Building a non hemi predator Test Motor

Now that the basic bottom end is together next steps are to measure the in the hole depth for compression calculations and to figure out head gasket thickness so as to have .028-.030 piston to head deck clearance.(squish clearance) Then I will install flywheel, coil, degree wheel and piston stop so I can find TDC install a timing degree strip to the flywheel so I can later check ignition timing.

interesting to see how well the 14cc head will work and if you will have to do more work to it to make it flow as good as a open head. i have read some testing from nrracing on that head and they say it does not work as well as the others. but info i have read doesn't really specify if a person did some rework that it could perform as well ?

ole how many cutters are on the tool your using to enlarging the seat...is it 4. also does it have a morse taper on the end. 2 or a 3 taper?

nice if you had a dyno to go with your head work....:thumbsup:

ole how many cutters are on the tool your using to enlarging the seat...is it 4. also does it have a morse taper on the end. 2 or a 3 taper?

nice if you had a dyno to go with your head work....:thumbsup:

It is a 4 cutter head and is adjustable. The cutters are HSS as they give a finer finish on aluminum They are from Ricardo at New3Acut. He has a special hex driver that fits on the pilot so everything is held concentric to the guide. The shank of the driver is 5/8ths but I had to use an adapter to fit my M-Head Bridgeport's M2 taper. I just got a custom made 1/2 inch driver so I can use a MT-2 1/2 inch collet.

I agree some of the unshrouding on those must be for a big bore motor. I scribe a line around the head gasket that matches the stock bore then put the head on a rotary table and with a ball end mill go to the gasket line. One of the nice things of these heads is that the short side is against the cylinder wall so the shrouding does not have as much of an effect as the short side as it does in a car because the short side moves less air around the valve as the long side does.

Today I added a timing tape to the flywheel installed and set up my degree wheel to fine TDC and degree in the cam. I am going to try a genuine Honda coil. I have read these have less high rpm retard but have no idea if it is really true. The coil is much smaller than the stock coil and maybe it has less inductance than the stock coil so maybe that is why they retard less, but I would expect less spark energy. We shall see, I am also using a non resistor plug cap. The cam degreed in about a degree and a half advanced so that if fine for me. I also checked total duration so I have input to pipe max to calculate exhaust length.

I also added a neo bar magnet to one of the drain plugs got that tio from a OldMiniBikes member a while ago.

Today I added a timing tape to the flywheel installed and set up my degree wheel to fine TDC and degree in the cam. I am going to try a genuine Honda coil. I have read these have less high rpm retard but have no idea if it is really true. The coil is much smaller than the stock coil and maybe it has less inductance than the stock coil so maybe that is why they retard less, but I would expect less spark energy. We shall see, I am also using a non resistor plug cap. The cam degreed in about a degree and a half advanced so that if fine for me. I also checked total duration so I have input to pipe max to calculate exhaust length.

I also added a neo bar magnet to one of the drain plugs got that tio from a OldMiniBikes member a while ago.

Last edited:

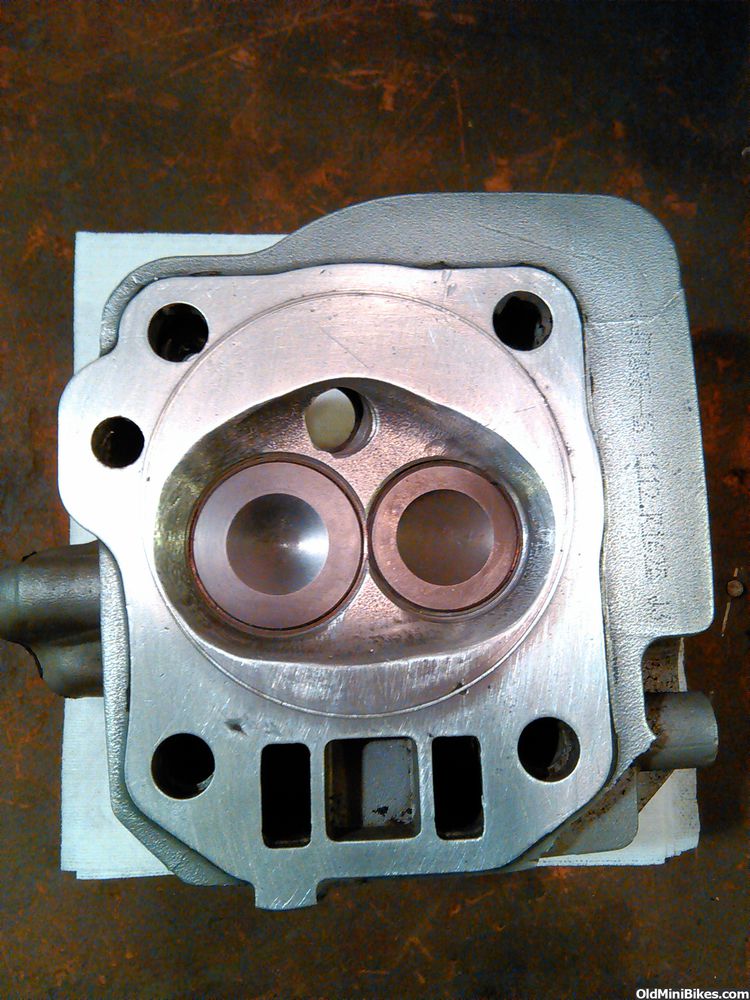

Just finished cutting the 32mm counterbore on the 14cc head, two down one to go.

To install the seats I will have to heat the head on a hotplate while the installation tool sits in the freezer. The driver fits on a pilot so that the seat goes into the counterbore straight. Some pics of the cylinder head toolkit, the driver with 28 and 32mm adapters and how it sits on the pilot which is inserted in the valve guide.

To install the seats I will have to heat the head on a hotplate while the installation tool sits in the freezer. The driver fits on a pilot so that the seat goes into the counterbore straight. Some pics of the cylinder head toolkit, the driver with 28 and 32mm adapters and how it sits on the pilot which is inserted in the valve guide.