FS Burnishing for minibike parts (pics)

- Thread starter cambo61

- Start date

- Tags burnishing minibike pics

It's been awhile since I've posted some work. I'm happy to get calls and texts from hobbiests showing me their projects! I got 2 today!

OND posted his sorry looking 4" Lil Indians above. I got them Wed night and shipped them out this morning. He will be in shock when he gets them back.

I've got more pictures of jobs coming. I'm considering buying a zinc plating operation to help everyone out with their restorations. Commercial platers don't want our work and they usually charge an $80 minimum. I'll make a decision in January and I think I can do it for far less than what they charge. I've got a day job. For me this is a hobby and therefore I can charge hobby prices. Let's keep this affordable so we can all have nice stuff.

OND posted his sorry looking 4" Lil Indians above. I got them Wed night and shipped them out this morning. He will be in shock when he gets them back.

I've got more pictures of jobs coming. I'm considering buying a zinc plating operation to help everyone out with their restorations. Commercial platers don't want our work and they usually charge an $80 minimum. I'll make a decision in January and I think I can do it for far less than what they charge. I've got a day job. For me this is a hobby and therefore I can charge hobby prices. Let's keep this affordable so we can all have nice stuff.

Thanks for the support Manchester.

Here is the 2nd set of Bonanza wheels for Dragracertpp. They took some blasting and about 2 hours in the burnisher. I had them in the mail 24hrs later.

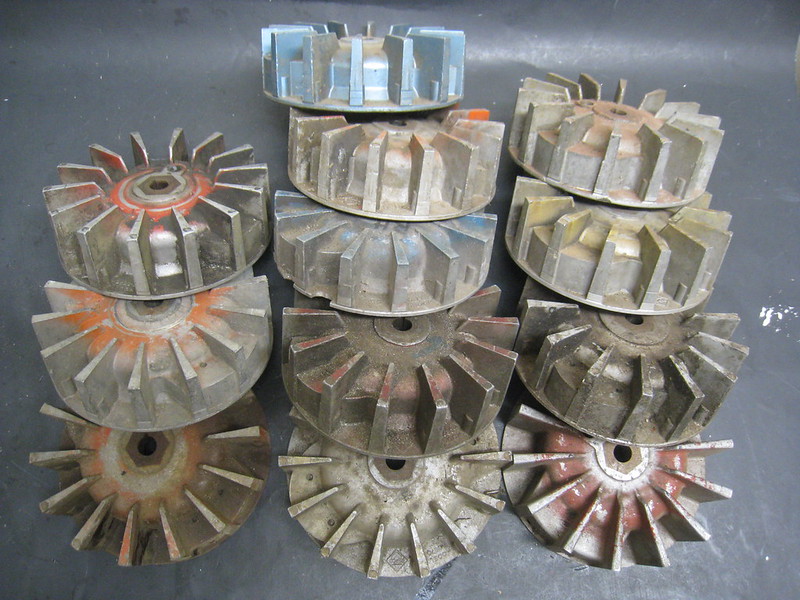

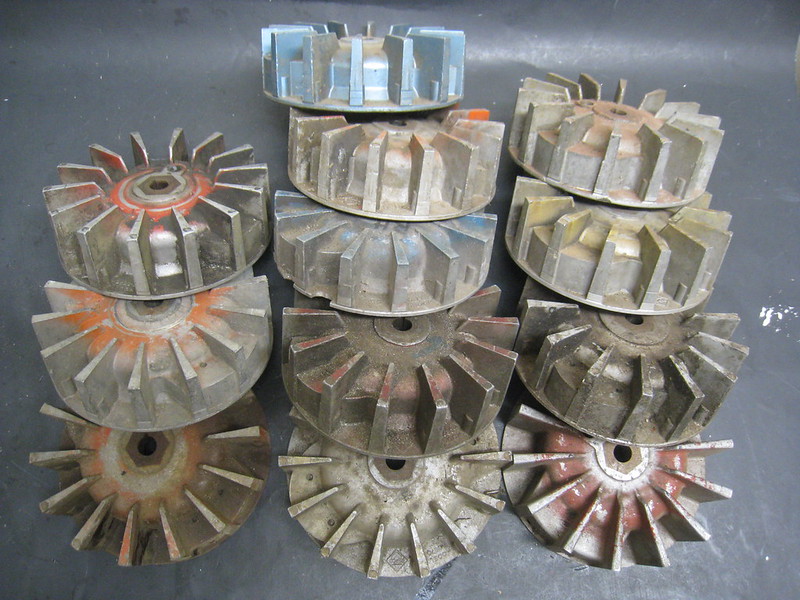

My buddy Bobby--who does Power Products engines--sent me 12 Flywheels. They needed some stripping, blasting, and burnishing.

