I picked up a cheap $200 baja mb165, he said the engine just needed a tune up. The bike was in bad shape, but I was going to strip it down in parts and hide them in a cabinet from my wife.

I Decided to donate a rebuilt MB165 mini bike to a family we know that the two boys father was a policeman killed in the line of duty - so I know their mother would never afford this toy, and it would be good to give a little.

So I was going to buy a new predator 212cc and stick it in, but I wanted the lighting coil from the old baja motor, to run the head light. not a big deal, I watched videos on this so this is no big deal.

After looking at the motor, I'm like I can save $100 and just tune this puppy up, I have a new carb in a box, new air filter and filter box, I just need to order a pull starter, and spark plug. I can just do a tune up and save $75.

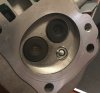

I replaced the carb, new air filter box, added the pull start, went to change the spark plug, and noticed that it was not all the way seated. I backed out the old plug, and noticed the threads are all jacked up... FDKLFJK$#N#!

I should have went with the harbor freight $99 engine (with coupon). Now I am invested, and want to see this engine roar.

Ok, so I began reading on here, how re-thread it. I am not a engine mechanic by any means, and pulling the head off scares me, so I want to attempt the re-thread with the head on.

I bought this cheap $7 from amazon: ABN 14MM Cylinder Head Spark Plug Rethread Kit - it taps a larger thread, and you use a insert. I will use locktight red to make the insert stay put

So my question after all this is:

I want to keep the metal shavings out, I know using a heavy lube on the tapper will get some if I back it out and clean, re-apply lube.

Will it help to remove carb and exhaust and use a air compressor gun and blow out anything? Do I need to turn the crank for the piston to drop 1-2" to have the valves open? maybe pulling the pull start would also blow things out? Or a super strong shop vac sucking it out will do?

will it kill the engine if some of it still is in there, or will it end up in the crankcase in the oil?

I Decided to donate a rebuilt MB165 mini bike to a family we know that the two boys father was a policeman killed in the line of duty - so I know their mother would never afford this toy, and it would be good to give a little.

So I was going to buy a new predator 212cc and stick it in, but I wanted the lighting coil from the old baja motor, to run the head light. not a big deal, I watched videos on this so this is no big deal.

After looking at the motor, I'm like I can save $100 and just tune this puppy up, I have a new carb in a box, new air filter and filter box, I just need to order a pull starter, and spark plug. I can just do a tune up and save $75.

I replaced the carb, new air filter box, added the pull start, went to change the spark plug, and noticed that it was not all the way seated. I backed out the old plug, and noticed the threads are all jacked up... FDKLFJK$#N#!

I should have went with the harbor freight $99 engine (with coupon). Now I am invested, and want to see this engine roar.

Ok, so I began reading on here, how re-thread it. I am not a engine mechanic by any means, and pulling the head off scares me, so I want to attempt the re-thread with the head on.

I bought this cheap $7 from amazon: ABN 14MM Cylinder Head Spark Plug Rethread Kit - it taps a larger thread, and you use a insert. I will use locktight red to make the insert stay put

So my question after all this is:

I want to keep the metal shavings out, I know using a heavy lube on the tapper will get some if I back it out and clean, re-apply lube.

Will it help to remove carb and exhaust and use a air compressor gun and blow out anything? Do I need to turn the crank for the piston to drop 1-2" to have the valves open? maybe pulling the pull start would also blow things out? Or a super strong shop vac sucking it out will do?

will it kill the engine if some of it still is in there, or will it end up in the crankcase in the oil?

Last edited:

:smile:

:smile: