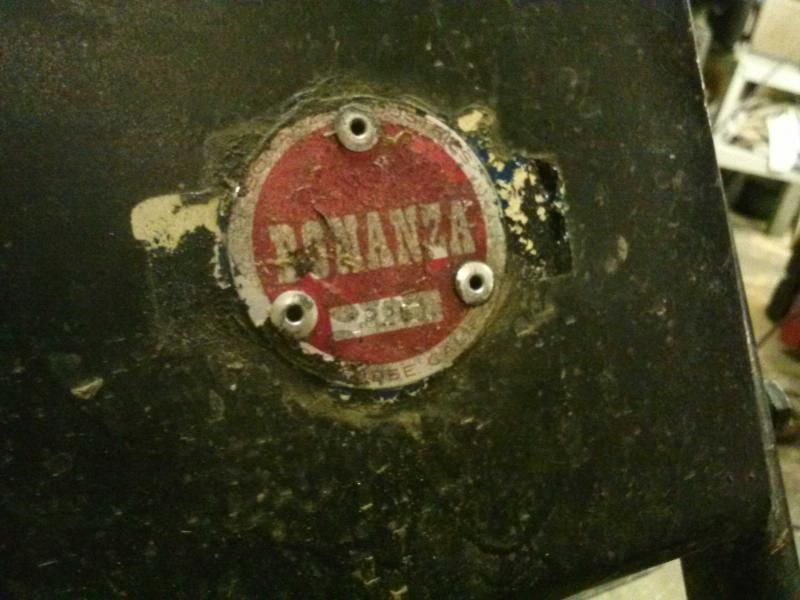

You are right. You need to be on my consulting team. Show me what the originals look like. Here is my badge with the original screws. What do you make of this? Also, I talked to my friend John today and he can make our jack shafts to the 10 5/8 with the snap ring grooves on his lathe. I am going to have him make a few. Let me know if you need one

.

.

Your badge is different than mine. Both of my Bonanza's are 1969 with the kidney bean wheels. The "BONANZA" on both of my badges are raised or embossed. Also the rivet holes on mine are closer to the center than yours. Maybe they changed in 1969 along with the introduction of the kidney bean wheels. Also my badges say "San Jose Calif.,USA. Yours does not say "USA". I have heard stories that the badges used were all in a big bin and were just grabbed off of the top. The badges on the bottom of the barrel so to say may have been there for years because they just kept grabbing the badges on top of the barrel.

Now I have every thing I need to bring to the chrome shop. I will do this early next week. Chrome is getting more and more expensive! They always impress me with the outcome though! Its awesome to drop off rusty ugly pieces of metal and to pick them up looking like jewelry. They always turn out better than expected.