Here is the 2nd set of Bonanza wheels for Dragracertpp. They took some blasting and about 2 hours in the burnisher. I had them in the mail 24hrs later.

My buddy Bobby--who does Power Products engines--sent me 12 Flywheels. They needed some stripping, blasting, and burnishing.

Doug D. and Mark C. sent me some parts while back and they showed interest in zinc plating the parts after my blast and burnish. For many steel parts zinc plating was an OEM finish which provided both a decorative finish and rust protection. At the moment I'm driving about 45 minutes away for plating, but I'm seriously considering buying the equipment to do parts up to 90 inches of surface area.

If you're new to this, let me give you an idea of what goes into this type of restoration. It's a lot of work, but the results are worth it.

>Pictures and inspection

>chemical paint stripping

>acid dipping to remove zinc and light rust.

>blasting to get to base metal

>burnishing for decorative luster

>zinc plating for protection ASTM-B633-15

First Doug's parts.

After stripping, blasting, and burnishing.

After Zinc plating.

Final burnishing for Box Muffler. I even found NOS fasteners.

I'll post some more pictures later of Mark's job.

If you're new to this, let me give you an idea of what goes into this type of restoration. It's a lot of work, but the results are worth it.

>Pictures and inspection

>chemical paint stripping

>acid dipping to remove zinc and light rust.

>blasting to get to base metal

>burnishing for decorative luster

>zinc plating for protection ASTM-B633-15

First Doug's parts.

After stripping, blasting, and burnishing.

After Zinc plating.

Final burnishing for Box Muffler. I even found NOS fasteners.

I'll post some more pictures later of Mark's job.

Here is Mark's job. It's a tough one because the rust and corrosion. There appeared to be some remnants of yellow chromated zinc plating on the back of the sprocket hub which has to be removed with acid.

After acid on the plated parts and blasting to the wheels.

Burnished steel parts.

After Zinc plating. Now they are protected and have a nice zinc finish. The luster comes from the burnished steel substrate. If one were to plate blasted parts they would look dull. I think the bright finish is far more attractive.

And finally Mark's burnished Bonanza wheels.

After acid on the plated parts and blasting to the wheels.

Burnished steel parts.

After Zinc plating. Now they are protected and have a nice zinc finish. The luster comes from the burnished steel substrate. If one were to plate blasted parts they would look dull. I think the bright finish is far more attractive.

And finally Mark's burnished Bonanza wheels.

Folks.

I've been a forum member since 2010 and have been involved in vintage karting since 2002. About 3 years ago I bought an ALMCO V3 to help the community with restoration or modification of surface finishes. I own 2 minibikes, my prized 1947 Cushman, as well as 10 vintage karts.

While burnishing a Honda yesterday it occurred to me I hadn't reached out to the MB group and wanted to do that now. Full disclaimer: Burnishing parts is addictive and will help put your projects in the winner’s circle.

I'd like to build a strong thread here with your support. As work comes in I will show before and after pics. If the moderator needs to move this to another location, that's fine with me. This is a service for sale.

Here is a link to some work I've done in the last few months. A more complete portfolio is available on another site which I'll try to link to.

https://www.vintagekartforum.com/showthread.php?tid=982

Thanks.

Sam

View attachment 96276

View attachment 96277

View attachment 96278

View attachment 96279

After

View attachment 96280

View attachment 96281

View attachment 96282

View attachment 96283

I've been a forum member since 2010 and have been involved in vintage karting since 2002. About 3 years ago I bought an ALMCO V3 to help the community with restoration or modification of surface finishes. I own 2 minibikes, my prized 1947 Cushman, as well as 10 vintage karts.

While burnishing a Honda yesterday it occurred to me I hadn't reached out to the MB group and wanted to do that now. Full disclaimer: Burnishing parts is addictive and will help put your projects in the winner’s circle.

I'd like to build a strong thread here with your support. As work comes in I will show before and after pics. If the moderator needs to move this to another location, that's fine with me. This is a service for sale.

Here is a link to some work I've done in the last few months. A more complete portfolio is available on another site which I'll try to link to.

https://www.vintagekartforum.com/showthread.php?tid=982

Thanks.

Sam

View attachment 96276

View attachment 96277

View attachment 96278

View attachment 96279

After

View attachment 96280

View attachment 96281

View attachment 96282

View attachment 96283