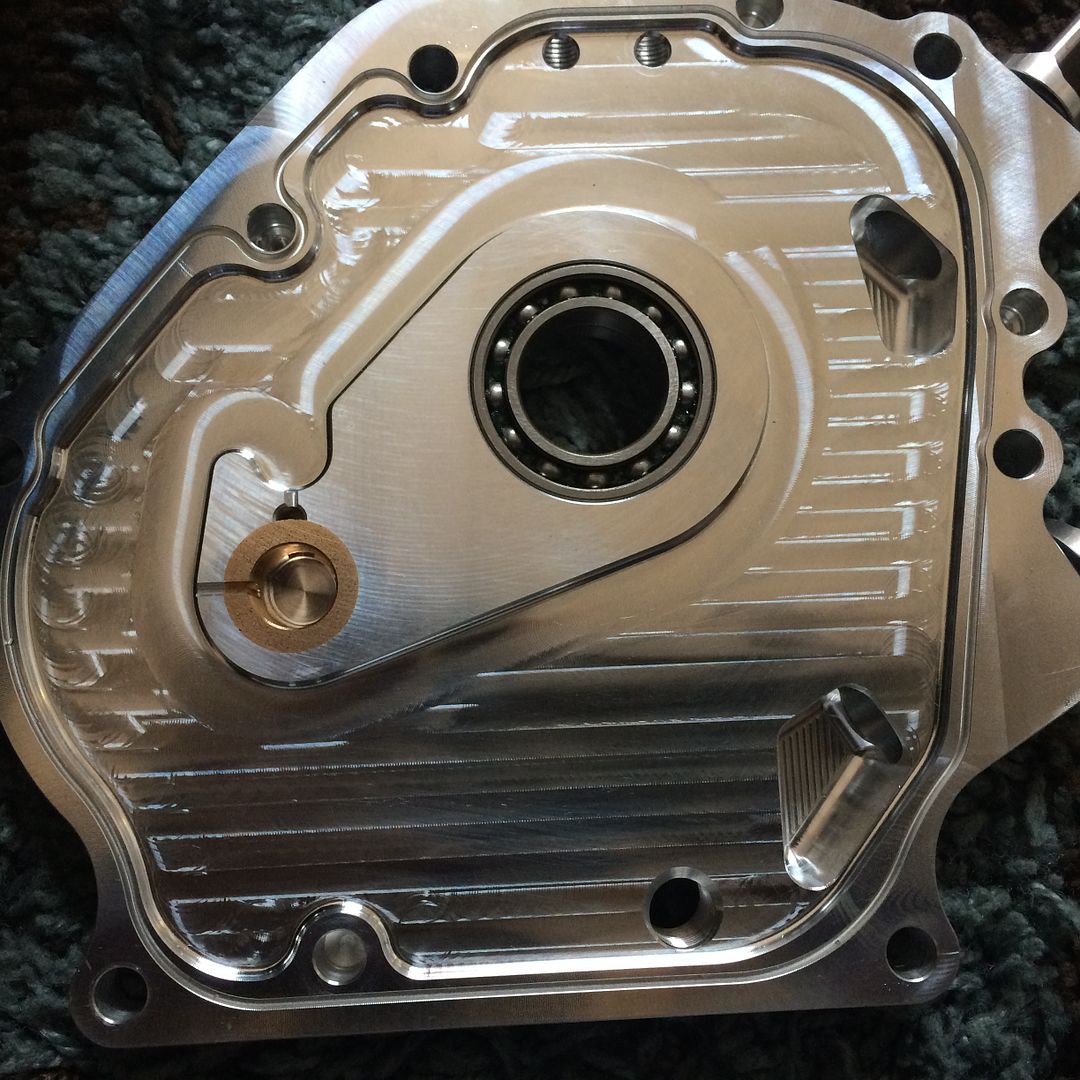

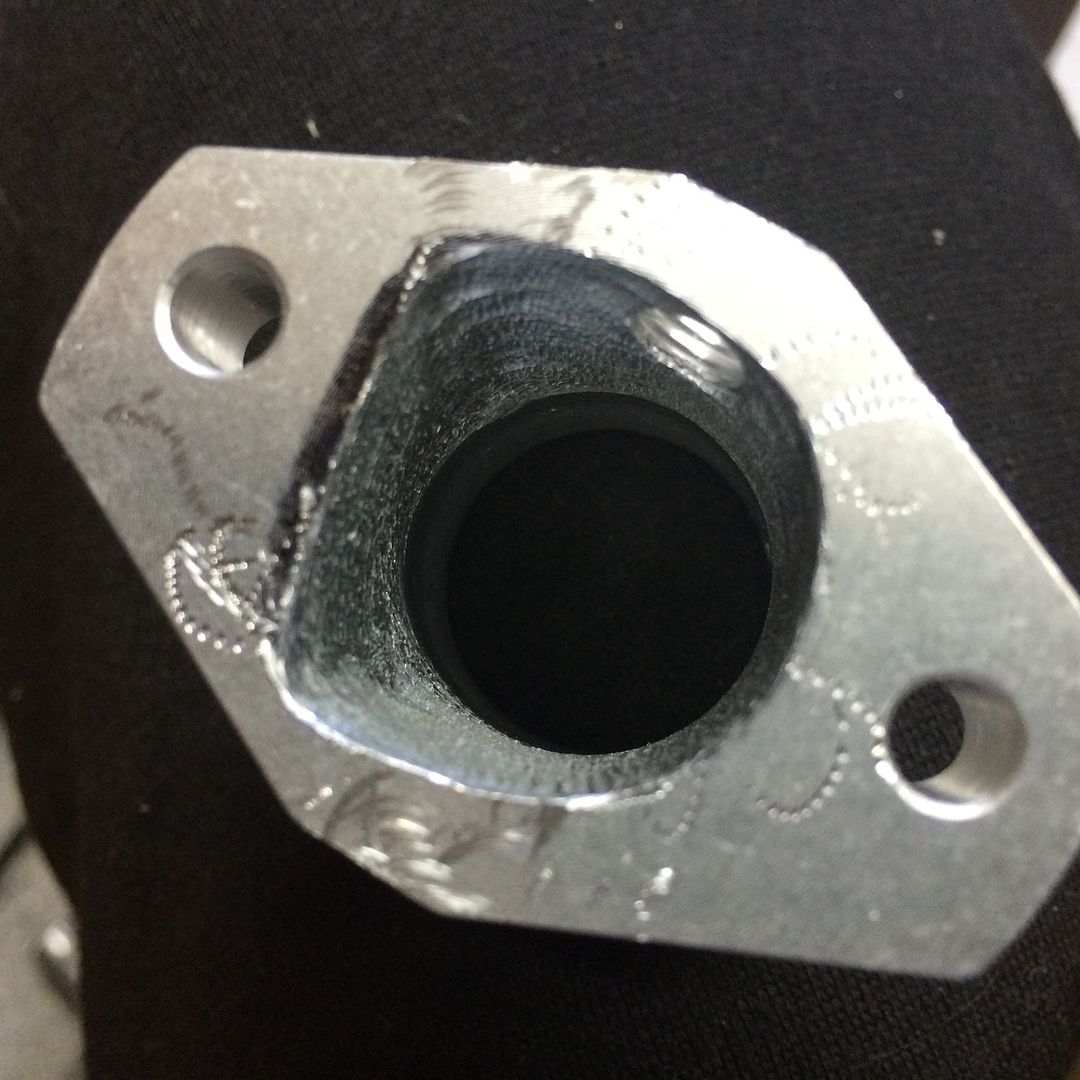

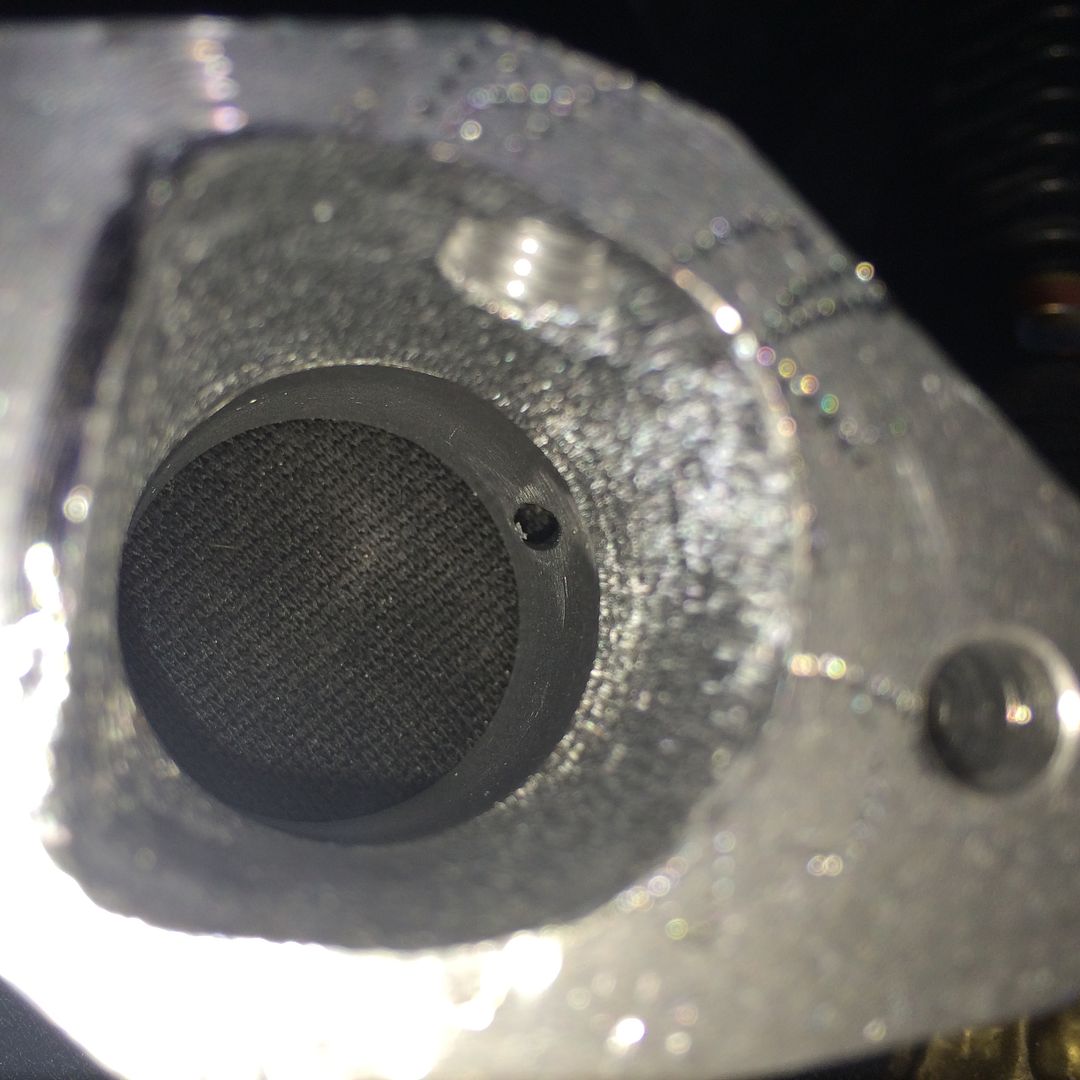

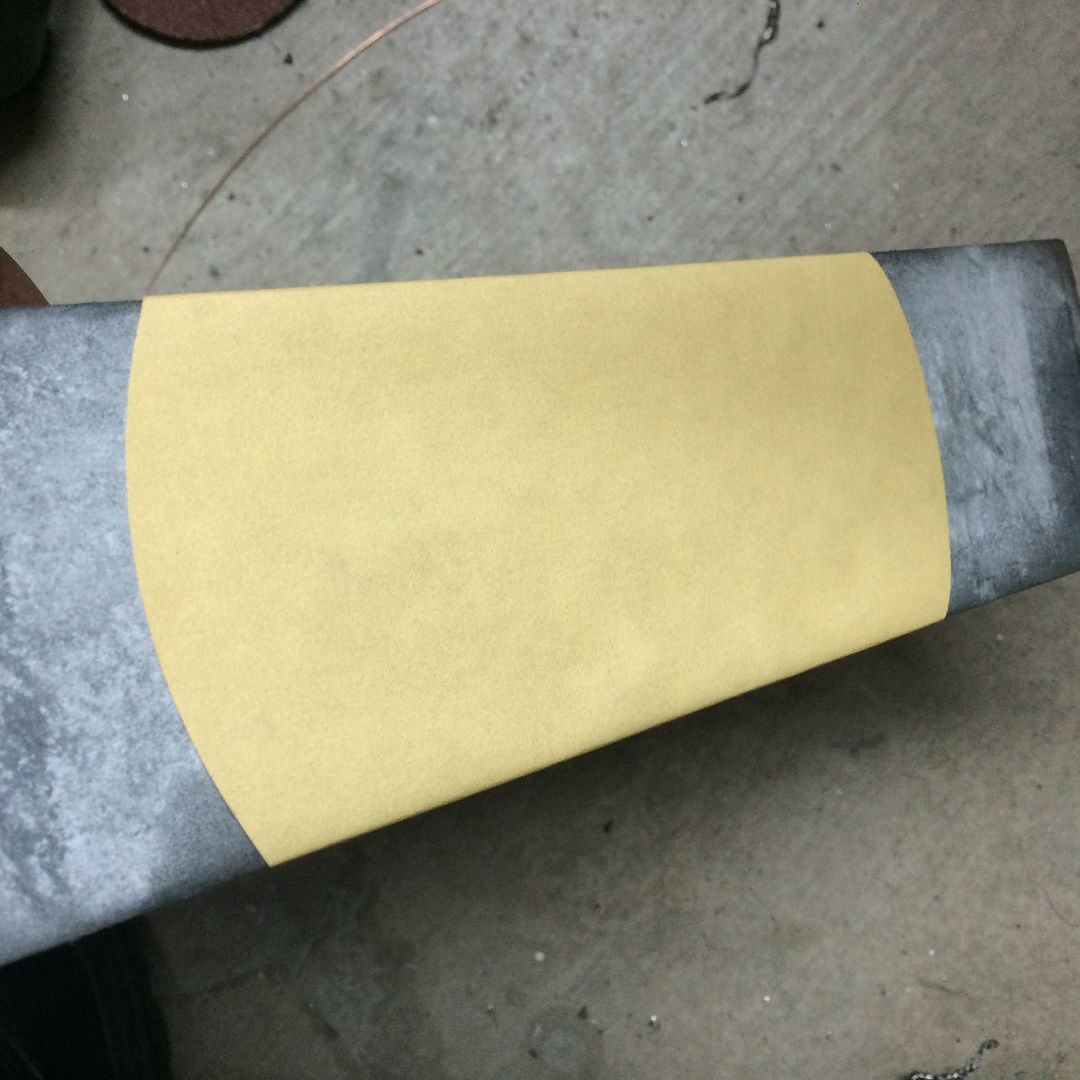

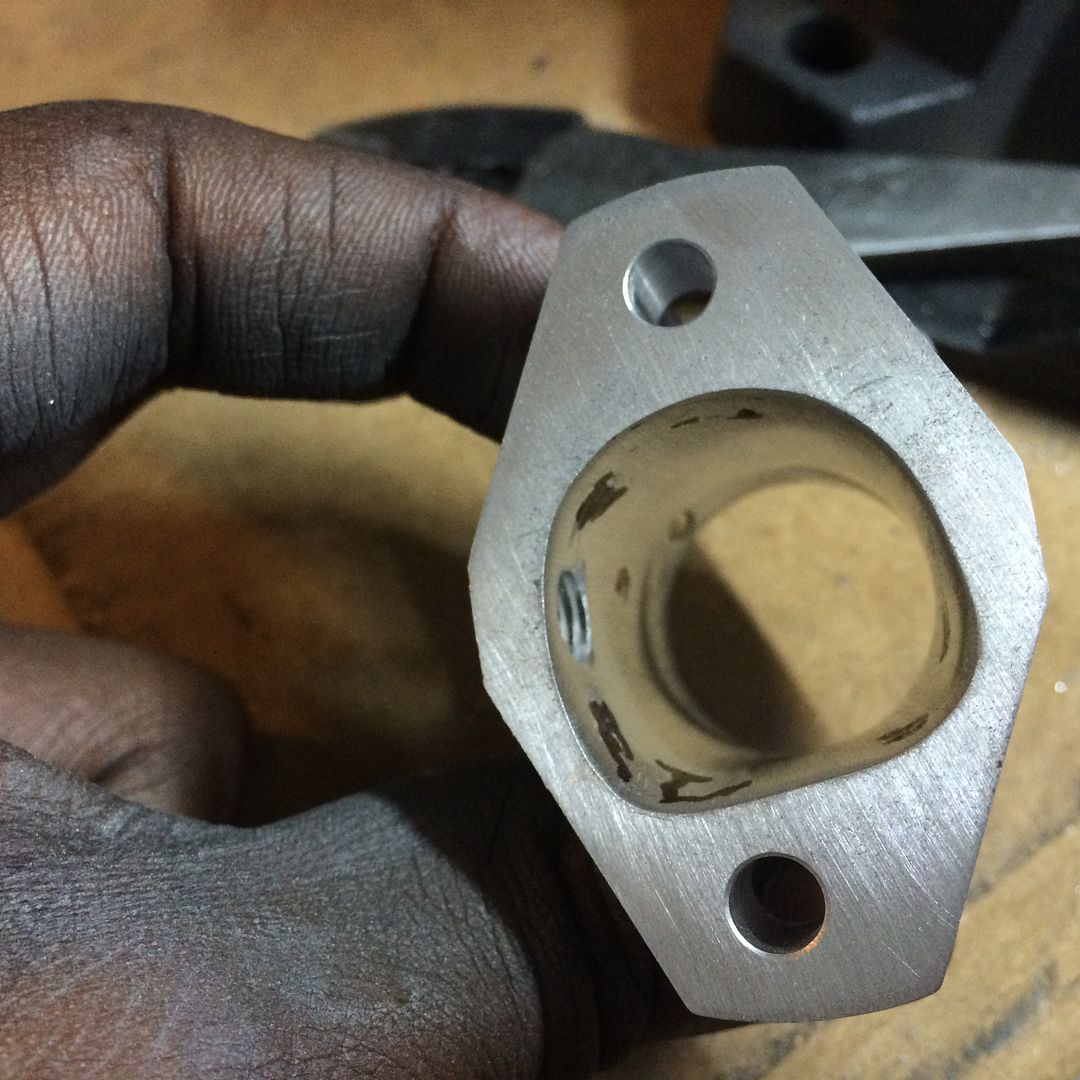

short block, fully braced... gas ported piston... Brad Hill Performance built hemi head (welded, race ported, comp springs, big valve, custom billet roller rockers 1.2s) custom cam, misc billet and chromoly parts, pieces...

short block, fully braced... gas ported piston... Brad Hill Performance built hemi head (welded, race ported, comp springs, big valve, custom billet roller rockers 1.2s) custom cam, misc billet and chromoly parts, pieces...